4096760

Captive Washer Cap Screw

Cummins®

AVAILABLE

6 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4096760 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for heavy-duty truck applications. This component is integral to the assembly and maintenance of various truck systems, ensuring secure and reliable connections. Cummins, a well-established manufacturer in the automotive industry, produces this screw to meet the demanding requirements of heavy-duty vehicles 1.

Basic Concepts of Captive Washer Cap Screws

A captive washer cap screw is a type of fastener that includes an integrated washer, which remains attached to the screw during installation. This design eliminates the need for separate washers, streamlining the installation process and reducing the risk of washer loss. In the automotive industry, these screws are commonly used in applications where vibration and movement are prevalent, ensuring consistent pressure and secure fastening 2.

Purpose of the 4096760 Captive Washer Cap Screw

This Cummins part plays a role in the operation of a truck by providing a reliable fastening solution in areas subjected to high stress and vibration. It is typically used in engine components, chassis assemblies, and other critical areas where secure and durable connections are required. The screw helps maintain the integrity of these connections, contributing to the overall performance and safety of the vehicle 3.

Key Features

The 4096760 features a robust design that includes a high-strength material composition, typically made from alloy steel. This material ensures durability and resistance to wear and corrosion. The screw’s design incorporates a captive washer, which is securely attached to the screw head, simplifying the installation process. Additionally, the screw may have a coated finish to enhance corrosion resistance and improve performance in harsh environments.

Benefits

Using this part offers several advantages. Its integrated washer design simplifies installation, reducing the time and effort required for fastening. The high-strength material ensures durability, providing a reliable connection in demanding applications. The screw’s design also enhances performance by maintaining consistent pressure and reducing the risk of loosening due to vibration.

Installation Process

To install the 4096760, begin by ensuring the mating surfaces are clean and free of debris. Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings, ensuring a secure and proper fit. It is important to follow the recommended installation sequence and use the appropriate tools to avoid damage to the screw or surrounding components.

Troubleshooting Common Issues

Common issues with captive washer cap screws include loosening due to vibration and corrosion. To address these problems, regularly inspect the screws for signs of wear or corrosion. If loosening is detected, re-tighten the screw to the specified torque settings. In cases of corrosion, consider replacing the screw with a new one to ensure continued performance and reliability.

Maintenance Tips

Regular maintenance of the 4096760 involves periodic inspection and re-tightening as needed. Ensure that the screw and surrounding components are free of dirt and debris, which can contribute to corrosion. Applying a corrosion-resistant coating or lubricant can also help maintain the screw’s performance and extend its service life.

Compatibility and Applications

The 4096760 is designed for use in Cummins engines and is compatible with various heavy-duty truck applications. It is commonly used in engine components, chassis assemblies, and other critical areas where secure and durable connections are required. The screw’s versatile design makes it suitable for a wide range of applications within the automotive industry.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted provider of automotive components, particularly for heavy-duty trucks. The company’s commitment to innovation and quality ensures that its products, including the 4096760, meet the highest standards of performance and reliability.

Application in Cummins Engines

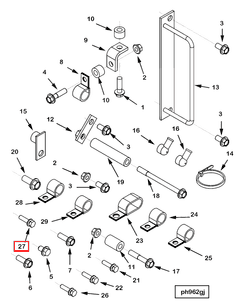

QSB4.5 CM850 (CM2850)

In the QSB4.5 CM850 (CM2850) engine, the Captive Washer Cap Screw is utilized in several key areas. It plays a vital role in fastening components that require precise alignment and secure attachment. This includes securing the engine block, cylinder heads, and various other sub-assemblies. The cap screw’s design ensures that the washer remains captive, preventing it from dislodging during operation, which is crucial for maintaining the engine’s structural integrity.

QSB4.5 CM850 (CM2850) Group

When considering the QSB4.5 CM850 (CM2850) group of engines, the Captive Washer Cap Screw is consistently used across different models within this series. This uniformity in application highlights the importance of this component in ensuring the reliability and durability of the engines. The cap screw’s role in these engines is to provide a robust and dependable fastening solution, which is essential for the overall performance and longevity of the engine.

Role of Part 4096760 in Engine Systems

The 4096760 is integral to the secure assembly and operation of various engine components. Its application ensures the stability and integrity of the following systems:

Engine Control Module (ECM) Mounting

In the mounting of the Engine Control Module (ECM), the Captive Washer Cap Screw plays a significant role. It provides the necessary tension and security to keep the ECM firmly in place. This is essential for the ECM to function correctly, as any movement can lead to inaccurate readings and improper engine management.

Housing and Flywheel Mounting

When it comes to housing and flywheel mounting, the Captive Washer Cap Screw ensures that these components remain securely attached to the engine block. This is particularly important for the flywheel, as it is subject to significant rotational forces. The screw’s design helps in distributing these forces evenly, preventing any potential damage or misalignment.

Engine Control Module (ECM) and Plumbing Connections

For the ECM and its associated plumbing connections, the Captive Washer Cap Screw is used to secure various sensors and connectors. This ensures that all connections remain tight and secure, which is vital for the accurate transmission of data and fluids. Any loose connection can lead to system failures or leaks, which can be detrimental to engine performance.

Turbocharger and Turbocharger Kit Integration

In the context of turbochargers and turbocharger kits, the Captive Washer Cap Screw is employed to secure the turbocharger to the engine. This is crucial for maintaining the turbocharger’s alignment and operational efficiency. The screw’s captive washer feature prevents loss of the washer during installation or maintenance, ensuring a consistent and reliable connection.

Conclusion

The 4096760 Captive Washer Cap Screw is a fundamental component in the assembly and maintenance of various engine systems, contributing to their stability, efficiency, and longevity. Its robust design, high-strength material, and integrated washer feature make it an essential part for securing critical engine components in heavy-duty truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.