This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

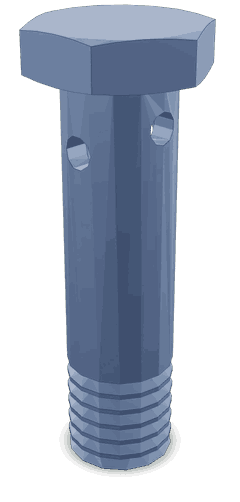

The 2891479 Banjo Connector Screw, manufactured by Cummins, is a critical component in commercial truck operations. Cummins, a renowned name in the industry, produces a range of parts designed to enhance the efficiency and reliability of truck systems. This Cummins part plays a role in the hydraulic and fuel systems of trucks.

Basic Concepts and Functionality

A Banjo Connector Screw is a fitting used to connect hoses or pipes in hydraulic and fuel systems. Its design includes a bolt with a banjo fitting at one end, typically sealed with gaskets. This fitting allows for the transfer of fluids under pressure, ensuring a secure and leak-free connection.

Purpose of the 2891479

The 2891479 serves to connect various components within a truck’s hydraulic or fuel system. It facilitates the transfer of fluids, such as hydraulic fluid or fuel, between different parts of the system. Its application ensures that the system operates efficiently, with minimal risk of leaks or disruptions in fluid flow.

Key Features

The 2891479 is characterized by several key features. It is made from durable materials to withstand the pressures and conditions within a truck’s system. The thread type is designed for a secure fit, and the connection design allows for easy installation and removal. Additionally, the fitting is equipped with gaskets to prevent leaks.

Benefits

Using the 2891479 offers several advantages. Its durable construction ensures longevity, even under demanding conditions. The design of the fitting helps prevent leaks, maintaining system integrity. Furthermore, the fitting is easy to install, reducing downtime during maintenance or repairs.

Installation Process

Installing the 2891479 requires careful attention to detail. Begin by ensuring the mating surfaces are clean and free of debris. Apply the appropriate gasket to the fitting, then thread the screw into the designated port. Use a torque wrench to tighten the fitting to the manufacturer’s specified torque, ensuring a secure connection without over-tightening.

Common Issues and Troubleshooting

Common issues with Banjo Connector Screws include leaks and corrosion. Leaks may occur due to improper installation, damaged gaskets, or system pressure exceeding the fitting’s rating. Corrosion can result from exposure to moisture or incompatible fluids. Troubleshooting involves inspecting the fitting and gaskets for damage, ensuring proper installation, and addressing any corrosion with appropriate treatments.

Maintenance Tips

To ensure the longevity and reliable performance of the 2891479, regular maintenance is recommended. Inspect the fitting and gaskets for signs of wear or damage during routine checks. Replace gaskets as needed to prevent leaks. Additionally, ensure that the fitting is tightened to the correct torque during installation to avoid over-tightening or under-tightening.

Safety Considerations

When working with Banjo Connector Screws, it is important to follow safety practices. Ensure that the system is depressurized before beginning any work to avoid injury from pressurized fluid. Use the correct tools and follow torque specifications to prevent damage to the fitting or system. Additionally, be aware of the system’s pressure ratings and ensure the fitting is suitable for the application.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company offers a wide range of products designed to meet the needs of various applications, from on-highway to off-highway and industrial uses.

Integration of Part 2891479 in Cummins Engines

The 2891479 is a critical component in the fluid management systems of various Cummins engines. This part is integral to ensuring the secure connection of hoses to the engine’s fuel, oil, or coolant systems, preventing leaks and maintaining system integrity.

QSK60 Engine

In the QSK60 engine, the 2891479 is used in the fuel and coolant systems. Its design ensures a tight seal, which is crucial for the high-pressure environments these systems operate in. The screw’s robust construction allows it to withstand the rigors of continuous operation, contributing to the engine’s overall reliability and performance.

CM850 Engine

For the CM850 engine, the 2891479 is employed in both the fuel and lubrication systems. Given the CM850’s use in heavy-duty applications, the screw’s ability to maintain a secure connection under varying operational conditions is vital. This ensures that the engine’s lubrication system operates efficiently, reducing wear and extending the engine’s lifespan.

MCRS Engine

In the MCRS engine, the 2891479 is utilized in the coolant system. The MCRS engine is designed for marine applications, where the screw’s resistance to corrosion and ability to maintain a tight seal in a marine environment are essential. This ensures that the engine’s cooling system functions effectively, preventing overheating and maintaining optimal performance in challenging conditions.

Grouping Considerations

When considering the integration of the 2891479 in these engines, it is important to note the commonality in its application across different systems within each engine type. The screw’s design and material are tailored to meet the specific demands of each system, whether it be the high-pressure fuel system, the lubrication system, or the coolant system. This ensures that the screw performs reliably in its designated role, contributing to the overall efficiency and longevity of the engine.

Role of Part 2891479 in Engine Systems

The 2891479 is an essential component in various engine systems, facilitating secure and efficient fluid transfer. Its application spans across several key areas within the engine, each benefiting from the precise functionality this part offers.

Fuel Drain Plumbing

In fuel drain systems, the 2891479 ensures a tight and reliable connection between the fuel lines and the drain valve. This connection is vital for the safe and efficient removal of fuel from the system during maintenance or emergency situations. The screw’s design allows for easy disassembly and reassembly, which is particularly beneficial during routine checks or when addressing fuel system issues.

Crankcase Breather System

Within the crankcase breather system, the 2891479 is used to connect the breather hose to the crankcase. This connection is important for maintaining the integrity of the crankcase ventilation system. By allowing pressurized gases to escape while preventing the ingress of contaminants, the screw helps in preserving the engine’s performance and longevity. Its secure fitting ensures that the breather system operates efficiently, reducing the risk of oil contamination and ensuring optimal engine function.

Arrangement of Fluid Lines

The 2891479 is also instrumental in the arrangement of various fluid lines within the engine compartment. Whether connecting oil lines, coolant passages, or other fluid pathways, this component ensures that each connection is leak-proof and maintains the specified pressure within the system. This is particularly important in high-pressure systems where even a minor leak can lead to significant performance issues or safety hazards.

Conclusion

The 2891479 Banjo Connector Screw is a versatile and reliable component that enhances the functionality and safety of engine systems. Its applications in fuel drain plumbing, crankcase breather systems, and the arrangement of fluid lines underscore its importance in maintaining the overall efficiency and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.