3094188

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3094188 Banjo Bolt Connector, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts and systems that contribute to the efficiency and reliability of heavy-duty trucks. This Cummins part is significant in maintaining the integrity of fluid transfer systems within these vehicles.

Basic Concepts of Banjo Bolt Connectors

A Banjo Bolt Connector is a type of fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with an integrated fitting that allows for the secure attachment of hoses. The connector operates by providing a sealed passage for fluid flow, ensuring that systems like hydraulic or fuel lines function correctly. The design allows for easy connection and disconnection, which is beneficial during maintenance or repairs 1.

Purpose of the 3094188 Banjo Bolt Connector

The 3094188 Banjo Bolt Connector plays a role in the operation of a truck by facilitating the transfer of fluids within hydraulic or fuel systems. It ensures a secure and leak-free connection between components, which is vital for the efficient operation of these systems. By maintaining a consistent fluid flow, the connector contributes to the overall performance and reliability of the truck 2.

Key Features

The 3094188 Banjo Bolt Connector is designed with specific elements that enhance its performance and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring longevity in demanding environments. The connector features a precise fitting that provides a reliable seal, minimizing the risk of leaks. Additionally, its design allows for straightforward installation, reducing the time and effort required during maintenance procedures 3.

Benefits

The 3094188 Banjo Bolt Connector offers several advantages. Its robust construction and materials contribute to improved sealing, which is crucial for maintaining the integrity of fluid systems. The ease of installation not only saves time but also reduces the potential for errors during maintenance. Furthermore, the connector’s resistance to corrosion ensures that it remains functional even in harsh operating conditions.

Installation Process

To install the 3094188 Banjo Bolt Connector, begin by ensuring that the connection points are clean and free of debris. Apply a compatible sealant to the threads of the bolt to enhance the seal. Carefully align the connector with the hose or pipe and tighten the bolt to the manufacturer’s specified torque settings. It is important to avoid over-tightening, which could damage the fitting or the connected components. Once installed, check for any signs of leaks to confirm a secure connection.

Common Issues and Troubleshooting

Typical problems with Banjo Bolt Connectors may include leaks, corrosion, or difficulty in installation or removal. If a leak is detected, the connector should be inspected for proper seating and the presence of sealant. Corrosion can be addressed by replacing the affected parts and ensuring that compatible materials are used to prevent future issues. Difficulty in installation or removal may be due to improper torque settings or the presence of debris, which should be cleaned away before reattempting the process.

Maintenance Tips

Regular maintenance of the 3094188 Banjo Bolt Connector is important to ensure its reliable operation. Inspect the connector periodically for signs of wear or corrosion. Clean the connection points to remove any buildup that could affect performance. If the connector is part of a system that undergoes frequent cycling, consider more regular checks to catch potential issues early. Applying a fresh layer of sealant during maintenance can also help maintain a secure seal.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance parts. The company’s product range includes engines, powertrain components, and aftermarket parts, all of which are designed to meet the demanding requirements of heavy-duty applications.

Compatibility of Banjo Bolt Connector Part 3094188 with Cummins Engines

The Banjo Bolt Connector part 3094188, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part is crucial for ensuring a secure and leak-proof connection in hydraulic and fuel systems, which is essential for the proper functioning of the engines.

K50 Engines

The K50 engine series benefits from the use of the Banjo Bolt Connector part 3094188. This part is engineered to fit the specific design and requirements of the K50 engines, ensuring compatibility and reliability in various applications.

QST30 CM2350 T101 and QST30 CM552 Engines

The QST30 CM2350 T101 and QST30 CM552 engines also utilize the Banjo Bolt Connector part 3094188. These engines, part of the QST30 series, are designed for heavy-duty applications, and the connector part plays a vital role in maintaining the integrity of the hydraulic and fuel lines. The part’s design ensures it fits perfectly with the specifications of these engines, providing a robust connection that can withstand the rigors of demanding environments.

By using the Banjo Bolt Connector part 3094188, these engines can maintain optimal performance and reliability, ensuring that the connections remain secure and leak-free under various operating conditions.

Role of Part 3094188 Banjo Bolt Connector in Engine Systems

The 3094188 Banjo Bolt Connector is integral to several engine systems, ensuring secure and efficient fluid transfer. Here’s how it interfaces with various components:

Fuel Systems

In the Fuel Line Kit, the Banjo Bolt Connector is used to join fuel lines to injectors or other fuel system components. This ensures a leak-free connection, maintaining consistent fuel pressure and flow.

Electrical Valve Systems

For the 12V Valve/Electric Kit and 24V Valve/Electric Kit, the Banjo Bolt Connector facilitates the connection between hydraulic lines and solenoid valves. This is essential for precise control of fuel or oil flow in response to electrical signals.

High-Horsepower Systems

In the HHP 12V VLV/ELEC Kit and HHP 24V VLV/ELEC Kit, the Banjo Bolt Connector plays a role in connecting high-pressure lines to electronic control valves. This ensures that the high-horsepower engine receives the necessary fluid dynamics for optimal performance.

Oil Control Systems

Within the Oil Control Valve Repair Kit, the Banjo Bolt Connector is used to re-establish connections in the oil control system. This is vital for maintaining proper lubrication and cooling within the engine.

Specialized Kits

For the QST30 Centinel Kit and QST30 Fuel Fill-Up Kit, the Banjo Bolt Connector ensures secure connections in specialized fuel systems, enhancing the reliability and safety of fuel delivery.

Multiple Key-Off Kit

In the Multiple Key-Off Kit, the Banjo Bolt Connector is employed to connect hydraulic lines that manage the key-off functions, ensuring that the engine’s systems are properly deactivated when not in use.

Plumbing and Fuel Drain Systems

In Plumbing and Fuel Drain Systems, the Banjo Bolt Connector is used to connect various lines, ensuring that fuel and other fluids are efficiently routed and drained as needed.

Oil Replenishing System

Finally, in the Oil Replenishing System, the Banjo Bolt Connector is crucial for connecting lines that supply additional oil to the engine, maintaining lubrication under varying operational conditions.

Conclusion

The 3094188 Banjo Bolt Connector is a critical component in the maintenance and operation of Cummins engines, particularly in commercial truck applications. Its robust design, ease of installation, and resistance to corrosion make it a reliable choice for ensuring secure and leak-free connections in hydraulic and fuel systems. Regular maintenance and proper installation are key to maximizing the performance and longevity of this Cummins part.

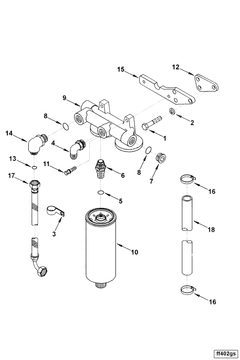

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.