This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3163535 Self Tapping Metal Screw is a specialized fastener designed for use in commercial trucks. Its purpose is to provide a secure and reliable connection between metal components, facilitating both the assembly and maintenance of truck parts. This screw is particularly valued in the trucking industry for its efficiency and durability.

Basic Concepts of Self Tapping Metal Screws

Self tapping metal screws are designed to cut their own threads into metal as they are driven in, eliminating the need for pre-tapped holes. This feature makes them highly versatile and efficient for various applications across different industries, including automotive, construction, and manufacturing. They are commonly used where speed and ease of installation are crucial, and where the integrity of the fastening is paramount 1.

Purpose and Application in Commercial Trucks

In commercial trucks, the Cummins 3163535 Self Tapping Metal Screw plays a significant role in both the assembly and maintenance of various components. It is often used in areas where quick and secure fastening is required, such as in the attachment of body panels, engine components, and other structural parts. Its application helps ensure that parts remain securely fastened under the demanding conditions encountered in commercial trucking 2.

Key Features

The Cummins 3163535 Self Tapping Metal Screw is characterized by several key features that enhance its performance. It is typically made from high-strength steel, ensuring durability and resistance to wear. The thread design is optimized for cutting into metal efficiently while providing a strong hold. Additionally, the screw may feature a coating or treatment to resist corrosion, extending its lifespan in harsh environments 3.

Benefits

Using the Cummins 3163535 Self Tapping Metal Screw offers several advantages. Its design allows for quick and easy installation without the need for pre-drilled holes, saving time during both initial assembly and maintenance procedures. The screw’s durability and resistance to corrosion ensure long-lasting performance, reducing the need for frequent replacements. Furthermore, its secure fastening capability contributes to the overall safety and reliability of the truck.

Installation Process

Proper installation of the Cummins 3163535 Self Tapping Metal Screw involves several steps to ensure optimal performance and longevity. First, identify the location where the screw will be installed. Use a drill to create a pilot hole if necessary, though this step may be omitted due to the screw’s self-tapping nature. Align the screw with the hole and use a screwdriver or drill to drive it in until the desired depth is achieved. Ensure the screw is flush with the surface to avoid any protrusions that could cause damage or injury.

Troubleshooting and Maintenance

Common issues with self tapping metal screws include stripping or breaking during installation, which can be mitigated by using the correct size drill bit for pilot holes and ensuring the screw is driven in at the correct angle. Regular inspection of screws for signs of wear or corrosion is recommended to maintain the integrity of the fastening. In cases where a screw becomes loose, it should be replaced to ensure continued reliable performance.

Safety Considerations

When installing or working with self tapping metal screws, it is important to follow safety practices to prevent injuries and ensure proper functionality. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against flying debris or accidental contact with the screw. Use the correct tools for installation to avoid damaging the screw or the surrounding material. Additionally, ensure that all screws are securely fastened to prevent accidents during operation.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s parts, including the 3163535 Self Tapping Metal Screw, are trusted by professionals for their performance, durability, and contribution to the efficiency and safety of commercial vehicles.

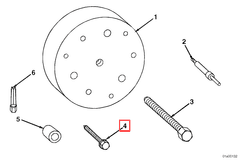

Role of Part 3163535 Self Tapping Metal Screw in Component Systems

The part 3163535 self tapping metal screw is instrumental in the secure and efficient assembly of various engine components. When integrating with a wear sleeve, this screw ensures a tight and durable connection, which is essential for maintaining the integrity of the wear sleeve under operational stress. Its self-tapping feature allows for quick and reliable installation, reducing assembly time and enhancing overall efficiency.

In the context of a seal installation/removal kit, the self tapping metal screw plays a significant role in securing seals in place during installation. This ensures that seals are properly positioned and maintained, which is vital for preventing leaks and maintaining system pressure. The screw’s design allows it to tap into metal surfaces without the need for pre-drilling, simplifying the installation process and ensuring a secure fit.

Furthermore, the self tapping capability of the screw is beneficial during the removal process. It allows for easy extraction without damaging the surrounding components, facilitating a smooth and efficient disassembly. This is particularly important in maintenance scenarios where repeated installations and removals are common.

Overall, the part 3163535 self tapping metal screw enhances the reliability and efficiency of engine component assemblies, ensuring that wear sleeves and seals are securely fastened and easily manageable during both installation and removal processes.

Conclusion

The Cummins 3163535 Self Tapping Metal Screw is a critical component in the assembly and maintenance of commercial trucks. Its design and features provide a secure, durable, and efficient fastening solution that contributes to the overall safety and reliability of the vehicle. Proper installation, maintenance, and safety practices are essential to maximize the benefits of this part.

-

Robinson, A., & Livesey, A. (2006). The Repair of Vehicle Bodies Fifth Edition. Elsevier.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.