This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

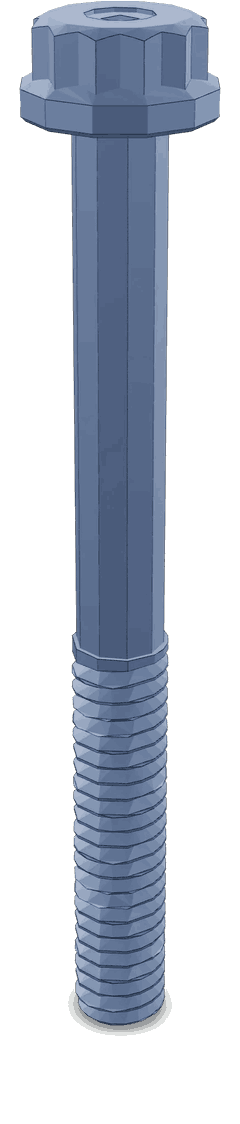

The Hexagon Flange Head Cap Screw, part number 4313208, manufactured by Cummins, is a vital component in the maintenance and repair of commercial trucks. This screw is designed to provide secure fastening in various truck applications, ensuring the integrity and reliability of truck components. Understanding the role and functionality of this specific part is essential for maintaining the performance and longevity of commercial vehicles.

Basic Concepts and Functionality

Hexagon Flange Head Cap Screws are engineered to offer robust fastening solutions in mechanical systems. These screws feature a hexagonal head with a flange, which provides a larger surface area for torque application, reducing the risk of stripping and enhancing the screw’s holding power. The design allows for easy installation and removal using standard tools, making them a preferred choice in various industrial applications. The screw’s threading engages with the material it is fastened into, creating a strong and secure connection that can withstand significant stress and vibration 1.

Purpose and Role in Truck Operation

This Cummins part plays a specific role in the operation of commercial trucks by securing critical components and assemblies. Its design ensures that parts remain firmly in place, even under the demanding conditions typical of truck operation. This screw is often used in applications where vibration and dynamic loads are present, such as in engine mounts, chassis components, and various structural attachments. By providing a reliable fastening solution, it contributes to the overall functionality and safety of the truck 2.

Key Features

The 4313208 boasts several key features that enhance its performance. Its hexagonal flange head design allows for efficient torque application, reducing the likelihood of cam-out during installation. The screw is typically made from high-strength materials, such as alloy steel, which provides excellent durability and resistance to corrosion. Additionally, the flange head offers increased surface contact, which helps distribute load more evenly and reduces the risk of loosening over time 3.

Benefits

Using this part in truck maintenance and repair offers several advantages. Its robust construction and design contribute to enhanced durability, making it suitable for long-term use in demanding environments. The screw’s resistance to loosening ensures that fastened components remain secure, even under vibration and dynamic loads. Furthermore, the ease of installation, thanks to its hexagonal head, allows for quick and efficient fastening, reducing downtime during maintenance procedures.

Installation and Usage Guidelines

Proper installation of the 4313208 is crucial for ensuring secure fastening. Begin by selecting the appropriate drill bit to create a pilot hole, which helps guide the screw and prevents splitting of the material. Use a torque wrench to apply the recommended torque settings, ensuring that the screw is tightened to the manufacturer’s specifications. This prevents over-tightening, which can lead to damage, and under-tightening, which can compromise the fastening integrity. Always use the correct tools and follow best practices to achieve a secure and lasting connection.

Troubleshooting and Maintenance

Common issues with Hexagon Flange Head Cap Screws include loosening due to vibration and corrosion caused by exposure to harsh environments. To troubleshoot these problems, regularly inspect screws for signs of wear or damage. If corrosion is present, consider using screws made from corrosion-resistant materials or applying a protective coating. To prevent loosening, ensure that screws are tightened to the proper torque specifications and consider using lock washers or thread-locking compounds. Regular maintenance and inspection will help prolong the lifespan of the screw and ensure optimal performance.

Compatibility and Applications

The 4313208 is commonly used in a variety of applications within commercial trucks. It is compatible with different truck models and components, making it a versatile choice for truck maintenance. Typical applications include fastening engine components, chassis parts, and structural attachments. Ensuring compatibility with specific truck models and components is important for achieving the best performance and reliability.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive and commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation among truck operators and maintenance professionals. The company’s extensive product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial truck applications. Cummins’ dedication to excellence ensures that their products, including the 4313208, deliver consistent performance and durability.

Hexagon Flange Head Cap Screw Part 4313208 in Cummins Engines

The Cummins part number 4313208, a Hexagon Flange Head Cap Screw, is a critical component in the assembly and maintenance of several Cummins engine models. This part is specifically designed to provide a secure fastening solution, ensuring that various engine components remain tightly connected under operational stress.

Application in QSK95 Engines

In the QSK95 series, the Hexagon Flange Head Cap Screw is utilized in multiple configurations, including the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as marine and industrial settings. The part 4313208 plays a vital role in maintaining the integrity of the engine’s structure by securing different parts together, ensuring smooth operation and longevity.

Common Usage Across Engine Models

While the specific applications may vary, the Hexagon Flange Head Cap Screw is a common component across various Cummins engine models. Its design allows for easy installation and removal, which is crucial during routine maintenance and repairs. The screw’s flange head provides a larger surface area for torque application, which is essential for achieving the necessary clamping force without damaging the engine components.

Importance in Engine Assembly

The precision engineering of the Hexagon Flange Head Cap Screw ensures that it fits seamlessly into the engine’s design. Its use in high-stress areas means that it must meet stringent quality standards to withstand the operational demands of the engine. The screw’s material and finish are selected to resist corrosion and wear, further enhancing the engine’s durability and performance.

Hexagon Flange Head Cap Screw (Part 4313208) Component Usage

The Hexagon Flange Head Cap Screw, identified by part number 4313208, is an essential fastening component utilized in various engine systems to ensure secure assembly and reliable operation. Its application spans across multiple components, each playing a distinct role in the overall functionality of the engine.

Aftercooler

In the aftercooler system, the Hexagon Flange Head Cap Screw is employed to fasten the aftercooler to its mounting brackets. This secure attachment is vital for maintaining the structural integrity of the aftercooler, which is responsible for cooling the compressed air from the turbocharger before it enters the engine’s combustion chambers. Proper fastening ensures efficient heat exchange and prevents leaks that could compromise engine performance.

Cover

The cover components of an engine, which may include valve covers, timing covers, or inspection covers, often require robust fastening solutions. The Hexagon Flange Head Cap Screw provides the necessary strength and stability to keep these covers securely in place. This is important for protecting internal engine components from contaminants and ensuring that no fluids or gases escape, which could lead to inefficient operation or damage.

Front Gear

In gear-driven systems, such as those found in front-mounted accessories or timing systems, the Hexagon Flange Head Cap Screw is used to attach gear housings or brackets. This ensures that the gears remain aligned and operate smoothly, which is essential for the synchronized function of engine accessories and the precise timing of valve operations.

Drive

For components that involve mechanical drives, such as belt-driven accessories or chain-driven systems, the Hexagon Flange Head Cap Screw plays a role in securing drive pulleys, sprockets, or mounting brackets. This secure attachment is necessary to maintain the tension and alignment of drive systems, ensuring consistent power transmission and reducing the risk of belt slippage or chain derailment.

Fuel Pump

In fuel pump assemblies, the Hexagon Flange Head Cap Screw is utilized to fasten the pump housing or mounting brackets. This secure attachment is crucial for maintaining the structural integrity of the fuel pump, ensuring it can withstand the pressures and vibrations associated with fuel delivery. Proper fastening also helps in sealing the fuel system, preventing leaks that could pose safety hazards or affect engine performance.

Primer

For engines equipped with primer systems, the Hexagon Flange Head Cap Screw is used to secure the primer pump or its associated components. This ensures that the primer system remains intact and functional, aiding in the easy starting of the engine by providing an initial dose of fuel to the combustion chambers.

Engine Lubricating Pump

In the engine lubricating system, the Hexagon Flange Head Cap Screw is employed to fasten the lubricating pump housing or its mounting brackets. This secure attachment is important for maintaining the structural integrity of the pump, ensuring it can effectively circulate lubricant throughout the engine to reduce friction and wear on moving parts.

Fuel

While the term “fuel” is broad, in the context of fuel system components such as fuel lines, filters, or injectors, the Hexagon Flange Head Cap Screw may be used to secure these elements in place. This ensures that the fuel system remains intact and leak-free, which is essential for maintaining the correct fuel pressure and delivery to the engine’s combustion chambers.

Conclusion

The 4313208 Hexagon Flange Head Cap Screw is a critical component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, ease of installation, and resistance to loosening make it an invaluable part for securing various engine components. Understanding its features, benefits, and proper installation techniques is essential for ensuring the longevity and reliability of truck and engine systems.

-

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩ -

Brown Jr, Andrew. Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles. National Academy of Sciences, 2010.

↩ -

Garrett, TK, K Newton, and W Steeds. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.