This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw, specifically Part #2874112 by Cummins, is a vital component in the realm of commercial trucks. Cummins, a renowned manufacturer in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty applications. This part is integral to the structural integrity and operational efficiency of commercial trucks.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are fasteners characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. In the automotive industry, these screws are widely used due to their strength, precision fit, and ease of installation. They function by providing a secure connection between components, ensuring stability and reliability under various operational conditions 1.

Purpose of the 2874112 Socket Head Cap Screw in Trucks

The 2874112 Socket Head Cap Screw by Cummins serves a specific role in the operation and maintenance of commercial trucks. It is designed to fasten critical components, ensuring they remain securely in place under the rigorous conditions encountered in heavy-duty trucking. This screw contributes to the overall durability and reliability of the truck’s structure and systems 2.

Key Features

The 2874112 Socket Head Cap Screw boasts several distinctive characteristics. Its design includes a hexagonal socket head, which allows for precise and efficient tightening. The screw is crafted from high-quality materials, ensuring it can withstand the stresses and strains of heavy-duty applications. Additionally, its unique attributes enhance performance, providing a reliable fastening solution for commercial trucks.

Benefits

Utilizing the 2874112 Socket Head Cap Screw offers several advantages. Its robust construction contributes to improved durability, making it suitable for long-term use in demanding environments. The screw’s design facilitates ease of installation, reducing the time and effort required during maintenance procedures. Furthermore, its reliability in heavy-duty applications ensures consistent performance, supporting the operational efficiency of commercial trucks.

Installation and Usage

Proper installation of the 2874112 Socket Head Cap Screw involves using the appropriate tools and techniques. A hex key is recommended for tightening the screw to the specified torque, ensuring a secure fit without over-tightening. Careful alignment and gradual tightening are essential to prevent damage to the screw or the components being fastened.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws may include loosening over time or corrosion in harsh environments. Regular inspection and maintenance can help identify and address these issues promptly. Ensuring the screw is properly torqued during installation and applying a suitable anti-corrosion treatment can enhance its longevity and performance.

Safety Considerations

When working with Socket Head Cap Screws, especially in a commercial truck setting, it is important to observe safety practices. This includes using the correct tools to avoid damage to the screw or surrounding components. Additionally, ensuring proper torque specifications are followed helps prevent over-tightening, which can lead to screw failure or component damage.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial vehicle industry, known for its wide range of products, including engines, filtration systems, and aftermarket parts. With a rich history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance components. The company’s commitment to excellence is reflected in its product offerings, which are designed to meet the rigorous demands of commercial applications 3.

Socket Head Cap Screw 2874112 in Cummins Engines

The Socket Head Cap Screw 2874112, manufactured by Cummins, is a critical component in various Cummins engine models. This part is integral to the assembly and maintenance of several engine types, ensuring secure fastening and structural integrity.

ISX12 Series

The ISX12 engines, including the ISX12 CM2350 X102, ISX12 G CM2180 EJ, and ISX12/ISX11.9 CM2250, utilize the Socket Head Cap Screw 2874112 in multiple applications. This screw is essential for fastening components within the engine’s framework, ensuring that parts remain tightly secured during operation.

ISZ13 Series

In the ISZ13 CM2150 Z105 engine, the Socket Head Cap Screw 2874112 is used to fasten various parts, contributing to the engine’s overall stability and performance. This screw’s design allows for precise tightening, which is crucial for maintaining the engine’s operational efficiency.

QSX11.9 Series

The QSX11.9 CM2250 ECF engine also incorporates the Socket Head Cap Screw 2874112 in its construction. This screw is used in areas where high precision and reliability are necessary, ensuring that the engine components are held firmly in place.

QSZ13 Series

For the QSZ13 CM2150 Z101 and QSZ13 CM2150 Z102 engines, the Socket Head Cap Screw 2874112 plays a vital role in securing multiple parts. Its use in these engines highlights its versatility and importance in maintaining the structural integrity of the engine.

Z13 Series

In the Z13 Z108G engine, the Socket Head Cap Screw 2874112 is employed to fasten various components, ensuring that the engine operates smoothly and efficiently. This screw’s design and material make it suitable for the demanding conditions within the engine.

Each of these engines benefits from the Socket Head Cap Screw 2874112, which is designed to provide reliable fastening in high-stress environments. The screw’s compatibility across different engine models underscores its importance in Cummins’ engine assembly and maintenance processes.

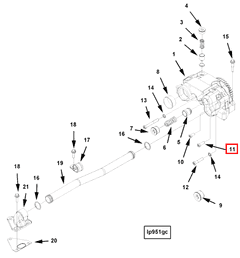

Role of Part 2874112 Socket Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 2874112 Socket Head Cap Screw is instrumental in ensuring the secure fastening of various components. This screw is particularly significant in the context of the lubricating oil pump and the overall lubricating oil system.

Lubricating Oil Pump

Within the lubricating oil pump, the Socket Head Cap Screw (part 2874112) is utilized to fasten critical components such as the pump housing to the engine block. This secure attachment is essential for maintaining the structural integrity of the pump, ensuring it operates efficiently under the dynamic conditions of engine operation. The screw’s design allows for precise torque application, which is vital for the consistent performance of the pump.

Lubricating Oil System

In the broader lubricating oil system, the Socket Head Cap Screw plays a role in securing various fittings and connections. This includes the attachment of oil lines, filters, and sensors. The reliable fastening provided by this screw is fundamental in preventing leaks and ensuring the smooth flow of lubricating oil throughout the engine. Proper sealing and connection are paramount to maintaining optimal lubrication, which in turn protects engine components from wear and damage.

Pump Assembly

During the assembly of the pump, the Socket Head Cap Screw is used to secure the pump cover, ensuring a tight seal that prevents oil leakage. This is particularly important in high-pressure environments where even minor leaks can lead to significant performance issues. The screw’s hex socket head allows for easy and secure tightening, which is essential during both initial assembly and maintenance procedures.

Conclusion

In summary, the part 2874112 Socket Head Cap Screw is a key component in the secure and efficient operation of engine systems, particularly within the lubricating oil pump and the overall lubricating oil system. Its role in fastening and sealing critical components underscores its importance in maintaining engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.