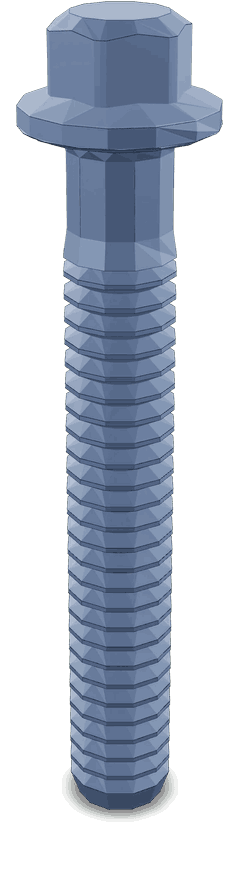

3695503

Connecting Rod Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3695503 Connecting Rod Cap Screw is a critical component in heavy-duty truck engines. This part secures the connecting rod to the crankshaft, playing a vital role in the engine’s operation by ensuring efficient transfer of power from the piston to the crankshaft. Understanding its function and importance is essential for maintaining engine performance and reliability.

Basic Concepts of Connecting Rod Cap Screws

Connecting rod cap screws are fundamental to engine operation. They secure the connecting rod to the crankshaft, ensuring that the force generated by the piston’s movement is efficiently transferred to the crankshaft. This transfer is essential for the engine’s overall performance and reliability. The screws must withstand high stress and maintain a secure connection under varying engine conditions 1.

Purpose of the 3695503 Connecting Rod Cap Screw

The 3695503 Connecting Rod Cap Screw is designed to secure the connecting rod to the crankshaft in truck engines. This connection is vital for maintaining the integrity of the engine’s moving parts. By ensuring a tight and secure fit, the screw helps in the efficient transfer of power from the piston to the crankshaft, contributing to the engine’s smooth operation and durability 2.

Key Features

The 3695503 Connecting Rod Cap Screw features several key attributes that enhance its performance and durability. It is made from high-quality materials, ensuring it can withstand the high stress and temperatures within the engine. The screw’s threading specifications are precisely engineered to provide a secure fit, while its design characteristics are optimized for durability and efficiency 3.

Benefits

Using the 3695503 Connecting Rod Cap Screw offers several benefits. It contributes to improved engine reliability by ensuring a secure connection between the connecting rod and the crankshaft. This security enhances the engine’s performance and longevity, leading to more efficient and safer operation of heavy-duty trucks. The screw’s design and material composition also contribute to its durability, reducing the need for frequent replacements 4.

Installation and Maintenance

Proper installation of the 3695503 Connecting Rod Cap Screw is crucial for its performance and the engine’s reliability. It should be installed according to the manufacturer’s torque specifications to ensure a secure fit. Routine maintenance and inspection are recommended to ensure the screw remains in optimal condition. This includes checking for signs of wear or loosening and addressing any issues promptly to prevent engine damage 5.

Troubleshooting Common Issues

Common problems associated with connecting rod cap screws include loosening, wear, or failure. These issues can lead to engine performance problems if not addressed. Troubleshooting methods involve inspecting the screw for signs of damage or wear, ensuring it is properly torqued, and replacing it if necessary. Addressing these issues effectively helps maintain the engine’s performance and reliability 6.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the engine industry, known for its commitment to quality and innovation. With a rich history of engine manufacturing, Cummins has established itself as a trusted provider of reliable and efficient engine components. Its expertise and dedication to excellence have made it a key player in the automotive industry, contributing to the development of advanced engine technologies 7.

Compatibility of 3695503 Connecting Rod Cap Screw with Cummins Engines

The 3695503 Connecting Rod Cap Screw is compatible with various Cummins engine models, including:

- ISG11 CM2880 G108 and ISG12 CM2880 G107: These engines utilize the screw to maintain the alignment and stability of the connecting rod, crucial for the smooth operation of the crankshaft.

- ISG12 G CMOH6.0 G111: This engine variant incorporates the screw to ensure the connecting rod cap remains securely fastened, preventing misalignment and mechanical failure.

- QSG12 CM2880 G112 and QSG12/X12 CM2350 G110: These engines use the screw to provide the necessary clamping force to keep the connecting rod cap in place, ensuring the crankshaft’s smooth rotation.

- X11 CM2670 X126B and X12 CM2350 X119B: These engines use the screw to secure the connecting rod cap, maintaining the structural integrity of the engine and preventing potential movement that could compromise performance.

- X12 CM2670 X121B and X12N CMMDG1 X143B: These engines are compatible with the screw to ensure the connecting rod cap is tightly secured, essential for the engine’s overall stability and efficiency.

- X13 CM2670 X122B: This engine uses the screw to maintain the alignment of the connecting rod cap, critical for the smooth operation of the crankshaft and the engine’s overall performance.

Role of 3695503 Connecting Rod Cap Screw in Engine Systems

The 3695503 Connecting Rod Cap Screw plays a significant role in ensuring the structural integrity and precise functioning of several key components within the engine system.

Interaction with Connecting Rod and Piston

The screw is essential in securing the connecting rod to the crankshaft. This connection is vital as it transfers the linear motion of the piston into rotational motion of the crankshaft. The screw ensures that the connecting rod remains firmly attached to the crankshaft, allowing for efficient power transmission from the piston’s movement 8.

Integration with Engine Connecting Rod

Within the engine, the connecting rod is a pivotal component that links the piston to the crankshaft. The connecting rod cap screw fastens the rod cap to the rod body, maintaining the alignment and balance necessary for smooth engine operation. This secure attachment minimizes wear and reduces the risk of mechanical failure under high stress and RPMs 9.

Relationship with Engine Piston

The engine piston moves up and down within the cylinder, driven by the combustion process. The connecting rod cap screw indirectly affects the piston’s performance by ensuring that the connecting rod is securely fastened. This security allows the piston to operate within its designed parameters, contributing to consistent engine performance and reliability 10.

Contribution to Engine Piston Kit

An engine piston kit typically includes pistons, connecting rods, and associated hardware. The connecting rod cap screw is a fundamental part of this kit, providing the necessary tension and stability to the connecting rod assembly. Its proper installation is key to the overall functionality and durability of the piston kit 11.

Importance in Performance Parts

For those seeking to enhance engine performance, the connecting rod cap screw is often overlooked but is equally important. High-performance engines demand components that can withstand greater stress and higher RPMs. The connecting rod cap screw must be of superior quality to handle these increased demands, ensuring that the connecting rod remains intact and functions optimally under extreme conditions 12.

Conclusion

The 3695503 Connecting Rod Cap Screw is a vital component in heavy-duty truck engines, ensuring the secure connection between the connecting rod and the crankshaft. Its proper installation and maintenance are crucial for maintaining engine performance and reliability. Understanding its role and importance can help in the efficient operation and longevity of heavy-duty engines.

-

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358361.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358361.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Zhao, H. (2010). Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines. CRC Press.

↩ -

Kluczyk, B. (2008). How to Rebuild Any Automotive Engine. CarTech.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4358361.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.