Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

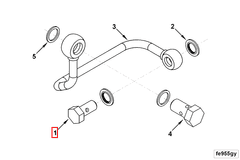

The 2830360 Banjo Connector Screw, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces a wide range of parts and systems that contribute to the efficiency and reliability of commercial vehicles. This Cummins part is significant in maintaining the integrity of fluid systems within trucks, ensuring optimal performance and longevity of the vehicle 1.

Basic Concepts and Functionality

A Banjo Connector Screw is a type of fitting used to connect hoses or pipes to various components within a truck’s system. The 2830360 model by Cummins features a basic design that includes a threaded body and a sealing surface. Its functionality is based on principles of fluid dynamics, where it allows for the controlled transfer of fluids such as hydraulic oil or fuel. The sealing mechanism is crucial for preventing leaks, which could lead to system failure or inefficiency 2.

Purpose and Role in Truck Operation

The 2830360 Banjo Connector Screw plays a specific role in the operation of commercial trucks by facilitating the connection between hoses and components in hydraulic and fuel systems. Its design ensures a secure and leak-free connection, which is vital for maintaining system integrity and performance. Proper function of this component is necessary for the efficient operation of the truck’s systems, contributing to overall vehicle reliability 3.

Key Features

The 2830360 Banjo Connector Screw is characterized by several key features that enhance its functionality and durability. It is made from high-quality materials that resist corrosion and wear, ensuring a long service life. The design includes precise threading for a secure fit and a robust sealing surface to prevent leaks. Additionally, the connector screw may feature unique attributes such as anti-vibration properties or easy-to-use installation features that further contribute to its effectiveness in commercial truck applications.

Benefits

Using the 2830360 Banjo Connector Screw offers several benefits, including improved system reliability due to its secure and leak-free connections. The design of the screw allows for ease of installation, reducing downtime during maintenance procedures. Furthermore, its durability and resistance to wear contribute to lower maintenance costs and increased efficiency in truck operations.

Installation and Usage Guidelines

Proper installation of the 2830360 Banjo Connector Screw involves several steps to ensure a secure and leak-free connection. It is recommended to use the appropriate tools for tightening to the specified torque, which can be found in the manufacturer’s guidelines. Careful attention should be paid to the sealing surfaces to ensure they are clean and free from debris before installation. Following these guidelines will help in achieving a reliable connection that contributes to the overall performance of the truck’s systems.

Troubleshooting and Maintenance

Common issues with Banjo Connector Screws may include leaks or loose connections. Troubleshooting steps involve checking the tightness of the screw, inspecting the sealing surfaces for damage, and ensuring that the hoses are properly seated. Regular maintenance practices, such as periodic checks for wear and corrosion, can help in identifying potential issues before they lead to system failure. Replacement guidelines should be followed when signs of wear or damage are detected to maintain optimal performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes components and systems that are designed to enhance the performance, efficiency, and reliability of commercial vehicles. Cummins’ dedication to quality and innovation is evident in their manufacturing processes and the durability of their products.

Cummins Banjo Connector Screw 2830360 in Engine Applications

The Cummins Banjo Connector Screw 2830360 is a critical component in various engine systems, ensuring secure and leak-proof connections for hydraulic or fuel lines. This part is integral to maintaining the integrity of the engine’s fluid systems, providing a reliable method for attaching hoses to the engine’s ports.

Integration in Engine Models

The 2830360 Banjo Connector Screw is utilized in several Cummins engine models, including but not limited to:

- B6.7S: This engine model incorporates the 2830360 screw to secure connections in its hydraulic and fuel systems. The screw’s design ensures that the connections remain tight and leak-free, which is crucial for the engine’s performance and longevity.

Application in Engine Systems

In the B6.7S engine, the 2830360 screw is typically used in the following systems:

- Fuel Delivery System: Ensuring that fuel lines are securely attached to the engine’s fuel injectors and other components.

- Hydraulic Systems: Securing hydraulic lines that are essential for the operation of various engine components, such as the variable geometry turbocharger (VGT).

The screw’s design allows for easy installation and removal, making maintenance and repairs more efficient. Its robust construction ensures that it can withstand the high pressures and temperatures found in engine environments.

Role of Part 2830360 Banjo Connector Screw in Engine Systems

The Part 2830360 Banjo Connector Screw is an essential component in various engine systems, facilitating the secure connection and efficient operation of several critical elements.

In the Air Fuel Control Tube system, this banjo connector screw ensures a tight and reliable seal between the tube and its mating components. This seal is vital for maintaining the precise air-fuel ratio necessary for optimal engine performance and emissions control. The secure connection prevents any leaks that could disrupt the balance of air and fuel, ensuring that the engine operates smoothly and efficiently.

Within the broader Connection framework of engine systems, the banjo connector screw plays a pivotal role in joining different components, such as hoses, pipes, and sensors. Its design allows for easy installation and removal while maintaining a robust seal, which is essential for the integrity of the system. This reliability is particularly important in high-pressure and high-temperature environments typical of engine compartments.

In the context of Air Transfer systems, the banjo connector screw is used to connect various air passages, ensuring that air flows unimpeded from one component to another. This is important for systems like the Positive Crankcase Ventilation (PCV) or the secondary air injection system, where the efficient transfer of air is necessary for reducing emissions and improving engine performance.

For Plumbing applications within the engine, the banjo connector screw is often employed to connect fuel lines, coolant passages, and other fluid transfer systems. Its ability to create a leak-proof connection is essential for maintaining the pressure and flow rates required for these systems to function correctly. This is particularly important in fuel injection systems, where precise fuel delivery is critical for engine performance.

Lastly, in the Air Fuel Control system, the banjo connector screw ensures that all components involved in monitoring and adjusting the air-fuel mixture are securely connected. This includes connections to sensors, actuators, and control units. The reliable sealing provided by the banjo connector screw helps maintain the accuracy of these measurements and adjustments, contributing to the overall efficiency and performance of the engine.

Conclusion

The 2830360 Banjo Connector Screw by Cummins is a vital component in the maintenance and operation of commercial truck and engine systems. Its design and functionality ensure secure, leak-free connections that are essential for the efficient operation of hydraulic and fuel systems. The use of high-quality materials and precise engineering in this Cummins part contributes to its durability and reliability, making it a critical element in the performance and longevity of commercial vehicles.

-

Martyr, A.J. (2007). Engine Testing: Theory and Practice: Third Edition. SAE International.

↩ -

Watson, Ben (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Brach, R. Matthew (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.