This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

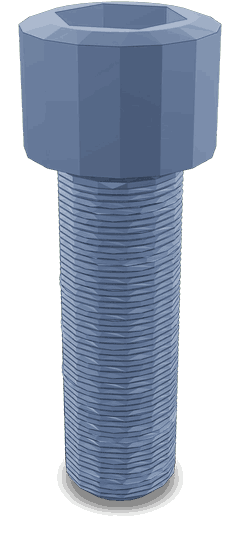

The Socket Head Cap Screw is a fundamental component in commercial truck maintenance, providing secure fastening solutions across various applications. Cummins, a renowned manufacturer in the industry, produces a range of high-quality fasteners, including the Socket Head Cap Screw Part #3428306. This screw is integral to the assembly and upkeep of commercial trucks, ensuring components remain securely fastened under demanding conditions.

Basic Concepts of Socket Head Cap Screws

A Socket Head Cap Screw is characterized by its cylindrical head with a hex socket, allowing for efficient tightening and loosening using a hex key. This design facilitates ease of use in confined spaces and reduces the risk of cam-out, a common issue with other drive types. Typically, these screws are made from materials such as alloy steel or stainless steel, chosen for their strength, durability, and resistance to corrosion. The material properties ensure that the screws can withstand significant stress and environmental exposure without degrading 1.

Purpose of the 3428306 Socket Head Cap Screw in Truck Operations

The 3428306 Socket Head Cap Screw by Cummins serves a pivotal role in the assembly and maintenance of commercial trucks. It is commonly used in applications where high strength and reliability are paramount, such as securing engine components, transmission parts, and chassis assemblies. Its design allows for precise torque application, ensuring that critical components remain securely fastened during operation 2.

Key Features of the 3428306 Socket Head Cap Screw

The 3428306 Socket Head Cap Screw features a hex socket drive and a fully threaded design, allowing for versatile application in various truck components. The screw’s thread specifications are tailored to provide optimal holding power, while the hex socket drive ensures easy installation and removal. These features contribute to the screw’s functionality and reliability, making it a preferred choice for demanding truck maintenance tasks 3.

Benefits of Using Socket Head Cap Screws

Socket Head Cap Screws offer several advantages over other types of fasteners. Their design allows for higher torque application without the risk of stripping, providing a secure fastening solution. Additionally, the materials used in their construction offer excellent corrosion resistance, ensuring longevity in harsh operating environments. The ease of use with hex keys further enhances their appeal for both installation and maintenance procedures.

Installation and Torque Specifications

Proper installation of the 3428306 Socket Head Cap Screw is crucial to ensure secure fastening. It is recommended to use a torque wrench to apply the specified torque settings, which vary depending on the application and material being fastened. Adhering to these guidelines helps prevent over-tightening, which can lead to damage, and under-tightening, which may result in loosening over time.

Troubleshooting Common Issues

Common issues with Socket Head Cap Screws include loosening due to vibration or thermal expansion and corrosion in exposed applications. To address loosening, ensure that the correct torque specifications are applied during installation. For corrosion, selecting screws made from corrosion-resistant materials or applying protective coatings can mitigate the issue. Regular inspection and maintenance can help identify and resolve these problems before they lead to component failure.

Maintenance Tips

Regular inspection and maintenance of Socket Head Cap Screws are vital to ensure their longevity and performance. Inspect screws for signs of wear, corrosion, or loosening during routine maintenance checks. Replace fasteners that show significant wear or damage to maintain the integrity of the assembly. Keeping screws clean and free from debris also contributes to their performance and lifespan.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, transmissions, and aftermarket parts, Cummins plays a significant role in enhancing the performance and reliability of commercial trucks. Their focus on quality ensures that components like the 3428306 Socket Head Cap Screw meet the high standards required for demanding truck applications.

Socket Head Cap Screw (Part 3428306) in Cummins Engines

The Socket Head Cap Screw (part 3428306) is a critical component in various Cummins engines, ensuring secure fastening and stability. This part is meticulously designed to fit seamlessly with the following engine models:

- QSV81G

- QSV91-G4 CM558/CM700 V102

- QSV91G

- QSW/QSV82

- QSW27

- QSW36

- QSW73

In the QSV81G and QSV91G engines, the Socket Head Cap Screw is used in several key areas, including the cylinder head and engine block, ensuring that these components remain tightly fastened under high operational stresses.

For the QSV91-G4 CM558/CM700 V102 engine, this screw is integral to maintaining the structural integrity of the engine’s critical components, such as the turbo housing and intake manifold.

In the QSW/QSV82 and QSW27 engines, the Socket Head Cap Screw is employed in various mounting points, ensuring that all parts are securely fastened and aligned correctly.

Similarly, in the QSW36 and QSW73 engines, this screw is used to secure the engine’s ancillary systems, such as the alternator and fuel injection system, ensuring optimal performance and reliability.

Each application of the Socket Head Cap Screw in these engines highlights its importance in maintaining the overall integrity and performance of the engine.

Role of Part 3428306 Socket Head Cap Screw in Engine Systems

In the intricate assembly of engine systems, the part 3428306 Socket Head Cap Screw serves as a fundamental fastening element. Its application is particularly significant in components such as dampers, vibration control systems, and vibration assembly dampers.

Damper Systems

Within damper systems, the Socket Head Cap Screw is employed to secure various components that mitigate mechanical vibrations. These screws ensure that the damper housings, which encase the damping fluid or mechanisms, remain firmly attached to the engine block or other structural elements. This secure attachment is essential for the damper to function effectively, absorbing and dissipating vibrations that could otherwise lead to component wear or failure.

Vibration Control Systems

In vibration control systems, the Socket Head Cap Screw plays a role in attaching vibration isolators to the engine framework. These isolators are designed to reduce the transmission of vibrations from the engine to the vehicle’s chassis, enhancing both comfort and durability. The screws must be torqued to precise specifications to maintain the integrity of the isolation system, ensuring that vibrations are adequately managed without compromising the structural stability of the engine mounting.

Vibration Assembly Dampers

For vibration assembly dampers, which are complex units often incorporating multiple damping technologies, the Socket Head Cap Screw is utilized to fasten critical components such as mounting brackets, sensor housings, and fluid reservoirs. The secure fastening provided by these screws is vital for the operational stability of the damper assembly, allowing it to perform its function of reducing engine vibrations across a range of operating conditions.

Throughout these applications, the consistent and reliable performance of the Socket Head Cap Screw is paramount. Its role in maintaining the structural and functional integrity of these components underscores the importance of proper installation and maintenance practices in engine system assemblies.

Conclusion

The 3428306 Socket Head Cap Screw by Cummins is a critical component in the maintenance and assembly of commercial trucks and engines. Its design, featuring a hex socket drive and fully threaded construction, ensures secure fastening and reliable performance under demanding conditions. Proper installation, regular maintenance, and adherence to torque specifications are essential to maximize the lifespan and effectiveness of this part. Cummins’ commitment to quality and innovation ensures that the 3428306 Socket Head Cap Screw meets the high standards required for commercial truck applications.

-

Barton, David C., and John D. Fieldhouse. Automotive Chassis Engineering Powertrain Chassis System and Vehicle Body. Elsevier, 2009.

↩ -

ElSayed, Mohamed. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.