This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

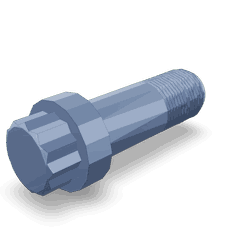

The 206042 Twelve Point Cap Screw by Cummins is a specialized fastener designed for use in commercial truck applications. Its purpose is to provide secure and reliable fastening in various truck components, ensuring the integrity and performance of mechanical assemblies. The significance of this part lies in its ability to withstand high stress and torque, contributing to the overall durability and efficiency of commercial trucks.

Basic Concepts and Functionality

Twelve point cap screws are a type of fastener characterized by their hexagonal socket with twelve sides, which offers several advantages over traditional six-point screws. This design allows for better torque application and reduces the risk of cam-out, where the tool slips out of the fastener head 1. Twelve point cap screws are commonly used in mechanical assemblies where high torque and secure fastening are required.

Role in Truck Operations

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various truck components, including engine mounts, transmission housings, and chassis assemblies. By providing a secure and stable connection, this cap screw helps maintain the structural integrity and performance of these critical components.

Key Features

The 206042 features a robust design with a twelve-sided socket head, which enhances torque application and reduces the likelihood of cam-out. It is typically made from high-strength materials such as alloy steel, ensuring durability and resistance to wear. The screw’s design includes a threaded shaft that allows for secure fastening into corresponding components.

Benefits

The advantages of using this part include improved torque application due to its twelve-sided design, which provides more contact points than a traditional six-point screw. This results in a more secure fastening and reduced risk of the tool slipping during installation or removal 2. Additionally, the enhanced fastening security contributes to the overall reliability and longevity of the truck’s mechanical assemblies.

Installation Guidelines

Proper installation of the 206042 involves several steps to ensure optimal performance and longevity. Begin by selecting the appropriate tool, such as a twelve-point socket wrench, to match the screw’s head. Apply the screw to the designated location, ensuring it is aligned correctly with the threaded hole. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, which helps prevent over-tightening or under-tightening. Follow best practices by inspecting the installation site for any signs of damage or misalignment before final tightening 3.

Troubleshooting and Maintenance

Common issues with twelve point cap screws include loosening over time due to vibration or thermal expansion, and corrosion in harsh environments. To address these issues, regular inspections should be conducted to check for any signs of wear or damage. If loosening is detected, re-tighten the screw to the specified torque settings. In cases of corrosion, cleaning the screw and applying a corrosion-resistant coating can help prolong its lifespan. Maintenance tips include using the correct tools during installation and removal to avoid damaging the screw or the fastener head.

Manufacturer Overview - Cummins

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive industry, particularly for producing high-quality components for commercial vehicles. Founded in 1919, Cummins has built a legacy of innovation and excellence, providing reliable and durable parts that meet the demanding requirements of commercial truck applications. Their commitment to quality and performance is evident in their extensive range of products, including the 206042.

Role of Part 206042 Twelve Point Cap Screw in Engine Systems

The 206042 is instrumental in ensuring the secure assembly and reliable operation of various engine components. Its application spans across multiple systems, contributing to the overall integrity and performance of the engine.

Intake Manifold and Intake Manifold Mounting

In the intake manifold system, the Twelve Point Cap Screw is used to fasten the intake manifold to the engine block. This secure attachment is vital for maintaining the airtight seal necessary for optimal air-fuel mixture delivery. Additionally, in the intake manifold mounting kit, these screws ensure that the manifold is correctly positioned and tightly secured, preventing any potential leaks that could affect engine performance.

Powertrain Control Module (PDC) and Lower Engine Gasket Set

When installing the Powertrain Control Module (PDC), the Twelve Point Cap Screw is employed to mount the module securely to its designated location. This ensures that the PDC remains stable and protected from vibrations, which could otherwise interfere with its operation. In the lower engine gasket set, these screws are used to hold gaskets in place, ensuring a proper seal between engine components, which is essential for maintaining compression and preventing oil or coolant leaks.

Mounting Intercooler and Noise Mounting Air Manifold Panel

For the mounting intercooler, the Twelve Point Cap Screw plays a key role in attaching the intercooler to the engine bay. This secure fitting is important for the intercooler’s efficiency in cooling the intake air, which directly impacts engine performance. Similarly, in the noise mounting air manifold panel, these screws are used to attach the panel, helping to reduce engine noise and vibrations, thus contributing to a quieter and more stable engine operation.

Starting Aid Kit

In the starting aid kit, the Twelve Point Cap Screw is utilized to secure components that assist in the engine’s starting process. This could include attaching electrical connections or mechanical parts that are essential for the initial cranking and ignition sequence. The secure fastening provided by these screws ensures that all components function correctly during startup, enhancing the reliability of the engine’s starting system.

Conclusion

The 206042 Twelve Point Cap Screw by Cummins is a critical component in the maintenance and operation of commercial trucks. Its robust design, high-strength material, and secure fastening capabilities make it an essential part for various engine and truck components. Proper installation, regular maintenance, and understanding its role in different systems ensure the longevity and performance of the truck’s mechanical assemblies.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.