This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 2874111 Socket Head Cap Screw is a specialized fastener produced by Cummins, a renowned manufacturer in the commercial truck industry. This screw is significant in commercial truck applications due to its robust design and reliable performance, contributing to the overall efficiency and durability of truck components.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for efficient tightening and loosening using a hex key. They are widely used in mechanical and automotive applications for their strength, precision fit, and ease of use. These screws function by providing a secure connection between components, distributing load evenly, and resisting loosening under vibration and dynamic conditions 1.

Purpose of the 2874111 Socket Head Cap Screw in Truck Operations

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in various applications within the truck, such as securing engine components, attaching body panels, and fastening chassis parts. Its design ensures a strong and durable connection, which is vital for the safe and efficient operation of the vehicle.

Key Features

The 2874111 Socket Head Cap Screw features a robust design with a hexagonal socket head that allows for precise installation and removal. It is made from high-quality materials, ensuring durability and resistance to corrosion. The screw’s design includes a fully threaded shank, which provides a strong grip and secure fastening. Additionally, the screw’s surface treatment enhances its performance in demanding environments 2.

Benefits

Using the 2874111 Socket Head Cap Screw offers several advantages. It provides improved fastening efficiency due to its easy installation with a hex key. The screw enhances structural integrity by offering a strong and secure connection between components. Its design also allows for ease of installation and removal, facilitating maintenance and repair processes 3.

Installation Guidelines

Proper installation of the 2874111 Socket Head Cap Screw involves several steps to ensure optimal performance and longevity. Begin by selecting the appropriate size hex key for the screw’s socket. Insert the hex key into the socket and align the screw with the designated hole. Turn the hex key clockwise to tighten the screw, ensuring it is snug but not overtightened to avoid damage. Use a torque wrench if available to achieve the recommended torque specification.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws include loosening due to vibration or corrosion. To troubleshoot, inspect the screw for signs of wear or damage and ensure it is properly tightened. Regular maintenance involves checking the screw’s condition during routine inspections and replacing it if necessary to prevent failure. Applying a thread locker can also help maintain the screw’s position and prevent loosening.

Compatibility and Applications

The 2874111 Socket Head Cap Screw is typically used in various applications within commercial trucks, including engine components, body panels, and chassis parts. It is designed to be compatible with standard threading and socket sizes, ensuring versatility in different truck models and configurations.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. Founded in 1919, Cummins has a long history of producing reliable and high-performance engines and components. The company’s product range includes engines, powertrains, and related technologies, serving a variety of industries. Cummins’ reputation for excellence is built on its dedication to engineering excellence and customer satisfaction.

Socket Head Cap Screw 2874111 in Cummins Engines

The Socket Head Cap Screw 2874111, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the assembly and maintenance of the engines, ensuring secure fastening and structural integrity.

ISX12 Series Engines

The Socket Head Cap Screw 2874111 is utilized in the following ISX12 series engines:

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

These engines benefit from the robust design of the 2874111 screw, which provides reliable fastening in high-stress environments.

ISZ13 Series Engine

The ISZ13 CM2150 Z105 engine also incorporates the Socket Head Cap Screw 2874111. This part ensures the secure attachment of various components, contributing to the engine’s overall performance and durability.

QSX11.9 Series Engine

In the QSX11.9 CM2250 ECF engine, the 2874111 screw is essential for maintaining the integrity of the engine’s structure. Its use in this model highlights its versatility and importance across different engine configurations.

QSZ13 Series Engines

The QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines both utilize the Socket Head Cap Screw 2874111. This part’s application in these engines underscores its reliability and effectiveness in securing various engine components.

Z13 Series Engine

Lastly, the Z13 Z108G engine incorporates the 2874111 screw, ensuring that critical components are fastened securely. This application further demonstrates the part’s importance in maintaining engine stability and performance.

Role of Part 2874111 Socket Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 2874111 Socket Head Cap Screw serves as a fundamental fastening component. Its primary function is to securely hold together various engine components, ensuring the structural integrity and operational efficiency of the system.

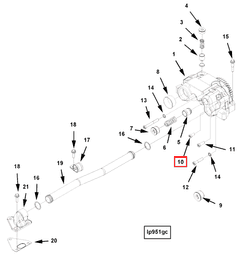

Lubricating Oil Pump

Within the lubricating oil pump, the Socket Head Cap Screw is instrumental in attaching the pump housing to the engine block. This secure attachment is vital for maintaining the pump’s alignment and stability, which in turn ensures consistent oil flow and pressure. The screw’s robust design withstands the dynamic forces and vibrations inherent in engine operation, contributing to the pump’s reliable performance.

Pump Components

In broader pump applications within the engine, the Socket Head Cap Screw is used to fasten pump covers, impellers, and other critical components. Its hex-shaped head allows for precise torque application, minimizing the risk of over-tightening or stripping. This precision is essential for maintaining the pump’s sealing surfaces and preventing leaks, which could lead to a loss of lubrication and increased wear on engine parts.

Lubricating Oil System

Throughout the lubricating oil system, the Socket Head Cap Screw plays a key role in assembling oil filters, pressure relief valves, and bypass valves. By securely fastening these components, it ensures that the oil system operates within specified parameters, providing optimal lubrication to moving parts and enhancing the engine’s longevity and performance.

Conclusion

The 2874111 Socket Head Cap Screw is a vital element in the assembly and functionality of engine systems, particularly within the lubricating oil pump and broader pump components. Its reliable fastening capabilities are essential for maintaining the integrity and efficiency of the engine’s lubrication system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.