4006384

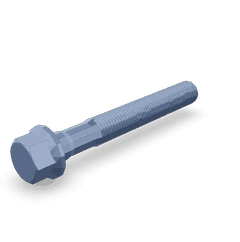

Hexagon Flange Head Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4006384 Hexagon Flange Head Cap Screw is a specialized fastener designed for use in commercial truck applications. Its purpose is to provide secure and reliable fastening in various truck components and systems. This screw is significant in ensuring the integrity and performance of truck assemblies, contributing to the overall efficiency and safety of commercial vehicles 1.

Basic Concepts

Hexagon Flange Head Cap Screws are characterized by their hexagonal head and flanged design. The hexagonal head allows for easy tightening and loosening using a wrench or socket, while the flange provides additional surface area for distribution of clamping force. These screws are commonly used in mechanical assemblies where high strength and resistance to loosening are required 2. They play a role in securing components together, ensuring structural integrity and proper function of the assembly.

Purpose and Role in Truck Operation

The Cummins 4006384 Hexagon Flange Head Cap Screw plays a specific role in the operation of commercial trucks by securing various components and systems. It is used in applications such as engine mounts, transmission housings, and chassis assemblies. By providing a strong and reliable fastening solution, this screw helps maintain the structural integrity and performance of critical truck components, contributing to the overall reliability and safety of the vehicle 3.

Key Features

The Cummins 4006384 Hexagon Flange Head Cap Screw features a hexagonal flange head design, which allows for easy installation and removal using standard tools. It is typically made from high-strength materials such as alloy steel, providing excellent durability and resistance to corrosion. The screw has precise thread specifications to ensure proper engagement and clamping force. Additionally, it may have unique characteristics such as a black oxide coating for enhanced corrosion resistance or a locking mechanism to prevent loosening under vibration 4.

Benefits

Using the Cummins 4006384 Hexagon Flange Head Cap Screw in commercial truck applications offers several benefits. Its design and material composition provide improved fastening performance, ensuring secure and reliable connections in demanding environments. The screw’s resistance to loosening under vibration helps maintain proper clamping force over time, reducing the risk of component failure or detachment. Additionally, its durability and corrosion resistance contribute to the longevity and reliability of truck assemblies 5.

Installation Guidelines

Proper installation of the Cummins 4006384 Hexagon Flange Head Cap Screw is crucial for ensuring secure and reliable fastening. Follow these guidelines for installation:

- Use the appropriate wrench or socket to tighten the screw to the specified torque value. Refer to the manufacturer’s recommendations for torque specifications.

- Ensure that the mating surfaces are clean and free from debris to promote proper engagement and clamping force.

- Avoid over-tightening, as this can lead to damage to the screw or surrounding components.

- Use thread locker or locking mechanism, if applicable, to prevent loosening under vibration 6.

Maintenance and Troubleshooting

Regular maintenance and inspection of the Cummins 4006384 Hexagon Flange Head Cap Screw are important for ensuring continued performance and reliability. Inspect the screw periodically for signs of corrosion, loosening, or damage. If corrosion is detected, clean the affected area and apply a corrosion-resistant coating if necessary. If loosening is observed, re-tighten the screw to the specified torque value and consider using a thread locker or locking mechanism to prevent future loosening. Replace the screw if significant damage or wear is detected 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services to meet the diverse needs of its customers, including engines, powertrain components, and aftermarket parts. Cummins’ commitment to excellence and customer satisfaction has made it a trusted partner in the commercial truck industry 8.

Hexagon Flange Head Cap Screw in Engine Systems

The Hexagon Flange Head Cap Screw, part number 4006384, is integral to the assembly and maintenance of various engine components. Its design allows for secure fastening, which is essential for the reliable operation of engine systems.

Camshaft and Camshaft Replacer

In the camshaft assembly, the Hexagon Flange Head Cap Screw is used to fasten the camshaft to the cylinder head. This ensures precise alignment and reduces the risk of misalignment during operation. When replacing a camshaft, these screws provide the necessary torque to secure the new component in place, ensuring smooth valve operation 9.

Connecting Rod and Piston

For the connecting rod and piston assembly, these screws are employed to secure the connecting rod cap to the rod body. This connection is vital for maintaining the integrity of the piston’s movement within the cylinder, directly influencing engine performance and durability 10.

Cylinder Head and Cylinder Liner Replacer

When installing or replacing the cylinder head, Hexagon Flange Head Cap Screws are used to fasten the head to the engine block. This secure attachment is necessary for maintaining compression and preventing leaks. Similarly, in cylinder liner replacement, these screws help in securing the liner to the engine block, ensuring a tight seal and proper engine function 11.

Engine Repair Stand Kit and Housing

In an engine repair stand kit, these screws are utilized to assemble the stand, providing a stable and secure platform for engine work. Within the engine housing, they are crucial for fastening various components, ensuring that the housing remains intact during engine operation 12.

Thermostat and Injector Kit

The thermostat housing often requires secure fastening to prevent coolant leaks, and the Hexagon Flange Head Cap Screws are ideal for this application. In injector kits, these screws are used to mount injectors to the cylinder head, ensuring they are held firmly in place for consistent fuel delivery 13.

Lever, Rocker, and Rocker Lever

For lever and rocker assemblies, these screws are used to fasten the rockers to the cylinder head. This secure attachment is essential for transmitting motion from the camshaft to the valves, ensuring timely and efficient valve operation 14.

Seal Kit and Service Kit

In seal kits, these screws may be used to secure components within the seal assembly, ensuring a tight fit and preventing leaks. Within service kits, they are often included for various fastening applications, providing reliability and ease of use during maintenance procedures 15.

Single Cylinder Gasket Kit

When assembling a single cylinder gasket kit, these screws are used to secure gaskets and other components, ensuring a proper seal and preventing any form of leakage that could compromise engine performance 16.

Front and Rear Engine Support

For front and rear engine support systems, Hexagon Flange Head Cap Screws are used to secure mounting brackets and other support components. This ensures the engine is firmly attached to the vehicle’s frame, providing stability and reducing vibrations during operation 17.

Ignition System

In ignition systems, these screws are used to secure ignition components to the engine, ensuring reliable spark delivery for combustion. This is essential for consistent engine start-up and operation 18.

Conclusion

The Cummins 4006384 Hexagon Flange Head Cap Screw is a critical component in the assembly and maintenance of various engine components. Its design allows for secure fastening, which is essential for the reliable operation of engine systems. Proper installation, maintenance, and understanding of its role in engine systems are crucial for ensuring the longevity and performance of commercial trucks.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5579475.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.