4006200

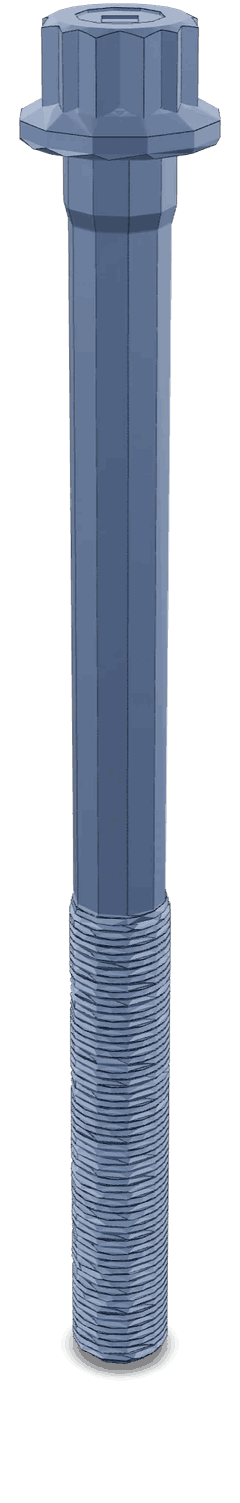

Twelve Point Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Twelve Point Cap Screw, identified by part number 4006200, is a specialized fastener produced by Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry. This screw is integral to the assembly and maintenance of commercial trucks, ensuring secure fastening in various applications. Cummins’ reputation for quality and reliability underscores the significance of this component in the industry.

Basic Concepts and Functionality

A Twelve Point Cap Screw is a type of bolt characterized by its twelve-sided head, which provides a larger contact area compared to traditional hex-head screws. This design allows for more torque to be applied without the risk of rounding off the head, which is particularly beneficial in high-stress applications. In commercial trucks, these screws play a role in fastening applications by securely joining components together, ensuring structural integrity and operational reliability 1.

Purpose and Role in Truck Operation

The 4006200 Twelve Point Cap Screw serves a specific purpose in truck operations by providing robust fastening solutions in various components. It is commonly used in engine assemblies, chassis construction, and other critical areas where high torque and resistance to loosening are required. Its role is to maintain the integrity of these assemblies under the demanding conditions encountered in commercial trucking.

Key Features

The 4006200 Twelve Point Cap Screw features a unique twelve-sided head design that enhances its performance. It is typically made from high-strength materials, such as alloy steel, to ensure durability and resistance to wear. The screw’s design allows for greater torque application without stripping, and its material composition contributes to its longevity in heavy-duty applications.

Benefits

The advantages of the 4006200 Twelve Point Cap Screw include improved torque application due to its twelve-sided head, which reduces the likelihood of rounding. Its resistance to stripping ensures that it can withstand high torque without failure. Additionally, the screw’s durable material composition enhances its reliability in demanding environments, making it suitable for heavy-duty applications.

Installation and Usage Guidelines

Proper installation of the 4006200 Twelve Point Cap Screw involves using the correct torque specifications to ensure optimal performance and longevity. It is important to follow best practices, such as using a torque wrench to apply the recommended torque and ensuring that the screw is properly seated in the application. These guidelines help to maintain the integrity of the fastening and prevent issues such as loosening or failure 2.

Troubleshooting and Maintenance

Common issues with the 4006200 Twelve Point Cap Screw may include loosening due to vibration or corrosion in exposed applications. Regular inspection and maintenance, such as tightening screws to the specified torque and applying corrosion-resistant coatings, can help prevent these issues. Addressing problems promptly ensures continued reliability and performance of the fastening.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to producing high-quality components. The company’s expertise and dedication to excellence are reflected in its products, including the 4006200 Twelve Point Cap Screw.

Role of Part 4006200 Twelve Point Cap Screw in Engine Systems

The 4006200 Twelve Point Cap Screw is integral in securing and maintaining the integrity of various engine components. It is commonly used in the assembly and maintenance of the camshaft, where it ensures the camshaft is properly aligned and secured within the cylinder head. This alignment is essential for the camshaft to operate the valve train accurately, which in turn affects the engine’s performance and efficiency.

In the connecting rod and piston assembly, the Twelve Point Cap Screw plays a role in securing the connecting rod to the crankshaft. This connection is vital for transferring the piston’s linear motion to the crankshaft’s rotational motion, directly influencing the engine’s power output and smoothness of operation.

Within the cylinder head, the Twelve Point Cap Screw is often used to secure various components such as the injector and rocker arms. Proper securing of these components ensures that the fuel injection is precise and that the valve operation is consistent, both of which are fundamental to engine performance.

The screw is also utilized in the assembly of the head and cylinder, where it helps in maintaining the seal and structural integrity between these components. This is important for preventing leaks and ensuring that the combustion process is efficient.

Additionally, the Twelve Point Cap Screw is employed in the attachment of levers and other parts that contribute to the overall performance of the engine. Its use in these applications underscores the importance of secure fastening in achieving optimal engine operation and longevity.

Conclusion

The Twelve Point Cap Screw 4006200 is a vital component in the assembly of Cummins engines, including the QSK78 CM500, ensuring the secure and stable operation of the engine’s critical parts. Its unique design and high-strength material composition make it suitable for heavy-duty applications, contributing to the overall reliability and performance of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.