4095442

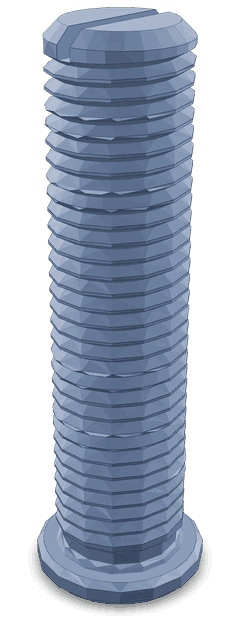

Crosshead Adjusting Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Crosshead Adjusting Screw, part number 4095442, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive industry, produces this screw to enhance the functionality and reliability of engine assemblies. This Cummins part is integral to the efficient operation of heavy-duty engines, playing a role in maintaining the precision and performance of the engine’s moving parts.

Basic Concepts and Functionality

The Crosshead Adjusting Screw operates on the principle of fine-tuning the alignment and clearance between the crosshead and other engine components. This screw allows for the adjustment of the crosshead’s position, which is important for the smooth reciprocation of the piston within the cylinder. By interacting with the crosshead bearing and the connecting rod, the screw ensures that the forces are evenly distributed, reducing wear and tear on the engine components and promoting a balanced operation 1.

Purpose and Role in Truck Operation

The primary purpose of the Crosshead Adjusting Screw in truck operation is to maintain the correct alignment and clearance of the crosshead within the engine. This alignment is vital for the efficient transfer of power from the piston to the crankshaft. Proper adjustment of the crosshead ensures that the engine operates within its designed parameters, contributing to the overall performance and efficiency of the truck. It helps in minimizing friction and wear, which are common issues in high-stress environments typical of heavy-duty truck engines 2.

Key Features

The Crosshead Adjusting Screw is characterized by several key features that enhance its performance. It is typically made from high-strength materials to withstand the rigorous conditions within an engine. The design includes precise threading and a robust construction to ensure durability and reliability. Additionally, the screw may feature anti-corrosion coatings to protect against the harsh chemicals and temperatures found in engine environments 3.

Benefits

Using the Crosshead Adjusting Screw offers several benefits. It contributes to improved engine reliability by ensuring that the crosshead is properly aligned, which reduces the risk of mechanical failure. Enhanced performance is another advantage, as proper alignment leads to more efficient power transfer and reduced energy loss. Over time, the use of this screw can lead to potential cost savings by minimizing the need for frequent repairs and maintenance 4.

Installation Process

Installing the Crosshead Adjusting Screw requires careful attention to detail. The process involves disassembling the engine to access the crosshead, cleaning the area to remove any debris, and then carefully threading the screw into place. It is important to use the correct tools to avoid damaging the screw or the surrounding components. Once installed, the screw should be tightened to the manufacturer’s specified torque settings to ensure proper fit and functionality.

Troubleshooting and Maintenance

Common issues with the Crosshead Adjusting Screw may include improper alignment, which can lead to increased wear on engine components. Troubleshooting steps involve checking the screw’s position and making necessary adjustments. Regular maintenance, such as cleaning and inspecting the screw for signs of wear or corrosion, can help prolong its lifespan and ensure optimal performance. It is also important to follow the manufacturer’s guidelines for periodic checks and adjustments.

Compatibility and Application

The Crosshead Adjusting Screw is designed for use in specific types of engines and truck models. It is commonly applied in heavy-duty diesel engines where precise alignment of the crosshead is critical. The screw’s compatibility with various engine configurations makes it a versatile component in the maintenance and repair of heavy-duty trucks.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the automotive industry, known for its high-quality engine components. With a long history of innovation and a strong reputation for reliability, Cummins is committed to producing parts that meet the demanding requirements of heavy-duty applications. Their expertise in engine technology is reflected in the design and performance of the Crosshead Adjusting Screw.

Crosshead Adjusting Screw (Part 4095442) in Cummins Engines

The Crosshead Adjusting Screw, identified by part number 4095442, is a component in the operation of certain Cummins engines. This part is integral to the engine’s crosshead mechanism, which is responsible for converting the piston’s linear motion into rotational motion at the crankshaft.

Application in Cummins Engines

-

QSK78 Series: The Crosshead Adjusting Screw is utilized in the QSK78 series engines, which are known for their robust design and high performance in various industrial applications. This screw ensures precise alignment and adjustment of the crosshead, which is crucial for maintaining optimal engine efficiency and longevity.

-

CM500 Series: Similarly, in the CM500 series engines, the Crosshead Adjusting Screw plays a role. These engines are typically used in marine and power generation applications, where reliability and durability are paramount. The screw’s function in these engines is to facilitate fine-tuning of the crosshead’s position, ensuring that the engine operates smoothly and efficiently under varying loads and conditions.

Importance of the Crosshead Adjusting Screw

The Crosshead Adjusting Screw is important for maintaining the integrity of the crosshead mechanism. Proper adjustment ensures that the crosshead moves smoothly within its guides, reducing wear and tear on the engine components. This, in turn, helps to prolong the engine’s lifespan and maintain its performance over time.

Installation and Maintenance

When installing or replacing the Crosshead Adjusting Screw, it is crucial to follow the manufacturer’s guidelines to ensure that the screw is properly torqued and aligned. Regular maintenance checks should be performed to verify that the screw remains in good condition and is not causing any undue stress on the crosshead or other engine parts.

Understanding the Role of Part 4095442 Crosshead Adjusting Screw in Engine Systems

The Crosshead Adjusting Screw is a component in the intricate dance of engine mechanics, particularly within the valve train system. This screw plays a role in ensuring the precise operation of the valve mechanism, which is vital for the engine’s performance and efficiency.

Integration with the Cylinder Head and Valve Mechanism

The cylinder head is a critical part of the engine, housing the valves that control the intake and exhaust of gases. The Crosshead Adjusting Screw interfaces directly with the valve crosshead, a component that connects the rocker arm to the valve stem. By adjusting the screw, mechanics can fine-tune the clearance between the rocker arm and the valve, ensuring optimal valve operation. This adjustment is necessary to maintain the engine’s efficiency, as improper clearance can lead to issues such as valve float or increased wear.

Interaction with the Rocker Arm and Lever System

The rocker arm acts as a lever, amplifying the motion from the camshaft to open and close the valves. The Crosshead Adjusting Screw allows for the precise setting of this lever’s action point. By making minute adjustments to the screw, engineers and mechanics can ensure that the rocker arm engages the valve at the correct moment in the engine’s cycle. This timing is important for maximizing engine performance and fuel efficiency.

Ensuring Smooth Cylinder Operation

The cylinder is where the combustion process occurs, and its operation is directly influenced by the timing and efficiency of the valve openings. The Crosshead Adjusting Screw, by ensuring the proper function of the valve train, contributes to the smooth and consistent operation of the cylinder. This, in turn, affects the overall performance of the engine, including its power output and fuel consumption.

Conclusion

In summary, the Crosshead Adjusting Screw is a key component in the valve train system, facilitating the precise operation of the valve mechanism. Its role in adjusting the clearance between the rocker arm and the valve, and ensuring the correct timing of valve operation, is fundamental to the engine’s performance and efficiency. Understanding and correctly utilizing this component is important for any engineer or mechanic working on engine systems.

-

Reif, Konrad Ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Sclar, Deanna. Auto Repair for Dummies: 2nd Edition. For Dummies, 2008.

↩ -

Bennett, Sean, and Ian Andrew Norman. Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.