This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2873989 Fracture-Resistant Screw by Cummins is a specialized component designed to enhance the durability and reliability of heavy-duty truck systems. This screw is engineered to withstand significant mechanical stress, making it a vital part in the maintenance and operation of heavy-duty trucks. Its role is to secure critical components, ensuring they remain intact under demanding conditions.

Basic Concepts of Fracture-Resistant Screws

Fracture-resistant screws are designed to resist breaking under stress, which is particularly important in mechanical applications where components are subject to high loads and vibrations. These screws are typically made from materials that offer superior strength and durability. They function by providing a secure fastening solution that can endure the rigors of heavy-duty use, thus playing a role in maintaining the integrity of mechanical systems 1.

Purpose and Role in Truck Operation

The 2873989 Fracture-Resistant Screw plays a specific role in the operation and maintenance of heavy-duty trucks by securing components that are critical to the truck’s performance. It ensures that parts remain firmly in place, even under extreme conditions, thereby contributing to the overall reliability and safety of the vehicle. This screw is often used in areas where traditional screws might fail due to the high stress and vibration encountered in heavy-duty applications.

Key Features

The 2873989 Fracture-Resistant Screw boasts several key features that enhance its performance. It is composed of high-strength materials, such as alloy steel, which provide exceptional resistance to fracture. The design includes a threaded shaft that ensures a tight and secure fit, and the screw head is crafted to distribute force evenly, reducing the risk of stripping or damage. Additionally, the screw may feature a coating that offers corrosion resistance, further extending its lifespan in harsh environments.

Benefits

Using the 2873989 Fracture-Resistant Screw offers several benefits. Its enhanced durability ensures that it can withstand the mechanical stress encountered in heavy-duty truck applications. The screw’s resistance to fracture helps maintain the integrity of critical components, reducing the likelihood of unexpected failures. Furthermore, its longevity in harsh operating conditions means that it requires less frequent replacement, contributing to lower maintenance costs and increased uptime for the vehicle.

Installation Guidelines

Proper installation of the 2873989 Fracture-Resistant Screw is vital to ensure its effectiveness. Begin by cleaning the installation area to remove any debris or corrosion. Use the appropriate torque wrench to install the screw, ensuring it is tightened to the manufacturer’s specified torque settings. This prevents over-tightening, which could damage the screw or the component it is securing. Additionally, consider using a thread locker to enhance the screw’s resistance to vibration.

Troubleshooting Common Issues

Common issues with the 2873989 Fracture-Resistant Screw may include loosening due to vibration or corrosion. If loosening is detected, re-tighten the screw to the specified torque settings and consider applying a thread locker. Corrosion can be addressed by cleaning the affected area and applying a corrosion-resistant coating. Regular inspections can help identify these issues early, allowing for prompt corrective action.

Maintenance Tips

To ensure the optimal performance and longevity of the 2873989 Fracture-Resistant Screw, regular maintenance is recommended. Inspect the screw periodically for signs of wear, corrosion, or loosening. Clean the screw and surrounding area to prevent the buildup of debris and contaminants. If the screw shows signs of damage or excessive wear, replace it to maintain the integrity of the secured components.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of heavy-duty applications. Cummins is known for its commitment to excellence and its focus on providing reliable, high-performance solutions for its customers.

Fracture-Resistant Screw 2873989 Compatibility with Cummins Engines

The Fracture-Resistant Screw part number 2873989, manufactured by Cummins, is designed to fit seamlessly into various Cummins engine models. This screw is engineered to withstand high stress and pressure, ensuring durability and reliability in demanding conditions.

Engine Compatibility

15N CM2380 M104B

This engine model benefits from the robust design of the 2873989 screw, which is crucial for maintaining structural integrity in high-stress environments.

ISZ13 CM2150 Z105, QSZ13 CM2150 Z101, QSZ13 CM2150 Z102

These engines, part of the QSZ13 series, are equipped with the 2873989 screw to ensure that critical components remain securely fastened, even under extreme operational conditions.

Z13 Z108G

The 2873989 screw is integral to the Z13 Z108G engine, providing the necessary strength and resistance to fractures that are vital for the engine’s longevity and performance.

Z14 CM2670 Z103B

In the Z14 CM2670 Z103B engine, the 2873989 screw plays a key role in maintaining the integrity of the engine’s components, ensuring that the engine operates efficiently and reliably over time.

By integrating the 2873989 Fracture-Resistant Screw into these Cummins engine models, users can expect enhanced durability and performance, making it a critical component for maintaining the engine’s operational efficiency.

Role of Part 2873989 Fracture-Resistant Screw in Engine Systems

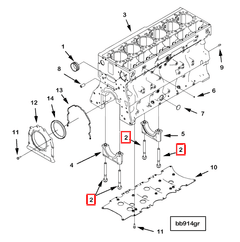

In the intricate assembly of engine systems, the part 2873989 Fracture-Resistant Screw plays a significant role in ensuring the structural integrity and reliable operation of several key components.

Block Assembly

Within the block assembly, the fracture-resistant screw is instrumental in securing various sub-components. It ensures that the block remains a cohesive unit under the immense pressures and vibrations generated during engine operation. This screw is particularly important in maintaining the alignment and stability of the block, which is essential for the efficient transfer of power and the overall durability of the engine.

Cylinder Integration

The cylinders, which are vital for the combustion process, rely on the fracture-resistant screw to maintain their precise positioning within the block. This screw helps in securing the cylinder to the block, ensuring that the combustion chambers are sealed properly. Proper sealing is necessary to prevent leaks and maintain the compression levels required for efficient combustion.

Cylinder Block Stability

In the cylinder block, the fracture-resistant screw contributes to the overall stability of the engine’s core structure. By securing the various components within the cylinder block, it helps in distributing the forces generated during engine operation evenly. This even distribution is key to preventing stress concentrations that could lead to fractures or other forms of mechanical failure.

The fracture-resistant screw’s role in these components underscores its importance in maintaining the engine’s structural integrity and operational efficiency. Its ability to withstand high stresses and resist fractures ensures that the engine can perform reliably under a wide range of operating conditions.

Conclusion

The 2873989 Fracture-Resistant Screw by Cummins is a critical component in the maintenance and operation of heavy-duty trucks. Its design and features ensure durability, reliability, and resistance to fracture, making it essential for securing critical components under demanding conditions. Proper installation, regular maintenance, and prompt troubleshooting of common issues are key to maximizing the performance and longevity of this Cummins part. By integrating this screw into various Cummins engine models, users can expect enhanced engine durability and performance, contributing to the overall efficiency and reliability of heavy-duty truck systems.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.