This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 207507 Twelve Point Cap Screw is a specialized fastener designed for use in commercial truck maintenance and operation. This component is integral to ensuring the secure assembly of various truck components, contributing to the overall reliability and performance of the vehicle.

Basic Concepts of Twelve Point Cap Screws

A twelve point cap screw is a type of fastener characterized by its hexagonal socket head, which provides a larger contact area compared to traditional hex-head screws. This design allows for more torque to be applied without the risk of cam-out, making it suitable for high-stress applications. Unlike other fasteners, the twelve point configuration reduces the likelihood of stripping and provides a more secure fit 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation and maintenance of commercial trucks. It is commonly used in applications where high torque and secure fastening are required, such as in engine components, transmission systems, and chassis assemblies. Its design ensures that critical parts remain firmly in place, even under demanding conditions 2.

Key Features

The Cummins 207507 Twelve Point Cap Screw features a robust design that includes a twelve-sided socket head, which enhances torque application and reduces the risk of rounding. It is typically made from high-strength materials, such as alloy steel, to ensure durability and resistance to wear. The screw’s precise threading and high-quality finish contribute to its reliable performance in various truck components.

Benefits

Using the Cummins 207507 Twelve Point Cap Screw offers several advantages. Its design allows for improved torque application, which is crucial in high-stress environments. The screw’s resistance to stripping ensures that it maintains a secure hold, even when subjected to significant force. Additionally, the twelve-point head provides enhanced security in fastening applications, reducing the likelihood of loosening over time 3.

Installation Guidelines

Proper installation of the Cummins 207507 Twelve Point Cap Screw is vital to ensure optimal performance and longevity. It is recommended to use the appropriate torque wrench to apply the correct amount of torque, as specified by the manufacturer. This ensures that the screw is tightened to the proper level without over-tightening, which could lead to damage. Additionally, using a socket wrench designed for twelve-point screws will help prevent cam-out and ensure a secure fit.

Troubleshooting and Maintenance

Common issues with the Cummins 207507 Twelve Point Cap Screw may include loosening or corrosion. Regular inspection and maintenance can help identify these issues early. If loosening is detected, re-tightening the screw to the manufacturer’s specified torque is recommended. To prevent corrosion, applying a suitable anti-seize compound during installation can be beneficial. Additionally, keeping the screw and surrounding areas clean and free of debris will help prolong its lifespan.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the realm of diesel engines and related components. The company is committed to innovation, quality, and customer satisfaction, ensuring that its products meet the highest standards of performance and reliability.

Engine Compatibility with Twelve Point Cap Screw 207507 by Cummins

The Twelve Point Cap Screw 207507, manufactured by Cummins, is a critical component in the assembly and maintenance of various Cummins engines. This screw is designed to provide robust fastening capabilities, ensuring secure connections in high-stress environments typical of engine assemblies.

K38 Engine

In the K38 engine, the Twelve Point Cap Screw 207507 is utilized in several key areas. Its high strength and precise threading make it ideal for securing components that are subject to significant mechanical stress. This includes fastening various engine mounts, brackets, and other structural parts that are essential for maintaining the engine’s integrity and performance.

K50 Engine

Similarly, in the K50 engine, the Twelve Point Cap Screw 207507 plays a vital role. Given the K50’s design and operational requirements, this screw is employed in multiple locations to ensure that all parts are tightly and securely fastened. Its application extends to securing engine blocks, cylinder heads, and other critical assemblies, ensuring that the engine operates smoothly and efficiently.

Grouped Application

For both the K38 and K50 engines, the Twelve Point Cap Screw 207507 is a preferred choice due to its superior performance characteristics. The screw’s design allows for easy installation and removal, which is crucial during routine maintenance and repairs. Its use in these engines highlights Cummins’ commitment to quality and reliability, ensuring that each component performs optimally under demanding conditions.

Role of Part 207507 Twelve Point Cap Screw in Engine Systems

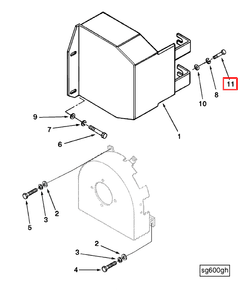

In the intricate assembly of engine systems, the Part 207507 Twelve Point Cap Screw is instrumental in ensuring the secure and reliable fastening of various components. This screw is commonly utilized in the accessory drive mounting system, where it plays a significant role in maintaining the structural integrity and alignment of the accessory drive components. By securely fastening the accessory drive to the engine block or other mounting surfaces, it ensures that the drive operates efficiently and without undue stress or movement.

Additionally, the Twelve Point Cap Screw is integral to the arrangement and stability of the damper guard. In this application, it is used to fasten the damper guard to the engine, providing a secure attachment that protects the damper from external elements and potential damage. The screw’s design allows for a snug fit, which is essential for the damper guard’s function in reducing vibrations and noise within the engine compartment.

Furthermore, in the context of the damper guard, the Part 207507 is employed to ensure that the guard remains firmly in place under varying engine operating conditions. This is particularly important in high-vibration environments, where the stability of the damper guard is paramount to the overall performance and longevity of the engine.

The use of the Twelve Point Cap Screw in these applications underscores its importance in maintaining the precision and reliability of engine systems. Its role in securing critical components ensures that the engine operates smoothly, efficiently, and with minimal risk of component failure or misalignment.

Conclusion

The Cummins 207507 Twelve Point Cap Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, high-strength materials, and precise threading make it ideal for high-stress applications, ensuring secure and reliable fastening of critical components. Proper installation and maintenance are essential to maximize its performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.