This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

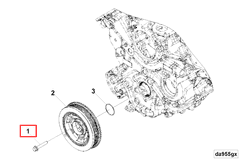

The 2883762 Fracture Resistant Screw by Cummins is a specialized component designed to enhance the durability and reliability of heavy-duty trucks. This screw is integral to maintaining the structural integrity of various truck components under demanding operational conditions. Its role in heavy-duty truck maintenance and operation underscores the importance of using high-quality, durable fasteners in such applications 2.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are engineered to withstand significant stress without breaking. These screws are typically constructed from materials that offer superior tensile strength and resistance to fatigue, such as high-grade steel alloys. The primary function of these screws is to secure components firmly while enduring high loads and dynamic stresses. In high-stress applications, such as those found in heavy-duty trucks, fracture resistance ensures that the screws remain intact, thereby maintaining the safety and efficiency of the vehicle 1.

Purpose of the 2883762 Fracture Resistant Screw

The 2883762 Fracture Resistant Screw is specifically designed to play a crucial role in the operation of heavy-duty trucks. It is utilized in environments where components are subjected to extreme forces and vibrations. This screw is often found in critical applications such as engine mounts, transmission housings, and chassis components, where maintaining a secure connection is vital for the truck’s performance and safety.

Key Features

The 2883762 Fracture Resistant Screw boasts several key features that enhance its performance and durability. Its design incorporates a robust thread profile that ensures a strong grip and resistance to loosening. The material composition typically includes high-tensile steel, which provides exceptional strength and durability. Additionally, the screw may feature a corrosion-resistant coating to protect against environmental factors, ensuring longevity in various operating conditions.

Benefits

Using the 2883762 Fracture Resistant Screw offers several benefits. Its high tensile strength and fracture resistance contribute to improved reliability and longevity, reducing the likelihood of failure under stress. Compared to standard screws, this fracture-resistant variant provides enhanced performance in demanding applications, leading to fewer maintenance issues and increased operational uptime.

Installation Guidelines

Proper installation of the 2883762 Fracture Resistant Screw is vital to ensure optimal performance. The installation process should follow these guidelines:

- Ensure the mating surfaces are clean and free of debris.

- Use the appropriate torque specifications provided by the manufacturer to secure the screw without over-tightening.

- Verify that the screw is properly seated and aligned with the component it is securing.

- Inspect the installation for any signs of damage or misalignment.

Troubleshooting and Maintenance

To maintain the effectiveness of the 2883762 Fracture Resistant Screw, regular inspections are recommended. Look for signs of wear, corrosion, or loosening. If any issues are detected, the screw should be replaced promptly to prevent potential failures. Additionally, ensuring that all components are properly torqued during installation will help maintain the screw’s integrity over time.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to innovation and quality in the automotive industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the rigorous demands of heavy-duty applications. Cummins’ dedication to quality and performance is evident in their fracture-resistant screw offerings, such as the 2883762, which are engineered to provide reliable and durable solutions for heavy-duty trucks 2.

Fracture Resistant Screw 2883762 in Cummins Engines

The Fracture Resistant Screw 2883762, manufactured by Cummins, is a critical component in various engine systems. This screw is designed to enhance the durability and reliability of the engine by resisting fracture under high stress conditions. Its application in Cummins engines ensures that the engine maintains its integrity and performance over extended periods of use.

In the ISV (Intelligent Systems Vehicle) engines by Nissan, the Fracture Resistant Screw 2883762 plays a pivotal role in securing various engine components. This screw is particularly important in areas where the engine is subjected to significant mechanical stress, ensuring that the engine can withstand these forces without compromising its structural integrity.

The use of this screw in Cummins engines is widespread, often found in critical assemblies such as the cylinder head, engine block, and other high-stress areas. Its design and material properties make it an essential part of the engine’s overall reliability and longevity.

By integrating the Fracture Resistant Screw 2883762 into their engine designs, Cummins and Nissan ensure that their engines can operate efficiently and reliably, even under demanding conditions. This screw’s role in maintaining the structural integrity of the engine is vital for the performance and durability of the vehicle.

Role of Part 2883762 Fracture Resistant Screw in Engine Systems

Part 2883762, the Fracture Resistant Screw, is integral to the assembly and secure functioning of various engine components. Its robust design ensures that it can withstand the high stress and vibrations typical in engine operations.

Damper and Vibration Control

In the context of engine dampers, the Fracture Resistant Screw is used to secure the damper to the engine block. This connection is vital for maintaining the damper’s alignment and effectiveness in absorbing vibrations. Proper securing ensures that the damper can efficiently reduce engine vibrations, contributing to smoother operation and reduced wear on other components.

Front Crankshaft Seal Kit

When assembling the front crankshaft seal kit, the Fracture Resistant Screw plays a key role in attaching the seal to the engine block. This secure attachment is essential for maintaining the seal’s integrity, preventing oil leaks, and ensuring that the crankshaft operates within its designed parameters. The screw’s resistance to fracture under stress is particularly important in this application, given the dynamic forces at play.

Hardware Kit

Within a hardware kit, the Fracture Resistant Screw is often used for various fastening applications. Whether securing brackets, mounts, or other hardware components, its durability ensures that these parts remain firmly in place despite the engine’s operational stresses. This reliability is essential for the overall structural integrity of the engine assembly.

Long Block Kit

In a long block kit, which includes the engine block, crankshaft, pistons, and other core components, the Fracture Resistant Screw is employed to secure critical attachments. This might include fastening the timing cover, attaching sensor brackets, or securing other ancillary components. The screw’s fracture resistance ensures that these attachments remain secure throughout the engine’s lifespan, contributing to consistent performance.

Upper Engine Gasket Kit

The upper engine gasket kit often requires secure fastening of components such as the intake manifold, valve cover, and other upper engine parts. The Fracture Resistant Screw is used to ensure these components are tightly and reliably attached. This secure fastening is vital for maintaining proper sealing and preventing leaks, which can adversely affect engine performance and efficiency.

Overall, the Fracture Resistant Screw (Part 2883762) is a fundamental component in ensuring the secure and reliable assembly of various engine systems. Its application across different engine components underscores its importance in maintaining the integrity and performance of the engine.

Conclusion

The 2883762 Fracture Resistant Screw by Cummins is a critical component in the maintenance and operation of heavy-duty trucks and engines. Its robust design, high tensile strength, and resistance to fracture make it an essential part in securing various engine components under demanding conditions. Proper installation and regular maintenance of this screw ensure the longevity and reliability of the engine, contributing to the overall performance and safety of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.