This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

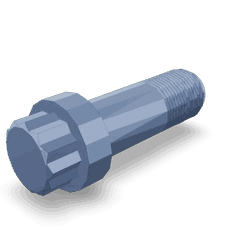

The Cummins Twelve Point Cap Screw (Part #206488) is a specialized fastener designed for use in commercial truck maintenance and operation. This component is integral to ensuring the secure assembly of various truck components, contributing to the overall reliability and performance of commercial vehicles. Its design and material composition are tailored to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener characterized by its hexagonal socket head, which provides twelve points of contact. This design differs from traditional hex cap screws, which offer only six points of contact. The increased number of contact points enhances the screw’s resistance to cam-out, making it more reliable in high-torque applications 2. Twelve point cap screws are commonly used in mechanical assemblies where secure fastening and resistance to loosening are essential.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is utilized in various truck components, including engine assemblies, transmission systems, and chassis structures. The screw ensures that critical parts remain securely fastened, which is vital for the safe and efficient operation of the vehicle. Its applications span across different truck models and systems, providing a versatile solution for fastening needs 3.

Key Features

The Twelve Point Cap Screw (Part #206488) features a robust design that includes a hexagonal socket head with twelve points of contact. This design enhances the screw’s torque application capabilities and reduces the risk of cam-out. The screw is typically made from high-strength materials, such as alloy steel, to ensure durability and resistance to wear. Additionally, it may include features like a zinc plating or other coatings to protect against corrosion, further enhancing its performance in harsh environments 1.

Benefits

This part offers several benefits in fastening applications. Its design allows for improved torque application, ensuring that components are securely fastened without the risk of stripping or cam-out. The enhanced security provided by the twelve points of contact reduces the likelihood of fastening failures, which can be critical in heavy-duty truck applications. Additionally, the screw’s material composition and protective coatings contribute to its longevity and reliability in demanding conditions 2.

Installation Guidelines

Proper installation of the Twelve Point Cap Screw (Part #206488) is crucial to ensure secure and reliable fastening. The following guidelines should be observed:

- Ensure the mating surface is clean and free of debris.

- Use the appropriate socket tool to engage the screw, aligning it with the designated hole.

- Apply torque gradually, following the recommended torque specifications provided by the manufacturer to avoid over-tightening or under-tightening.

- Double-check the fastening to ensure it is secure and properly aligned 3.

Troubleshooting and Maintenance

Common issues with twelve point cap screws may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues promptly. If a screw shows signs of wear or corrosion, it should be replaced to maintain the integrity of the fastening. Additionally, ensuring that all fasteners are torqued to the manufacturer’s specifications during installation can prevent many common problems 1.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of customers in various sectors, including transportation, construction, and agriculture. Cummins’ commitment to excellence is reflected in its extensive product lineup, which includes high-performance engines, components, and aftermarket parts.

Twelve Point Cap Screw 206488 in Cummins Engines

The Twelve Point Cap Screw 206488, manufactured by Cummins, is a critical component in several of their engine models. This screw is designed to provide robust fastening, ensuring secure connections in various engine assemblies.

K19 and K38 Engines

In the K19 and K38 engines, the 206488 cap screw is utilized in several key areas. These engines, known for their reliability and efficiency, require precise fastening to maintain structural integrity and operational performance. The screw’s twelve-point design allows for better grip and torque application, which is essential for the high-stress environments within these engines 2.

K50 Engine

The K50 engine also incorporates the 206488 cap screw in its construction. This engine, part of Cummins’ lineup, benefits from the screw’s ability to withstand significant mechanical stress. The cap screw’s design ensures that components remain securely fastened, contributing to the engine’s overall durability and longevity 3.

QSK19 CM500 and QSK19 CM850 MCRS Engines

For the QSK19 CM500 and QSK19 CM850 MCRS engines, the 206488 cap screw plays a vital role in maintaining the integrity of the engine’s components. These engines are designed for heavy-duty applications, and the screw’s strength and reliability are crucial in such demanding conditions. The twelve-point design facilitates easier and more efficient tightening, which is beneficial in complex engine assemblies 1.

QSK50 CM2150 MCRS Engine

In the QSK50 CM2150 MCRS engine, the 206488 cap screw is used in various critical applications. This engine, known for its power and efficiency, relies on the screw’s ability to provide secure fastening in high-stress environments. The screw’s design ensures that components remain tightly secured, contributing to the engine’s overall performance and reliability 2.

Role of Part 206488 Twelve Point Cap Screw in Engine Systems

The part 206488 Twelve Point Cap Screw is integral to the secure assembly and operation of various engine components. Its application ensures the stability and efficiency of the engine system by fastening critical parts together.

In the adapter assemblies, this cap screw is used to fasten the adapter to the engine block, ensuring a secure connection that can withstand operational stresses.

For the front drive arrangement, the Twelve Point Cap Screw is employed to attach the front drive components, maintaining alignment and reducing the risk of misalignment under dynamic conditions.

In turbocharger systems, it plays a role in securing the turbocharger to its mounting points, which is essential for efficient airflow management and power output.

The damper and vibration control components also utilize this cap screw to attach to the engine, helping to absorb vibrations and ensure smooth operation.

In the exhaust manifold / turbocharger setup, the cap screw is used to secure the manifold to the turbocharger, ensuring a tight seal that prevents exhaust leaks and maintains engine efficiency.

For the front power take-off (PTO) and front PTO adapter, the Twelve Point Cap Screw ensures these components are firmly attached to the engine, allowing for the transfer of power to auxiliary equipment without failure.

In the front support mounting, this cap screw is critical for securing the front support structure, which bears the weight and operational stresses of the engine.

The pulley crank and pump assemblies also benefit from the use of this cap screw, as it ensures these rotating components are securely fastened, reducing the likelihood of component failure during operation.

Lastly, in the fuel system components, the Twelve Point Cap Screw is used to secure fuel lines and fittings, ensuring a leak-free connection that is vital for safe and efficient engine operation 3.

Conclusion

The Cummins Twelve Point Cap Screw (Part #206488) is a critical component in the maintenance and operation of commercial trucks and engines. Its robust design, high-strength material, and protective coatings make it an ideal choice for heavy-duty applications. Proper installation and regular maintenance are essential to ensure the longevity and reliability of this fastener in demanding environments.

-

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ ↩ ↩ ↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014

↩ ↩ ↩ ↩ -

Engine Testing: Theory and Practice: Third Edition, A.J. Martyr, SAE International, 2007

↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.