This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Socket Head Cap Screw 3590770, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins is renowned for its high-quality components that enhance the performance and reliability of heavy-duty vehicles. This screw is integral to various truck assemblies, ensuring secure and durable connections that withstand the rigors of commercial operation.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. These screws are commonly used in mechanical assemblies where high strength and resistance to loosening are required. They provide a strong, threaded connection that can distribute load effectively across the joined components 1.

Purpose of Socket Head Cap Screw 3590770 in Truck Operations

This Cummins part plays a specific role in the operation and maintenance of commercial trucks. It is utilized in critical assemblies where secure fastening is paramount. This screw helps in maintaining the integrity of truck components under various operational stresses, ensuring that parts remain firmly attached and function as intended throughout the vehicle’s service life 2.

Key Features

The Socket Head Cap Screw 3590770 is distinguished by several key features that enhance its functionality. Its design includes a robust hexagonal socket that allows for precise and efficient tightening. The screw is made from high-quality materials, ensuring durability and resistance to corrosion. Additionally, its cap head design provides a low profile, reducing the risk of interference with other components 3.

Benefits of Using Socket Head Cap Screw 3590770

Employing this part in truck maintenance and assembly offers several advantages. Its high strength and durability ensure long-lasting connections, reducing the need for frequent replacements. The ease of use with a hex key allows for quick and secure tightening, enhancing efficiency during maintenance operations. Moreover, its reliable performance contributes to the overall safety and reliability of the truck 4.

Installation and Usage Guidelines

Proper installation of this part involves several steps to ensure a secure fit. Begin by selecting the appropriate hex key for the screw size. Insert the hex key into the socket and turn clockwise to tighten the screw. Ensure that the screw is fully seated and tightened to the manufacturer’s specified torque settings to achieve optimal performance. Using a torque wrench is recommended to maintain consistency and prevent over-tightening 5.

Troubleshooting and Maintenance

Common issues with Socket Head Cap Screws include loosening due to vibration and corrosion. To identify problems, regularly inspect screws for signs of wear or damage. Maintenance tips include applying a thread locker to prevent loosening and using corrosion-resistant coatings to extend the screw’s lifespan. Replacing screws that show significant wear or damage is also advisable to maintain the integrity of the assembly .

Safety Considerations

When handling and installing the Socket Head Cap Screw 3590770, it is important to observe several safety practices. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that the work area is clean and free from obstacles to prevent accidents. Follow all manufacturer guidelines and industry standards to ensure safe and effective installation .

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is committed to quality and innovation. The company’s extensive product range includes components for commercial trucks, buses, construction equipment, and more, all designed to meet the demanding requirements of heavy-duty applications.

Socket Head Cap Screw (Part 3590770) Compatibility with Cummins Engines

The Socket Head Cap Screw, identified by the part number 3590770, is a versatile component designed to fit a variety of Cummins engines. This part is integral in securing various engine components, ensuring structural integrity and operational efficiency. Below is a detailed breakdown of its compatibility across different Cummins engine models:

ISC Series

- ISC CM2150

- ISC8.3 CM2250

These engines, part of the ISC series, utilize the Socket Head Cap Screw in several critical applications. The screw’s design allows for secure fastening, which is essential for maintaining the alignment and stability of engine components.

ISL Series

- ISL CM2150

- ISL9 CM2150 SN

- ISL9 CM2250

The ISL series engines benefit from the Socket Head Cap Screw in various mounting and fastening tasks. Its robust construction ensures that the screw can withstand the operational stresses of these engines.

ISM Series

- ISM CM570/870

- ISM CM876

In the ISM series, the Socket Head Cap Screw is used to secure components that require precise alignment and fastening. Its design allows for easy installation and removal, facilitating maintenance and repair tasks.

ISX Series

- ISX CM870

- ISX CM871

- ISX12 CM2350 X102

- ISX12/ISX11.9 CM2250

- ISX15 CM2250

- ISX15 CM2350 X101

The ISX series engines, known for their high performance and reliability, incorporate the Socket Head Cap Screw in numerous applications. This screw is crucial for securing components that must endure high stress and vibration, ensuring the longevity and performance of the engine.

L GAS PLUS Series

- L GAS PLUS CM556

This model utilizes the Socket Head Cap Screw to maintain the integrity of its components, ensuring efficient and reliable operation.

QSB Series

- QSB4.5 CM2250 EC

- QSB4.5 CM850(CM2850)

The QSB series engines use the Socket Head Cap Screw in various fastening applications. Its design provides the necessary strength and durability to secure components under varying operational conditions.

QSC/QSL Series

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

These engines rely on the Socket Head Cap Screw for critical fastening tasks. The screw’s design ensures that components remain securely fastened, contributing to the overall reliability and performance of the engine.

QSX Series

- QSX11.9 CM2250 ECF

- QSX15 CM2250

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

The QSX series engines incorporate the Socket Head Cap Screw in various applications, ensuring that components are securely fastened and aligned. Its design is suited to the high-stress environments these engines operate in.

Role of Part 3590770 Socket Head Cap Screw in Various Engine Components

The part 3590770 Socket Head Cap Screw is a versatile fastener utilized across a range of engine components to ensure secure assembly and reliable performance. Its application spans several key areas within engine systems, contributing to the overall integrity and functionality of these components.

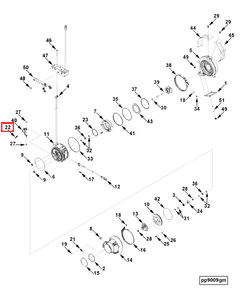

Turbocharger Systems

In turbocharger applications, the Socket Head Cap Screw is employed to fasten various parts together, ensuring a robust connection that can withstand the high-stress environments these systems operate in. Specifically, it is used in:

- Aftermarket Turbocharger: Secures components within the turbocharger, enhancing its durability and performance.

- Incomplete Turbocharger and Incomplete Turbocharger Kit: Plays a role in assembling the turbocharger, ensuring all parts are tightly held together.

- Turbocharger Bearing Housing: Fastens the bearing housing to the turbocharger, critical for maintaining the alignment and stability of the rotating assembly.

- Turbocharger Core and Turbocharger Kit: Used in the assembly of the core components, ensuring a secure fit that can handle the high rotational speeds and temperatures.

- Short Turbocharger Kit: Ensures the compact design of the kit is securely assembled, maintaining performance and reliability.

- Variable Geometry Repair Service Kit: Secures adjustable components, allowing for precise control over the turbocharger’s performance.

Engine Balancer

The Socket Head Cap Screw is also integral to the assembly of the engine balancer. It ensures that the balancer is securely attached to the engine, reducing vibrations and enhancing the engine’s overall smoothness and efficiency.

Repair and Service Kits

In repair and service kits, including the Repair Service Kit and Service Kit, the Socket Head Cap Screw is used to reassemble components after maintenance or repair work. This ensures that all parts are correctly and securely fastened, restoring the engine system to its optimal working condition.

Core Assembly

Within the core assembly of various engine components, the Socket Head Cap Screw provides the necessary tension and security to hold parts together. This is essential for the structural integrity of the assembly, ensuring it can withstand operational stresses.

Performance Parts

For performance parts, the Socket Head Cap Screw is often used to secure enhancements or modifications to the engine. This includes securing upgraded components that are designed to improve engine performance, ensuring they are firmly in place under high-stress conditions.

The Socket Head Cap Screw’s role in these components underscores its importance in maintaining the structural integrity, performance, and reliability of engine systems. Its application across a wide range of components highlights its versatility and essential nature in engine assembly and maintenance.

Conclusion

The Socket Head Cap Screw 3590770 is a critical component in the assembly and maintenance of Cummins engines and commercial trucks. Its robust design, ease of use, and compatibility with a wide range of engine models make it an indispensable part in ensuring the reliability and performance of heavy-duty vehicles. Proper installation, regular maintenance, and adherence to safety practices are essential to maximize the benefits of this part.

-

Aird, Forbes. Bosch Fuel Injection Systems. HP Books, 2001.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ -

Bonneau, Dominique, Aurelian Fatu, and Dominique Souchet. Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE, 2014.

↩ -

Cummins Inc. Owners Manual. Bulletin Number 5467254, QSG12 CM2350 G113.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.