Minimum Quantity 6

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw is a fundamental component in the realm of commercial trucks, providing reliable fastening solutions that contribute to the structural integrity and operational efficiency of these vehicles. Manufactured by Cummins, a leader in the automotive industry, the Socket Head Cap Screw part number 3424432 is specifically designed for heavy-duty truck applications. This part plays a significant role in the assembly and maintenance of commercial trucks, ensuring secure and durable connections in various truck components 1.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is a type of fastener characterized by a cylindrical head with a hex socket that allows for easy installation and removal using a hex key. These screws are commonly used in applications requiring high torque and precision fastening. They are typically made from materials such as alloy steel, stainless steel, or titanium, each offering distinct properties like strength, corrosion resistance, and durability 2. The design of the Socket Head Cap Screw ensures a snug fit and reduces the risk of cam-out during tightening, making it a preferred choice for critical applications.

Purpose of the 3424432 Socket Head Cap Screw in Truck Operations

The 3424432 Socket Head Cap Screw by Cummins is integral to the assembly and maintenance of commercial trucks. It is utilized in various applications where secure and durable fastening is required. This screw is often found in engine components, chassis assemblies, and other critical areas where it helps maintain structural integrity and operational efficiency. Its design and material properties ensure it can withstand the rigors of heavy-duty truck operations, providing reliable performance over time 3.

Key Features of the 3424432 Socket Head Cap Screw

The 3424432 Socket Head Cap Screw features a hex socket design, which facilitates easy installation and removal using a hex key. This design reduces the likelihood of damage to the screw head during use. Additionally, the screw is crafted from high-quality materials, ensuring it can endure the demanding conditions of heavy-duty truck applications. Its cylindrical head allows for a countersunk installation, providing a flush surface that enhances the aesthetic and functional aspects of the assembly.

Benefits of Using Socket Head Cap Screws

Socket Head Cap Screws offer several advantages in fastening applications. Their increased torque capacity allows for secure connections in high-stress areas. The reduced cam-out during tightening ensures precise and reliable fastening. Additionally, the ability to be countersunk provides a flush surface, which is beneficial for both aesthetic and functional purposes. These screws are also known for their durability and resistance to corrosion, making them suitable for long-term use in various environments.

Installation and Usage Guidelines

Proper installation of the 3424432 Socket Head Cap Screw involves several steps to ensure optimal performance. Begin by selecting the appropriate hex key for the screw size. Insert the hex key into the socket and align the screw with the designated hole. Apply steady torque to tighten the screw, ensuring it is secure without over-tightening, which could damage the screw or the surrounding material. Torque specifications should be followed to achieve the correct tension. Recommended tools include a torque wrench for precise tightening and a magnetic hex key to prevent the screw from dropping during installation.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws include loosening over time due to vibration or thermal expansion. To troubleshoot, check for proper torque during installation and ensure the screw is compatible with the application. Regular maintenance involves inspecting the screws for signs of wear or corrosion and tightening them as necessary. Replacing screws that show significant wear or damage will help maintain the integrity of the assembly.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality, innovation, and customer satisfaction. The company’s product range includes engines for on-highway and off-highway applications, as well as filtration and power generation systems. Cummins’ dedication to excellence is evident in their rigorous testing and quality control processes, ensuring that their products meet the highest standards of performance and reliability.

Socket Head Cap Screw (Part 3424432) in Cummins Engines

The Socket Head Cap Screw, part number 3424432, is a critical component in various Cummins engines, ensuring secure fastening and structural integrity. This part is integral to the assembly and maintenance of several engine models, providing a reliable connection between different parts.

QSK45 CM500 and QSK60 CM500

In the QSK45 CM500 and QSK60 CM500 engines, the Socket Head Cap Screw is used in multiple applications to maintain the alignment and stability of engine components. These engines, known for their robust design and performance, rely on this screw to secure various parts, ensuring the engine operates smoothly and efficiently.

QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine also utilizes the Socket Head Cap Screw in its construction. This engine, designed for heavy-duty applications, requires reliable fastening solutions to withstand the rigors of demanding environments. The screw’s precision and strength make it an ideal choice for securing critical engine components.

QSK60G, QSV81G, QSV91G, QSW/QSV82, QSW27, and QSW36

The Socket Head Cap Screw is also a key component in the QSK60G, QSV81G, QSV91G, QSW/QSV82, QSW27, and QSW36 engines. These engines, part of Cummins’ diverse lineup, benefit from the screw’s ability to provide a secure and stable connection. Whether used in the assembly of engine blocks, cylinder heads, or other critical parts, this screw ensures that the engine maintains its structural integrity and performance.

Each of these engines, while differing in specifications and applications, shares a common reliance on the Socket Head Cap Screw for its operational efficiency and durability. The screw’s role in these engines underscores its importance in the overall design and functionality of Cummins’ engine products.

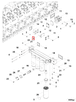

Role of Part 3424432 Socket Head Cap Screw in Engine Systems

The part 3424432 Socket Head Cap Screw is integral to the secure assembly and operation of various engine components. It is employed in the coolant heater starting aid to ensure the reliable attachment of the preheater assembly, which is essential for efficient engine warm-up in cold conditions.

In the engine assembly, this screw plays a significant role in fastening the sensor components, ensuring accurate readings from the engine control system. It is also utilized in the full flow oil filter and lubricating oil filter assemblies to maintain the integrity of the filtration process, which is vital for engine longevity.

Furthermore, the screw is critical in the lubricating oil pressure assembly where it secures components that monitor and regulate oil pressure, directly influencing engine performance and protection. In the oil sensor assembly and pressure assembly for lubricating oil, it ensures that sensors are firmly in place, providing consistent and reliable data to the engine monitoring system.

Overall, the 3424432 Socket Head Cap Screw is a fundamental fastener across multiple engine systems, contributing to the secure and efficient operation of these components.

Conclusion

The 3424432 Socket Head Cap Screw by Cummins is a vital component in the assembly and maintenance of commercial trucks and various engine systems. Its design, material properties, and precise fastening capabilities ensure reliable performance in demanding applications. Proper installation, regular maintenance, and understanding its role in different engine components are essential for maximizing the efficiency and durability of these systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.