3681898

Socket Head Cap Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Socket Head Cap Screw 3681898, produced by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a leading manufacturer in the automotive and heavy-duty truck industries, ensures that this part meets the rigorous demands of commercial vehicle operations 1.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. These screws are commonly used in mechanical assemblies requiring high strength and resistance to loosening. They provide a secure connection between components, distributing load evenly and resisting rotational forces 2.

Purpose of Socket Head Cap Screw 3681898 in Truck Operations

This Cummins part is integral to the operation and maintenance of commercial trucks. It is used in applications where secure fastening is crucial, such as in engine components and chassis assemblies. The screw helps maintain the integrity of mechanical connections, ensuring that components remain securely fastened under various operating conditions 3.

Key Features of Socket Head Cap Screw 3681898

The Socket Head Cap Screw 3681898 is crafted from high-quality materials, ensuring durability and resistance to corrosion. It features a precise hexagonal socket for easy installation and removal using a hex key. Additionally, its design includes a countersunk head, which allows it to sit flush with or below the surface of the material being fastened, reducing the risk of snagging or interference.

Benefits of Using Socket Head Cap Screw 3681898

Incorporating this part in truck assemblies offers several advantages. Its high-strength material ensures durability under heavy loads and harsh conditions. The hexagonal socket design allows for easy and precise tightening, reducing the risk of over-tightening or stripping. Additionally, the screw’s resistance to loosening helps maintain secure connections over time, enhancing the reliability of mechanical assemblies.

Installation and Usage Guidelines

Proper installation of the Socket Head Cap Screw 3681898 is crucial for ensuring its effectiveness. Use a hex key that matches the size of the screw’s socket. Ensure the mating surfaces are clean and free of debris to promote a secure connection. Tighten the screw to the manufacturer’s specified torque settings to avoid over-tightening, which can damage the screw or the material being fastened. Regularly inspect the screw for signs of wear or loosening and retighten as necessary.

Troubleshooting Common Issues

Frequent problems associated with Socket Head Cap Screws include loosening over time, corrosion, and damage to the socket. To address loosening, ensure the screw is tightened to the correct torque and inspect the mating surfaces for proper alignment. Corrosion can be mitigated by using screws made from corrosion-resistant materials and applying a protective coating if necessary. If the socket is damaged, replace the screw to ensure secure fastening.

Maintenance Tips

Regular maintenance practices are essential for ensuring the longevity and reliability of the Socket Head Cap Screw 3681898. Inspect the screw periodically for signs of wear, corrosion, or loosening. Clean the mating surfaces and retighten the screw as needed. Replace the screw if it shows significant wear or damage. Following these maintenance routines will help maintain the integrity of mechanical connections in commercial trucks.

Cummins: A Brief Overview

Cummins is a leading manufacturer in the automotive and heavy-duty truck industries, with a rich history of innovation and quality. The company specializes in diesel engines and components, providing reliable and high-performance solutions for commercial vehicles. Cummins is committed to advancing technology and improving the efficiency and durability of their products, making them a trusted name in the industry.

Socket Head Cap Screw 3681898 in Cummins Engines

This part is a critical component in several Cummins engine models, ensuring structural integrity and operational efficiency. Below is a detailed description of how this part fits within the specified engines:

ISX Series Engines

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

This part is utilized in the ISX series engines for securing various components, including engine blocks, cylinder heads, and other critical assemblies. Its design ensures that these parts remain tightly fastened, reducing the risk of mechanical failure and enhancing engine performance.

QSX Series Engines

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

In the QSX series engines, this part plays a similar role. It is used to secure components that require precise fastening to maintain the structural and operational integrity of the engine. This includes securing the engine block and other vital parts that are subject to high stress and vibration.

X15 Series Engines

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

For the X15 series engines, this part is employed in securing various engine components. This includes fastening parts that are integral to the engine’s operation, ensuring that all parts remain securely in place under the demanding conditions of engine operation.

N14 Series Engine

- N14 CELECT PLUS

In the N14 CELECT PLUS engine, this part is used to secure critical components, ensuring that the engine maintains its structural integrity and operational efficiency. This part is essential in maintaining the alignment and fastening of various engine parts, contributing to the overall reliability of the engine.

Role of Part 3681898 Socket Head Cap Screw in Various Engine Components

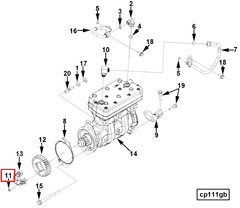

Air Compressor and Compressor Systems

In air compressor and compressor systems, 3681898 is utilized to secure various components that contribute to the efficient compression of air. These screws are often found fastening the compressor housing to the engine block, ensuring a stable and leak-free connection. Additionally, they may be used to attach the compressor pulley to the front gear train accessory, maintaining alignment and reducing the risk of mechanical failure.

Drive Systems

Within drive systems, the Socket Head Cap Screw plays a significant role in securing components that transfer power from the engine to other parts of the machinery. For instance, it is commonly used to fasten the drive belt tensioner, which is essential for maintaining the correct tension on the drive belts. This ensures optimal performance and longevity of the belts, as well as the smooth operation of connected accessories.

Front Gear Train Accessory

The front gear train accessory is a complex assembly that often requires precise fastening to ensure proper function. This part is employed to secure various gears and components within this accessory. Its design allows for a strong and durable connection, which is vital for the reliable operation of the gear train. This, in turn, contributes to the overall efficiency and performance of the engine.

Hydraulic Pump Adapter

In hydraulic systems, the hydraulic pump adapter is a critical component that connects the hydraulic pump to the engine. The Socket Head Cap Screw is used to secure this adapter, ensuring a robust and leak-free connection. This is particularly important in high-pressure hydraulic systems, where any failure in the connection could lead to significant issues. The screw’s design provides the necessary strength and stability to withstand the pressures and forces involved in hydraulic operations.

Conclusion

The Socket Head Cap Screw 3681898 by Cummins is a versatile and essential component in various engine models and systems. Its high-quality design and materials ensure durability, resistance to corrosion, and secure fastening, contributing to the overall reliability and performance of commercial trucks. Proper installation, regular maintenance, and timely replacement are crucial for maintaining the integrity of mechanical connections and ensuring the longevity of this part.

-

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Zhan, Q., Eben, S., & Deng, L. K. (2018). Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning.

↩ -

ElSayed, M. (2017). Fundamentals of Integrated Vehicle Realization. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.