This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

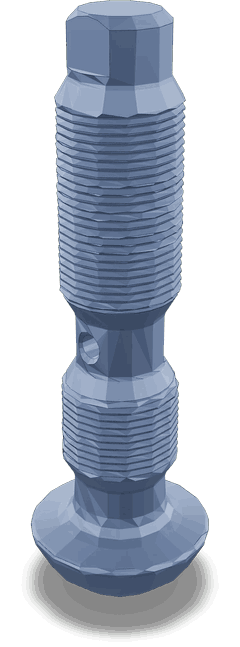

The Crosshead Adjustment Screw 4015023 is a specialized component designed by Cummins for use in heavy-duty truck engines. This screw plays a role in fine-tuning the alignment and operation of the crosshead within the engine, contributing to the overall efficiency and performance of the vehicle. Its proper function is integral to maintaining the precision and reliability of the engine’s moving parts 1.

Purpose and Function

The Crosshead Adjustment Screw is instrumental in the operation of the engine by allowing for precise adjustments to the crosshead’s position. This adjustment facilitates optimal alignment between the piston, connecting rod, and crankshaft, ensuring smooth and efficient power transmission. By maintaining proper alignment, the screw contributes to minimizing friction and wear on these critical components, thereby enhancing engine performance and longevity 2.

Key Features

The Crosshead Adjustment Screw 4015023 is crafted from high-quality materials, ensuring durability and resistance to the harsh conditions within an engine environment. Its design incorporates a threaded mechanism that allows for fine adjustments, providing technicians with the precision needed for optimal engine performance. The screw’s construction is robust, capable of withstanding significant stress and vibration without compromising its integrity 3.

Benefits

Incorporating the Crosshead Adjustment Screw into an engine’s design offers several advantages. It contributes to improved engine efficiency by ensuring that all moving parts operate in harmony. This alignment reduces unnecessary wear on connecting components, leading to a longer engine lifespan. Additionally, the precise adjustments afforded by the screw enhance overall engine performance, allowing for more consistent power delivery and reduced maintenance requirements 4.

Installation and Maintenance

Proper installation of the Crosshead Adjustment Screw is crucial for its effective function. It is recommended that installation be performed by a qualified technician using the appropriate tools to ensure accuracy and safety. Regular maintenance checks are advised to verify the screw’s alignment and condition, allowing for timely adjustments or replacements as needed. This proactive approach helps maintain engine efficiency and prevents potential issues arising from misalignment 1.

Troubleshooting Common Issues

Common issues associated with the Crosshead Adjustment Screw may include misalignment or wear over time. Symptoms of these problems can manifest as increased engine noise, reduced performance, or abnormal wear patterns on connected components. Troubleshooting these issues involves carefully inspecting the screw and its surrounding components for signs of damage or misalignment. Adjustments or replacements may be necessary to restore optimal engine function 2.

Safety Considerations

When working with the Crosshead Adjustment Screw, it is important to observe safety protocols to prevent accidents. This includes ensuring the engine is properly shut down and cooled before beginning any work. Additionally, using the correct tools and following recommended procedures can help avoid injuries and ensure the safe operation of the engine. Always refer to the manufacturer’s guidelines for specific safety instructions and precautions 3.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive industry. The company’s product range includes engines and components for heavy-duty trucks, among other applications, demonstrating its commitment to powering a more prosperous world 4.

Compatibility with Cummins Engines

The Crosshead Adjustment Screw, identified by part number 4015023, is compatible with several Cummins engines, including the QSV81G, QSV91G, and QSV91-G4 CM558/CM700 V102. These engines are known for their robust design and reliability, often used in heavy-duty applications. The screw plays a pivotal role in maintaining the alignment of the crosshead, ensuring smooth operation and reducing wear on critical components.

Role in Engine Systems

This Cummins part is integral to the precise operation of various engine components. It ensures the optimal alignment and performance of the cylinder head conversion kit, which is essential for efficient combustion and power output.

In the valve train mechanism, the Crosshead Adjustment Screw works in conjunction with the lever and rocker to maintain the correct valve clearance. This is vital for the timely opening and closing of the valves, which directly affects engine performance and longevity.

Additionally, the screw interacts with the rocker lever support to ensure that the rocker arm operates within its designed parameters. This interaction is key to preventing undue stress on the valve train components, thereby enhancing the reliability and durability of the engine system.

Through its role in these components, the Crosshead Adjustment Screw contributes to the overall efficiency and reliability of the engine, ensuring that each part operates in harmony with the others.

Conclusion

The Crosshead Adjustment Screw 4015023 by Cummins is a critical component in the maintenance and operation of heavy-duty truck engines. Its role in ensuring precise alignment and adjustment of the crosshead contributes significantly to engine efficiency, performance, and longevity. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the benefits of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the Crosshead Adjustment Screw, making it a valuable component in the automotive industry.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books, 2023.

↩ ↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩ ↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ ↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.