This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

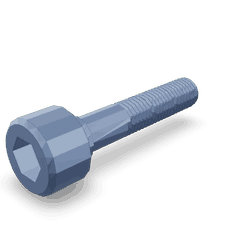

The Socket Head Cap Screw, Part #4302676, manufactured by Cummins, is a specialized fastener designed for use in commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of components that ensure the reliability and efficiency of heavy-duty vehicles. This particular screw is integral to various assemblies within commercial trucks, contributing to the overall performance and durability of the vehicle.

Basic Concepts of Socket Head Cap Screws

Socket Head Cap Screws are a type of fastener characterized by a hexagonal socket in the head, allowing for torque application using a hex key. These screws are commonly used in mechanical assemblies where a flush or countersunk finish is required. They provide a secure and strong connection, making them suitable for applications that demand high tensile strength and resistance to loosening 1.

Purpose of Socket Head Cap Screw Part #4302676 in Truck Operation

The Socket Head Cap Screw Part #4302676 plays a specific role in the operation and maintenance of commercial trucks. It is utilized in critical assemblies where secure fastening is necessary to maintain structural integrity and functionality. This screw ensures that components remain firmly in place, contributing to the safe and efficient operation of the truck. Its design allows for easy installation and removal, facilitating maintenance procedures 2.

Key Features of Socket Head Cap Screw Part #4302676

The Socket Head Cap Screw Part #4302676 is engineered with several key features that enhance its performance. It is constructed from high-quality materials, ensuring durability and resistance to corrosion. The screw features precise threading that provides a strong grip and secure fastening. The hexagonal socket head allows for efficient torque application, reducing the risk of cam-out and ensuring accurate tightening. Additionally, the design of the screw head minimizes the risk of loosening due to vibration, a common issue in heavy-duty truck applications.

Benefits of Using Socket Head Cap Screw Part #4302676

The Socket Head Cap Screw Part #4302676 offers several advantages. Its robust construction and high-quality materials contribute to its durability, making it suitable for demanding applications. The precise threading ensures a secure fit, while the hexagonal socket head allows for easy and accurate installation. Additionally, the screw’s resistance to loosening enhances the reliability of the assemblies it is used in, reducing the need for frequent maintenance.

Installation and Usage Guidelines

To ensure optimal performance and longevity, the Socket Head Cap Screw Part #4302676 should be installed following specific guidelines. Begin by cleaning the installation area to remove any debris or contaminants. Use a hex key to drive the screw into the designated hole, applying even pressure to avoid cross-threading. Tighten the screw to the recommended torque specification to ensure a secure fit without over-tightening, which could damage the screw or the surrounding components.

Troubleshooting Common Issues

Common issues with Socket Head Cap Screws include loosening due to vibration and corrosion. To address these problems, regularly inspect the screws for signs of wear or damage. If a screw appears loose, remove it and clean the threads before re-installing. Applying a thread locker can help prevent loosening. In cases of corrosion, replace the screw to maintain the integrity of the assembly.

Maintenance Tips

Regular maintenance of Socket Head Cap Screws is essential to prevent failure and extend their service life. Inspect screws during routine maintenance checks for signs of wear, corrosion, or loosening. Clean the screws and surrounding areas to remove any buildup that could affect performance. Applying a corrosion-resistant coating can further protect the screws from environmental factors.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications.

Socket Head Cap Screw 4302676 in Cummins Engines

The Socket Head Cap Screw 4302676, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the assembly and maintenance of the engines, ensuring secure fastening and structural integrity.

QST30 and CM2350 Engines

In the QST30 and CM2350 engines, the Socket Head Cap Screw 4302676 is utilized in various applications where robust fastening is required. These engines, known for their reliability and performance, benefit from the precision and strength provided by this screw. The screw’s design ensures that it can withstand the operational stresses and environmental conditions these engines encounter.

T101 Engine

The T101 engine also incorporates the Socket Head Cap Screw 4302676 in its construction. This engine, designed for heavy-duty applications, relies on the screw’s ability to maintain tight connections under high load and pressure. The use of this screw in the T101 engine highlights its importance in achieving the engine’s performance and durability standards.

Grouping of Engines

The Socket Head Cap Screw 4302676 is a common component across the QST30, CM2350, and T101 engines, indicating its versatility and critical role in Cummins’ engine designs. Its application in these engines underscores the importance of high-quality fasteners in ensuring the engines’ operational efficiency and longevity.

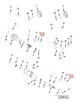

Role of Part 4302676 Socket Head Cap Screw in Engine Systems

The part 4302676 Socket Head Cap Screw is integral to the assembly and functionality of various engine components. In the context of the drive system, this screw is often used to secure components that require precise alignment and robust fastening. Its design allows for efficient torque application, ensuring that parts remain firmly in place under the dynamic conditions of engine operation.

Within the fuel pump assembly, the Socket Head Cap Screw plays a significant role in maintaining the integrity of the pump housing. It is employed to fasten the fuel pump to its support structure, ensuring that the pump operates within its designed parameters. This secure attachment is vital for the consistent delivery of fuel to the engine, contributing to overall performance and reliability.

The fuel pump support system also benefits from the use of the Socket Head Cap Screw. This component is typically used to attach the support brackets and mounts that hold the fuel pump in place. The screw’s hexagonal socket head allows for easy installation and removal using a socket wrench, facilitating maintenance and repair procedures.

Conclusion

In summary, the part 4302676 Socket Head Cap Screw is a fundamental fastener in engine systems, providing the necessary strength and stability to critical components such as the drive, fuel pump, and fuel pump support. Its reliable performance ensures that these components function as intended, contributing to the engine’s efficiency and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.