4098534

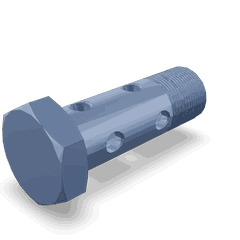

Banjo Connector Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4098534 Banjo Connector Screw is a specialized component used in commercial trucks. This fitting is designed to connect hoses to various fluid lines, including hydraulic and fuel systems, ensuring secure and leak-proof connections that are vital for the efficient operation of a truck’s fluid systems 1.

Basic Concepts and Functionality

Banjo connector screws operate on a simple yet effective principle. They consist of a bolt with a flat, circular head that has a drilled hole through it. This head is clamped against a gasket or O-ring, which creates a seal when tightened. The hose is then connected to the fitting via the drilled hole, allowing fluid to pass through while maintaining a secure connection. This mechanism is essential for maintaining the integrity of fluid systems, ensuring that there are no leaks and that the system operates efficiently 2.

Purpose and Role in Truck Operation

In the context of a commercial truck, the 4098534 Banjo Connector Screw plays a role in ensuring secure and leak-proof connections in various fluid systems such as fuel, hydraulic, and brake systems. Its purpose is to provide a reliable connection point that can withstand the pressures and conditions present in these systems, thereby contributing to the overall performance and safety of the truck 3.

Key Features

The 4098534 Banjo Connector Screw is designed with several key features that enhance its durability and sealing efficiency. It is typically made from high-strength materials to resist corrosion and wear. The design includes precise threading and a robust sealing mechanism that ensures a tight fit. Additionally, the screw may feature unique attributes such as a corrosion-resistant coating or specialized gasket materials that differentiate it from other similar parts.

Benefits

Using the 4098534 Banjo Connector Screw offers several benefits. It provides improved reliability in fluid connections, which is essential for the safe and efficient operation of a truck. The design allows for ease of installation, reducing downtime during maintenance. Furthermore, its robust construction and sealing mechanism contribute to lower maintenance requirements and enhanced safety, as it helps prevent leaks that could lead to system failures.

Installation and Usage

Proper installation of the 4098534 Banjo Connector Screw is key to ensuring a secure and effective connection. It is recommended to use the appropriate tools to tighten the screw to the manufacturer’s specified torque settings. This ensures that the connection is secure without over-tightening, which could damage the fitting or the hose. Following best practices for installation, such as ensuring the gasket or O-ring is in good condition and properly seated, is also important for the longevity of the connection.

Troubleshooting and Maintenance

Common issues with banjo connector screws may include leaks, corrosion, or wear on the fitting or gasket. Troubleshooting steps may involve checking the torque of the connection, inspecting the gasket for damage, and ensuring that the hose is properly seated. Regular maintenance, such as inspecting the fitting for signs of wear or corrosion and replacing the gasket as needed, can help ensure the longevity and optimal performance of the 4098534 Banjo Connector Screw. If signs of failure are present, such as persistent leaks or visible damage, replacement of the fitting may be necessary.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company is committed to providing reliable and efficient components that meet the demanding requirements of commercial vehicles, ensuring that their products contribute to the safety, performance, and longevity of the trucks they are installed in.

Cummins Banjo Connector Screw 4098534 in Engine Applications

The Cummins 4098534 Banjo Connector Screw is a critical component in the fuel and hydraulic systems of various Cummins engines. This part is essential for maintaining the integrity of connections in high-pressure systems, ensuring that there are no leaks or failures under operational stress.

ISZ13 CM2150 Z105

In the ISZ13 CM2150 Z105 engine, the 4098534 Banjo Connector Screw is utilized in the fuel delivery system. Its role is to secure the banjo fitting to the fuel line, preventing any disconnections that could lead to fuel leaks or engine performance issues.

QSK60 CM850 MCRS and QSK95 CM2350 K111/K113

For the QSK60 CM850 MCRS engine, the 4098534 Banjo Connector Screw is integral to the hydraulic system, ensuring that the connections in the hydraulic lines remain tight and secure. This is particularly important in heavy-duty applications where hydraulic pressure is critical for the operation of various engine components.

Similarly, in the QSK95 CM2350 K111 and K113 engines, the 4098534 Banjo Connector Screw is used in both fuel and hydraulic systems. Its application in these engines ensures that the connections are robust and can withstand the high pressures and stresses encountered in these systems. This part is crucial for maintaining the operational efficiency and safety of the engines.

Role of Part 4098534 Banjo Connector Screw in Engine Systems

The 4098534 Banjo Connector Screw is an integral component in the efficient operation of various engine systems. Its primary function is to ensure secure and leak-free connections in fuel and oil plumbing systems.

In the fuel plumbing system, this banjo connector screw is used to connect fuel lines to the fuel injectors and other critical components. It plays a significant role in maintaining the integrity of the fuel delivery system, ensuring that fuel is delivered under precise pressure and without leaks. This is essential for the consistent performance of the engine, particularly in high-performance applications where fuel delivery precision can significantly impact engine output and efficiency.

Within the cylinder head and camshaft assemblies, the banjo connector screw is often employed to connect oil passages. This ensures that lubrication is efficiently distributed to moving parts such as the camshaft, connecting rod and piston assemblies, and rocker arms. Proper lubrication is vital for reducing friction and wear, thereby enhancing the longevity and reliability of these components.

In the hose kit and various plumbing applications, the banjo connector screw provides a robust connection point that can withstand the pressures and vibrations inherent in engine operation. This is particularly important in systems where fluid dynamics play a key role, such as in the fuel drain systems where efficient and secure connections prevent contamination and ensure system cleanliness.

Overall, the banjo connector screw is a small yet significant part that contributes to the seamless operation of complex engine systems, playing a key role in maintaining performance, efficiency, and reliability.

Conclusion

The 4098534 Banjo Connector Screw by Cummins is a vital component in the fluid systems of commercial trucks and engines. Its design ensures secure, leak-proof connections that are essential for the efficient and safe operation of these systems. Proper installation, regular maintenance, and timely replacement when necessary are crucial for maintaining the performance and reliability of the truck or engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.