This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

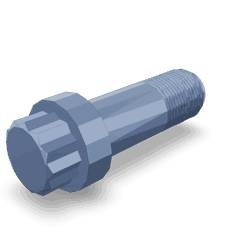

The Twelve Point Cap Screw, identified by Part #206030, is a component manufactured by Cummins, a well-established name in the commercial truck industry. This screw is integral to the assembly and maintenance of various truck components, ensuring the structural integrity and operational efficiency of commercial vehicles.

Basic Concepts of Twelve Point Cap Screws

A Twelve Point Cap Screw is a type of fastener characterized by its twelve-sided head, which provides a greater contact area than traditional hex screws. This design allows for more torque to be applied without rounding off the edges, making it suitable for high-stress applications. In mechanical assemblies, these screws are used to secure components that require a strong, durable connection 1.

Purpose of the 206030 Twelve Point Cap Screw in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is utilized in applications where high torque and resistance to loosening are required. Specific uses include securing engine components, transmission parts, and chassis assemblies. Its design ensures that it can withstand the vibrations and stresses encountered in heavy-duty truck operations 2.

Key Features of the 206030 Twelve Point Cap Screw

The 206030 Twelve Point Cap Screw is designed with several features that enhance its performance and durability. It is constructed from high-strength materials, typically alloy steel, which provides excellent tensile strength and resistance to wear. The twelve-point head design allows for greater torque application without the risk of stripping. Additionally, the screw may feature a corrosion-resistant coating to prolong its lifespan in harsh environments 3.

Benefits of Using the 206030 Twelve Point Cap Screw

Using the 206030 Twelve Point Cap Screw offers several advantages. Its design allows for improved torque application, ensuring that components are securely fastened. The resistance to loosening under vibration makes it ideal for use in dynamic environments. Furthermore, its durability in harsh operating conditions contributes to the longevity of the truck’s components, reducing the need for frequent replacements.

Installation and Usage Guidelines

Proper installation of the 206030 Twelve Point Cap Screw is crucial for ensuring a secure fit. It should be installed using a torque wrench to apply the manufacturer-specified torque, which ensures that the screw is tightened to the correct level without over-tightening. Best practices include cleaning the mating surfaces before installation and using a thread lubricant to prevent seizing. It is also important to follow any specific guidelines provided by Cummins for the application in question.

Troubleshooting Common Issues

Common issues with Twelve Point Cap Screws include stripping and seizing. Stripping can occur if excessive torque is applied, while seizing may happen if the screw is not properly lubricated during installation. To address these issues, it is recommended to use the correct torque specifications and to apply a suitable lubricant. If a screw becomes seized, careful heating and cooling techniques may be employed to loosen it without causing damage.

Maintenance Tips

Regular maintenance of the 206030 Twelve Point Cap Screw can prolong its life and ensure continued performance. Inspection routines should include checking for signs of wear, corrosion, or loosening. If any issues are detected, the screw should be tightened or replaced as necessary. Additionally, keeping the surrounding area clean and free of debris can prevent contamination that may lead to premature failure.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture.

Twelve Point Cap Screw 206030 in Cummins Engines

The Twelve Point Cap Screw 206030, manufactured by Cummins, is a critical component in several of their engine models. This screw is designed to provide robust fastening solutions, ensuring secure connections in various engine assemblies.

Application in Specific Engines

QSK38 CM2150 MCRS and QSK50 CM2150 MCRS

In the QSK38 CM2150 MCRS and QSK50 CM2150 MCRS engines, the Twelve Point Cap Screw 206030 is utilized in several key areas. These include securing the cylinder heads to the engine block, fastening various brackets and supports, and ensuring the integrity of the engine’s mounting system. The screw’s design allows for precise torque application, which is crucial for maintaining the structural integrity of these components under high operational stresses.

QSK50 CM2350 K108

For the QSK50 CM2350 K108 engine, the Twelve Point Cap Screw 206030 plays a similar role. It is employed in securing critical engine parts, such as the turbocharger housing and other auxiliary components. The screw’s ability to withstand high torque and its precise threading make it ideal for these applications, ensuring that all parts remain tightly fastened and aligned.

Grouping of Engines

The QSK38 CM2150 MCRS and QSK50 CM2150 MCRS engines share a common platform and many similar components, including the use of the Twelve Point Cap Screw 206030. This commonality allows for easier maintenance and repair, as technicians can use the same fasteners across different engine models. The QSK50 CM2350 K108, while part of the same family, incorporates this screw in slightly different configurations to accommodate its unique design and operational requirements.

Importance of the Screw

The Twelve Point Cap Screw 206030 is essential in these engines due to its ability to provide a secure and reliable fastening solution. The screw’s twelve-point design allows for better grip and easier torque application, which is critical in high-stress environments. Its use in various engine components ensures that the engine operates smoothly and efficiently, with all parts remaining securely fastened under operational loads.

Part 206030 Twelve Point Cap Screw Component Usage

The Part 206030 Twelve Point Cap Screw is integral to the assembly and maintenance of various engine systems, particularly in the automotive and industrial sectors. Its design and functionality make it suitable for applications where secure fastening is required under high stress and vibration conditions.

Compressor Systems

In compressor systems, the Twelve Point Cap Screw is often used to secure the compressor housing to the engine block or frame. This ensures that the compressor operates efficiently by maintaining alignment and reducing the risk of leaks. The screw’s twelve-point design provides enhanced torque application, minimizing the chance of cam-out during tightening, which is essential in high-pressure environments.

Refrigerant Systems

Within refrigerant systems, the Twelve Point Cap Screw plays a role in securing components such as the condenser, evaporator, and various refrigerant lines. These systems require precise and reliable fastening to prevent refrigerant leaks, which can lead to system inefficiency and environmental concerns. The screw’s robust design ensures that connections remain tight, even under fluctuating temperatures and pressures.

Bulk Parts List Integration

When considering a bulk parts list for engine maintenance or assembly, the inclusion of the Twelve Point Cap Screw is standard. Its versatility allows it to be used across different subsystems, from securing brackets and mounts to fastening critical engine components. This universality makes it a staple in any comprehensive parts inventory for engineers and mechanics.

Conclusion

The 206030 Twelve Point Cap Screw is a fundamental component in ensuring the integrity and performance of various engine systems. Its reliable fastening capabilities contribute to the overall efficiency and durability of these systems, making it an essential part in the maintenance and operation of commercial trucks and industrial engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.