This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

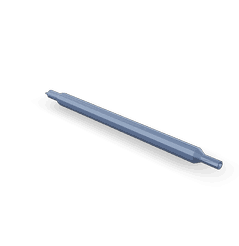

The Screwdriver, Trim Pot Adjustment (Part #3376613) manufactured by Cummins is a specialized tool designed for precise adjustments of trim potentiometers in electronic systems. In the realm of commercial truck maintenance and operation, this Cummins part holds significance due to its role in ensuring the optimal performance of electronic components within the truck’s systems.

Basic Concepts

A trim potentiometer, often referred to as a trim pot, is a variable resistor used to fine-tune electronic circuits. It allows for minor adjustments to the circuit’s resistance, which can affect the operation of various electronic components. The Screwdriver, Trim Pot Adjustment is specifically designed to interact with these trim potentiometers. By turning the screwdriver, technicians can make precise adjustments to the trim pot, thereby modifying the circuit’s characteristics to meet specific operational requirements 1.

Purpose and Role in Truck Operation

This part plays a role in the operation of commercial trucks by enabling fine-tuning of electronic components and systems. This tool is used to make subtle changes to the electronic circuits, which can impact the performance and efficiency of the truck’s systems. By allowing for precise adjustments, it ensures that the electronic components operate within their optimal parameters, contributing to the overall reliability and performance of the truck 2.

Key Features

The Screwdriver, Trim Pot Adjustment is characterized by several key features that enhance its functionality. Its design is ergonomic, allowing for comfortable and precise adjustments. The tool is constructed from durable materials to withstand the rigors of frequent use in a commercial truck maintenance environment. Additionally, it features a calibrated adjustment mechanism that ensures accuracy in making fine-tuned changes to the trim potentiometer 3.

Benefits

Utilizing the Screwdriver, Trim Pot Adjustment in truck maintenance offers several benefits. It provides improved precision in adjustments, allowing for more accurate tuning of electronic components. The ease of use of the tool simplifies the adjustment process, reducing the time required for maintenance tasks. Furthermore, proper tuning of electronic components can lead to enhanced longevity and performance, contributing to the overall efficiency and reliability of the truck 4.

Troubleshooting and Maintenance

When encountering issues related to trim potentiometer adjustments in trucks, it is important to follow a systematic approach to troubleshooting. This may involve checking for physical damage to the trim pot, ensuring proper connections, and verifying the accuracy of the adjustments made. Regular maintenance of the Screwdriver, Trim Pot Adjustment, such as cleaning and inspecting for wear, can help ensure its continued effectiveness and longevity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed with a commitment to quality and innovation. Cummins’ dedication to excellence in truck components is evident in their offerings, including the Screwdriver, Trim Pot Adjustment, which exemplifies their focus on precision and reliability in commercial truck maintenance.

Conclusion

The Screwdriver, Trim Pot Adjustment (Part #3376613) by Cummins is a vital tool in the maintenance and operation of commercial trucks. Its precise adjustment capabilities ensure the optimal performance of electronic components, contributing to the truck’s overall efficiency and reliability. Regular maintenance and proper use of this part are essential for its continued effectiveness in truck maintenance.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Ling, F. F. (2011). The Automotive Body. Springer Science.

↩ -

Ferrari, A., & Pizzo, P. (2022). Injection Technologies: Mixture Formation Strategies. SAE International.

↩ -

Hilgers, M. (2023). Electrical Systems and Mechatronics, Second Edition. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.