Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Fracture Resistant Screw 3692564, manufactured by Cummins, is a specialized component designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is renowned for its high-quality parts and engines. The 3692564 screw is significant in the realm of truck maintenance and operation due to its enhanced durability and resistance to fracture under stress 1.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are engineered to withstand significant stress without breaking. In the automotive industry, these screws are utilized in various applications where components are subject to high levels of stress and vibration. They function by distributing stress more evenly across their structure, which helps prevent failure under load. This is particularly important in commercial trucks, where components are often exposed to harsh operating conditions 2.

Purpose of Fracture Resistant Screw 3692564 in Truck Operations

The 3692564 screw plays a specific role in the operation and maintenance of commercial trucks. It is used in various truck components where durability and reliability are paramount. This includes applications in the engine assembly, transmission systems, and other critical areas where the screw’s fracture resistance can contribute to the overall stability and longevity of the truck 3.

Key Features

The 3692564 screw boasts several key features that enhance its performance. It is composed of high-strength materials, which contribute to its durability. The design incorporates elements that improve fracture resistance, such as a specialized thread pattern and a robust core. Additionally, unique manufacturing processes are employed to ensure the screw meets the stringent requirements of commercial truck applications 4.

Benefits of Using Fracture Resistant Screws

Incorporating fracture resistant screws like the 3692564 in truck assemblies offers several advantages. These screws contribute to increased durability of the components they secure, which can lead to reduced maintenance needs. Furthermore, their enhanced resistance to fracture under stress can improve the safety and reliability of the truck, making them a valuable component in commercial fleet management 5.

Installation Considerations

Proper installation of the 3692564 screw is vital to ensure optimal performance and longevity. Guidelines for installation include using the correct torque specifications to avoid over-tightening, which can lead to screw failure, or under-tightening, which can result in loose connections. It is also important to ensure that the screw is compatible with the specific application and that all mating surfaces are clean and free of debris 6.

Troubleshooting Common Issues

Common problems associated with fracture resistant screws may include loosening over time due to vibration or corrosion. Potential causes can range from improper installation to environmental factors. Recommended troubleshooting steps involve inspecting the screw and its surroundings for signs of wear or damage, ensuring proper torque is applied during reinstallation, and addressing any environmental factors that may contribute to corrosion 7.

Maintenance Tips

Regular maintenance practices can help prolong the life of the 3692564 screw and ensure continued reliable performance. This includes periodic inspections for signs of wear or damage, ensuring that all connections remain tight, and addressing any corrosion promptly. Additionally, maintaining a clean operating environment can help prevent contaminants from affecting the screw’s performance 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle applications 9.

Fracture Resistant Screw Part 3692564 Compatibility with Cummins Engines

The Fracture Resistant Screw part number 3692564, manufactured by Cummins, is designed to fit seamlessly into a variety of Cummins engine models. This part is crucial for maintaining the structural integrity of the engine by preventing fractures that could lead to catastrophic failures 10.

ISG11 CM2880 G108 and ISG12 CM2880 G107

These engines, both part of the ISG series, utilize the Fracture Resistant Screw in their assembly. The screw is integral to the engine’s design, ensuring that the components remain securely fastened under high stress conditions. This is particularly important in the CM2880 models, where durability and reliability are paramount 11.

ISG12 G CMOH6.0 G111 and QSG12 CM2880 G112

The ISG12 G CMOH6.0 G111 and QSG12 CM2880 G112 engines also benefit from the use of the Fracture Resistant Screw. These engines are known for their robust performance, and the screw plays a key role in maintaining the integrity of the engine’s components. Its design ensures that it can withstand the rigors of continuous operation without succumbing to fatigue or fracture 12.

QSG12/X12 CM2350 G110 and X12 CM2670 X121B

For the QSG12/X12 CM2350 G110 and X12 CM2670 X121B engines, the Fracture Resistant Screw is equally essential. These engines are designed for high-performance applications, and the screw’s ability to resist fractures under extreme conditions is critical. Its use in these models ensures that the engine can operate at peak efficiency without the risk of mechanical failure due to screw degradation 13.

Role of Part 3692564 Fracture Resistant Screw in Engine Systems

Part 3692564, a fracture-resistant screw, is integral to the assembly and maintenance of various engine components. Its application ensures the secure fastening of parts, contributing to the overall stability and performance of the engine 14.

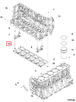

Cylinder Block

In the cylinder block, part 3692564 is utilized to fasten critical components such as the cylinder head, main bearing caps, and various brackets. The screw’s fracture-resistant properties are particularly beneficial in this high-stress environment, where vibrations and thermal expansions are common. By providing a reliable fastening solution, it helps maintain the precise alignment of the cylinder bores, which is essential for efficient combustion and engine longevity 15.

Cylinder Block Kit

When assembling a cylinder block kit, part 3692564 plays a significant role in securing the new or refurbished components. This includes fastening the cylinder sleeves, gaskets, and other ancillary parts that are part of the kit. The fracture-resistant nature of the screw ensures that these components remain firmly in place throughout the engine’s operational life, reducing the risk of misalignment or component failure 16.

Conclusion

In summary, the Fracture Resistant Screw part number 3692564 is a vital component for a range of Cummins engines, providing the necessary strength and durability to maintain engine integrity across various models and applications. Its use in critical engine components ensures secure fastening, contributing to the overall stability and performance of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

-

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩ -

Duffy, Owen C and Wright, Gus. Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning, 2016.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Mananathan, R. Automobile Wheel Alignment and Wheel Balancing. SAE International, 2022.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.