3171713

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw Assembly, identified by part number 3171713, is a component manufactured by Cummins. This part is integral to the structural integrity and operational efficiency of commercial trucks. Cummins, a well-established name in the automotive industry, is recognized for its commitment to quality and innovation in manufacturing truck components 1.

Basic Concepts

The Hexagon Flange Head Cap Screw Assembly is designed with specific principles in mind to ensure optimal performance in heavy-duty applications. Its design incorporates a hexagonal flange head, which provides a larger surface area for torque application, reducing the risk of stripping during installation 2. The screw’s function is to securely fasten components together, ensuring they remain in place under significant stress and vibration, common in heavy-duty truck operations. Its application spans various truck components, from engine mounts to chassis assemblies, where reliable fastening is paramount.

Purpose and Role in Truck Operation

The 3171713 Hexagon Flange Head Cap Screw Assembly serves a specific purpose within the truck’s operational framework. It is utilized to fasten critical components that are subject to high stress and dynamic loads. By providing a secure and stable connection, this screw assembly contributes to the overall durability and reliability of the truck. Its role is particularly significant in maintaining the alignment and integrity of components that are vital to the truck’s performance and safety 3.

Key Features

Several key features define the Hexagon Flange Head Cap Screw Assembly. The hexagonal flange head design allows for efficient torque application, minimizing the risk of damage to the screw or the components being fastened. The material composition, typically a high-strength alloy, ensures durability under heavy-duty conditions. Additionally, the threading specifications are designed to provide a strong, secure fit that resists loosening over time, even under vibration and dynamic loads 4.

Benefits

The benefits of using the Hexagon Flange Head Cap Screw Assembly include enhanced fastening security, resistance to loosening, and durability. The design of the screw, with its hexagonal flange head, allows for greater torque application without stripping, ensuring a secure fit. Its material and threading specifications contribute to its resistance to loosening, maintaining a stable connection under dynamic conditions. Furthermore, the durability of the screw assembly ensures long-term performance, reducing the need for frequent replacements.

Installation and Usage

Proper installation and usage of the Hexagon Flange Head Cap Screw Assembly are critical to its performance and longevity. Guidelines recommend using the appropriate torque specifications to ensure a secure fit without over-tightening, which could lead to damage. It is also advisable to use the correct tools for installation to avoid stripping the screw or damaging the components being fastened. Regular inspection and maintenance can help identify any signs of wear or loosening, ensuring the screw assembly continues to perform effectively.

Troubleshooting and Maintenance

Common issues with the Hexagon Flange Head Cap Screw Assembly may include loosening over time or damage due to over-tightening. Troubleshooting these issues involves checking for proper torque application and ensuring the screw and components are free from corrosion or damage. Maintenance practices include regular inspection for signs of wear or loosening and reapplying torque as necessary. Additionally, protecting the screw assembly from environmental factors that could lead to corrosion can help ensure its longevity and performance.

Safety Considerations

When working with the Hexagon Flange Head Cap Screw Assembly, several safety considerations should be observed. Proper handling of the screw and components is necessary to avoid injury. Adherence to torque specifications is crucial to prevent damage to the screw or the components being fastened. Personal protective equipment (PPE), such as gloves and safety glasses, should be worn to protect against potential injuries from sharp edges or flying debris during installation or maintenance procedures.

Cummins Overview

Cummins Inc. is a leader in the automotive industry, known for its history of innovation and commitment to quality in manufacturing truck components. The company’s reputation is built on its dedication to producing reliable, high-performance parts that meet the demanding requirements of commercial and heavy-duty truck applications. Cummins’ focus on quality and innovation ensures that its components, like the Hexagon Flange Head Cap Screw Assembly, contribute to the efficiency, durability, and safety of trucks in operation.

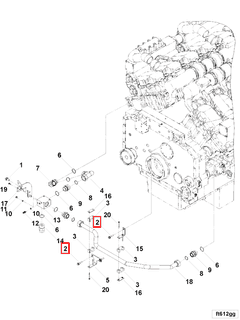

Hexagon Flange Head Cap Screw Assembly (Part 3171713) in Cummins Engines

The Hexagon Flange Head Cap Screw Assembly, identified as part number 3171713, is a critical component in various Cummins engines. This assembly is designed to secure different parts of the engine, ensuring structural integrity and operational efficiency. Here is how it fits into specific Cummins engines:

CM2350 Series

- B4.5 CM2350 B129B

- B6.7 CM2350 B135B

- F3.8 CM2350 F120B

- ISB4.5 CM2350 B104

The CM2350 series engines utilize the Hexagon Flange Head Cap Screw Assembly to secure various components, including cylinder heads and other critical engine parts. This ensures that the engine maintains its structural integrity under high-stress conditions.

CM2620 Series

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

In the CM2620 series, the Hexagon Flange Head Cap Screw Assembly is used to fasten components that are subjected to significant mechanical stress. This includes securing the cylinder heads and other critical engine parts, ensuring that the engine operates smoothly and efficiently.

CM2380 and CM2670 Series

- 15N CM2380 M104B

- B5.6 CM2670 B152B

- B6.7 CM2670 B153B

These engines also rely on the Hexagon Flange Head Cap Screw Assembly to secure various engine components. The assembly’s design allows it to withstand the high pressures and temperatures within the engine, ensuring that the engine remains secure and operational.

CM2150 and CM2880 Series

- ISB/ISD4.5 CM2150 B119

- ISB5.9 CM2880 B140

- ISB5.9 CM2880 B149

The Hexagon Flange Head Cap Screw Assembly is used in these engines to secure components such as the cylinder heads and other critical parts. This ensures that the engine maintains its structural integrity and operates efficiently.

ISBE and ISX Series

- ISBE CM2150

- ISBE4 CM850

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

In the ISBE and ISX series engines, the Hexagon Flange Head Cap Screw Assembly is used to secure various engine components, including the cylinder heads and other critical parts. This ensures that the engine maintains its structural integrity and operates efficiently.

QSB and QSK Series

- QSB3.3 CM2250 EC

- QSB6.7 M CM2250

- QSK19 CM2350 K105

- QSK19 CM2350 K114

- QSK45 CM500

- QSK60 CM500

The Hexagon Flange Head Cap Screw Assembly is used in these engines to secure various components, including the cylinder heads and other critical parts. This ensures that the engine maintains its structural integrity and operates efficiently.

QSK19 CM850 MCRS

In this engine, the Hexagon Flange Head Cap Screw Assembly is used to secure critical components, ensuring that the engine maintains its structural integrity and operates efficiently.

Role of Part 3171713 Hexagon Flange Head Cap Screw Assembly in Engine Systems

The Part 3171713 Hexagon Flange Head Cap Screw Assembly is integral in securing and maintaining the integrity of various engine components. Its applications span across multiple systems, ensuring robust connections and efficient operation.

Breather and Crankcase Systems

In breather and crankcase systems, the Hexagon Flange Head Cap Screw Assembly is used to secure breather covers and crankcase components. This ensures that the breather system functions correctly by allowing pressure release without oil leakage, while the crankcase remains sealed to maintain optimal engine performance.

Air and Fuel Systems

For air and fuel systems, this screw assembly plays a key role in fastening air filters, fuel filters, and lubricating oil filter heads. It ensures these components are securely attached, preventing air or fuel leaks that could affect engine efficiency and performance.

Connection and Plumbing Systems

In connection and plumbing systems, such as aftercooler water, fuel drain, and fuel supply lines, the Hexagon Flange Head Cap Screw Assembly is employed to create tight seals. This is essential for maintaining the integrity of fluid transfer within the engine, ensuring consistent fuel delivery and cooling system performance.

Exhaust and Cover Systems

The assembly is also vital in securing exhaust outlets and engine covers. By providing a strong, vibration-resistant connection, it helps maintain the structural integrity of the exhaust system and protects internal components from external elements.

Drive and Accessory Systems

In drive systems, particularly those involving the front gear train accessory drive and fan drive, the Hexagon Flange Head Cap Screw Assembly ensures that components like dampers and vibration drives are firmly attached. This is important for smooth operation and reducing wear on moving parts.

Electronic and Control Systems

For electronic control module wiring harnesses and engine control modules, this screw assembly secures wiring and modules in place. This ensures reliable electrical connections, which are essential for the proper functioning of engine control systems.

Lubrication and Cooling Systems

In lubrication systems, the assembly is used to attach the lubricating oil filter head, ensuring that oil flows correctly through the filter. In auxiliary cooling systems, it secures components like the heat exchanger, contributing to effective heat management within the engine.

Mounting and Structural Systems

Finally, the Hexagon Flange Head Cap Screw Assembly is utilized in mounting systems, such as lifting brackets and expansion tanks. This ensures that these structural components are securely fastened, providing stability and support for the engine and its ancillary systems.

Conclusion

The Hexagon Flange Head Cap Screw Assembly (part number 3171713) is a critical component in the operation and maintenance of Cummins engines and commercial trucks. Its design, featuring a hexagonal flange head, ensures efficient torque application and secure fastening of critical components under high-stress conditions. The assembly’s high-strength alloy composition and precise threading specifications contribute to its durability and resistance to loosening, making it essential for the structural integrity and operational efficiency of heavy-duty vehicles. Proper installation, regular maintenance, and adherence to safety guidelines are crucial for maximizing the performance and longevity of this Cummins part.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Michael Hilgers, Chassis and Axles (Springer Vieweg, 2023).

↩ -

Hua Zhao, Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines (CRC Press, 2010).

↩ -

Bruce Maclaurin, High Speed Off-Road Vehicles (Wiley, 2018).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.