This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Socket Head Cap Screw 4079166, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-established name in the automotive industry, is known for its robust and reliable components. This particular screw is integral to the maintenance and operation of commercial trucks, ensuring secure fastening in various mechanical assemblies.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for efficient and secure tightening using a hex key. These screws are widely used in mechanical applications due to their ability to provide strong, durable connections. They function by converting torque applied by a tool into clamping force, which holds components together securely 1.

Purpose of Socket Head Cap Screw 4079166 in Truck Operations

The Socket Head Cap Screw 4079166 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in applications where high strength and resistance to loosening are required. This screw helps in securing critical components, ensuring that they remain firmly in place under various operational conditions, thereby contributing to the overall reliability and safety of the truck 2.

Key Features

The Socket Head Cap Screw 4079166 is distinguished by several key features. Its design includes a hexagonal socket head, which allows for precise and efficient tightening. The screw is made from high-quality materials, ensuring durability and resistance to wear. Additionally, it may feature a corrosion-resistant coating, enhancing its performance in harsh environments commonly encountered in commercial truck operations.

Benefits of Using Socket Head Cap Screw 4079166

Utilizing the Socket Head Cap Screw 4079166 offers several advantages. Its robust construction ensures long-lasting performance, reducing the need for frequent replacements. The design of the screw facilitates easy installation, saving time during maintenance procedures. Furthermore, its resistance to loosening helps maintain secure fastenings, which is crucial for the safe operation of commercial trucks.

Installation and Usage Guidelines

Proper installation of the Socket Head Cap Screw 4079166 involves several steps. First, ensure the mating surfaces are clean and free of debris. Use the appropriate hex key to drive the screw into the pre-drilled hole. Apply steady torque to achieve the recommended tightening specification, which can typically be found in the vehicle’s maintenance manual. It is important to avoid over-tightening, which can damage the screw or the surrounding components.

Maintenance Tips

To ensure the longevity and optimal performance of the Socket Head Cap Screw 4079166, regular maintenance is recommended. Periodically check the screw for signs of wear or loosening. If corrosion is present, clean the screw and surrounding area, and consider applying a protective coating. Regular inspections help identify potential issues before they lead to more significant problems.

Troubleshooting Common Issues

Common issues with Socket Head Cap Screws include loosening, corrosion, and wear. If a screw appears loose, re-tighten it to the specified torque. Corrosion can often be addressed by cleaning the screw and applying a corrosion-resistant treatment. Worn screws should be replaced to maintain the integrity of the fastening.

Safety Considerations

When working with Socket Head Cap Screws, it is important to follow safety guidelines. Wear appropriate personal protective equipment, such as gloves and safety glasses, to protect against injury. Ensure that tools are in good condition and used correctly to avoid accidents. Always refer to the manufacturer’s guidelines for safe handling and installation practices.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins is renowned for its innovation, quality, and commitment to customer success. The company’s product range includes engines and components for on-highway and off-highway applications, making it a trusted name in the commercial truck industry 3.

Compatibility with Cummins Engines

The Socket Head Cap Screw 4079166 is compatible with several Cummins engine models, including the 6B5.9 Series, B5.9 Series, ISB5.9 Series, and B5.6 CM2670 B152B. This part is designed to secure various engine components, ensuring structural integrity and operational efficiency.

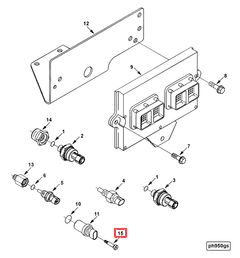

Role in Engine Systems

This part plays a role in various engine systems, including the flywheel assembly, Fuel Control Module, Fuel Drain Connector, Hand Operating Winch, Lifting Fixture, and Engine Control Module. Its primary function is to provide secure fastening, ensuring that components remain firmly in place under operational stresses.

Conclusion

The Socket Head Cap Screw 4079166 by Cummins is a critical component in the maintenance and operation of commercial trucks. Its robust design, ease of installation, and resistance to loosening make it an invaluable part in ensuring the reliability and safety of truck operations. Regular maintenance and proper installation are key to maximizing the performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.