2864899

Connecting Rod Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

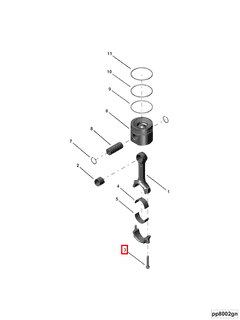

The Cummins 2864899 Connecting Rod Cap Screw is a critical component in heavy-duty truck engines, designed to secure the connecting rod to the crankshaft. This part ensures the structural integrity and operational efficiency of the engine, facilitating the conversion of linear motion into rotational motion 1.

Function and Operation

This Cummins part operates by fastening the connecting rod cap to the connecting rod, which is attached to the crankshaft. This secure connection is essential for transmitting force from the piston to the crankshaft, enabling the engine’s power stroke. The screw must endure high stress and vibration, highlighting the importance of its design and material 2.

Key Features

The 2864899 is engineered with specific design and material specifications to ensure durability, strength, and resistance to wear and fatigue. Typically made from high-grade steel, it provides the necessary tensile strength and hardness for demanding engine conditions. The screw’s design may include a precise thread pitch and a robust head configuration to enhance fastening capabilities and resistance to loosening 3.

Benefits

Using the Cummins 2864899 offers several advantages. It ensures a secure and stable connection between the connecting rod and crankshaft, contributing to enhanced engine performance and balance. The screw’s durability and resistance to wear and fatigue also contribute to the engine’s reliability and longevity, reducing the risk of engine failure due to connecting rod issues.

Installation and Maintenance

Proper installation and maintenance of this part are crucial for optimal performance and longevity. Installation should adhere to manufacturer-specified torque settings to achieve the correct tension without over-tightening. Regular inspections should be conducted to check for signs of wear, corrosion, or loosening. Maintenance intervals may vary depending on the engine’s operating conditions, but following recommended schedules helps prevent unexpected failures.

Troubleshooting

Common issues with Connecting Rod Cap Screws include loosening, corrosion, and damage. Troubleshooting involves a thorough inspection of the screw and its surrounding components. If loosening is detected, re-torquing to the manufacturer’s specifications may resolve the issue. Corrosion can be addressed through cleaning and, if necessary, replacement of the affected components. Damage to the screw may require replacement to ensure the engine’s continued safe operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for manufacturing high-quality engine components for commercial vehicles. The company’s commitment to innovation, quality, and customer satisfaction underscores its position as a trusted provider in the automotive industry.

Compatibility

The Cummins Connecting Rod Cap Screw, identified by part number 2864899, is compatible with various Cummins engine models, including:

-

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

-

ISZ13 Series

- ISZ13 CM2150 Z105

-

QSX11.9 Series

- QSX11.9 CM2250 ECF

-

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

-

Z13 Series

- Z13 Z108G

This part is engineered to meet the specific requirements of these engine models, ensuring compatibility and optimal performance across the range.

Role in Engine Systems

The 2864899 plays a vital role in the secure assembly and operation of several key engine components. It primarily functions to fasten the connecting rod cap to the connecting rod, ensuring the stability and alignment of the connecting rod and piston assembly. This securement is crucial for the efficient transfer of force from the piston to the crankshaft, a fundamental aspect of engine operation.

In the context of the Cylinder Block Kit, the connecting rod cap screw maintains the structural integrity of the engine block. By securing the connecting rod to the crankshaft, it ensures that the reciprocating motion of the pistons is effectively translated into rotational motion of the crankshaft, contributing to the overall stability and performance of the engine block.

The Cylinder Head and Head components also benefit from the secure fastening provided by the connecting rod cap screw. A well-secured connecting rod ensures that the forces generated during combustion are efficiently managed, reducing the risk of mechanical stress on the cylinder head and head components. This is particularly important in high-performance engines where the forces involved are significantly greater.

In engines equipped with Injector systems, the role of the connecting rod cap screw becomes even more pronounced. The precise timing and force delivery required for fuel injection depend on the stable operation of the connecting rod and piston assembly. Any instability in this area could lead to inefficiencies in fuel delivery and combustion, impacting the engine’s performance and fuel economy.

The Camshaft is another component indirectly influenced by the connecting rod cap screw. The camshaft operates in sync with the crankshaft, and any instability in the crankshaft’s rotation—caused by an improperly secured connecting rod—can affect the timing and efficiency of the camshaft’s operation. This can lead to issues such as valve timing errors, which can significantly impact engine performance.

For Performance Parts and Performance-oriented engines, the connecting rod cap screw is particularly important. These engines often operate under more extreme conditions, requiring components to be securely fastened to handle higher stresses and forces. The connecting rod cap screw, therefore, plays a key role in ensuring that these high-performance engines operate smoothly and efficiently.

Lastly, in engines with Piston Cooling Nozzles, the secure operation of the connecting rod is essential. Efficient piston cooling is critical for maintaining engine performance and longevity, especially under high-stress conditions. A securely fastened connecting rod ensures that the piston’s movement is consistent and stable, facilitating effective cooling and reducing the risk of overheating.

Conclusion

The Cummins 2864899 Connecting Rod Cap Screw is a fundamental component in the assembly and operation of various engine systems. Its role in securing the connecting rod and piston assembly has a ripple effect on the performance and stability of other engine components, making it a key element in the overall engine design and functionality.

-

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.