This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

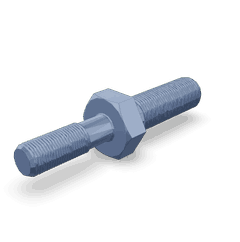

The 4319185 Studded Hexagon Cap Screw is a specialized fastener produced by Cummins, a well-known manufacturer in the commercial truck industry. This screw is designed for use in commercial trucks, where it plays a role in securing various components and assemblies. Its robust design and reliable performance make it a valuable component in the maintenance and operation of heavy-duty vehicles.

Basic Concepts of Studded Hexagon Cap Screws

A studded hexagon cap screw is a type of fastener that features a hexagonal head and a threaded shank, allowing it to be driven using a wrench or socket. These screws are commonly used in mechanical assemblies to secure components together under tension. The hexagonal head provides a secure grip for tools, ensuring that the screw can be tightened or loosened with precision. In applications where high strength and durability are required, studded hexagon cap screws are often preferred due to their ability to withstand significant loads and stresses 1.

Purpose of the 4319185 Studded Hexagon Cap Screw

In the context of commercial trucks, the 4319185 Studded Hexagon Cap Screw serves to secure critical components and assemblies. It is often used in engine compartments, chassis structures, and other areas where reliable fastening is necessary. By providing a strong and durable connection, this screw helps to ensure the integrity and safety of the truck’s structure and components.

Key Features

The 4319185 Studded Hexagon Cap Screw is characterized by several key features that enhance its performance. Its design includes a hexagonal head for easy tool engagement and a threaded shank that allows for secure fastening. The screw is made from high-quality materials, typically steel alloys, which provide excellent strength and corrosion resistance. Additionally, the screw may feature a studded design, which can offer increased load-bearing capacity and resistance to loosening under vibration 2.

Benefits

Using the 4319185 Studded Hexagon Cap Screw offers several benefits. Its durable construction ensures long-lasting performance, even in demanding environments. The screw’s design allows for easy installation and removal, reducing maintenance time. Furthermore, its high strength and resistance to corrosion make it a reliable choice for commercial truck applications, where components are subjected to significant stress and exposure to the elements.

Installation Process

To install the 4319185 Studded Hexagon Cap Screw, follow these steps to ensure optimal performance and longevity:

- Ensure the mating surfaces are clean and free of debris.

- Align the screw with the designated hole or thread.

- Use a wrench or socket to tighten the screw gradually, applying even pressure to avoid cross-threading.

- Tighten the screw to the manufacturer’s recommended torque specification to ensure proper tension without over-tightening.

Troubleshooting Common Issues

Common issues with the 4319185 Studded Hexagon Cap Screw may include loosening under vibration, corrosion, or difficulty in installation. To address these problems:

- Regularly inspect the screw for signs of loosening or corrosion.

- Apply a thread locker or anti-seize compound to prevent loosening and facilitate easier installation.

- Replace any corroded or damaged screws promptly to maintain the integrity of the assembly.

Maintenance Tips

To prolong the service life and maintain the efficiency of the 4319185 Studded Hexagon Cap Screw, consider the following maintenance tips:

- Perform regular inspections to check for signs of wear, corrosion, or loosening.

- Clean the screw and surrounding area to remove dirt and debris that could contribute to corrosion.

- Lubricate the threads with a suitable lubricant to reduce friction and wear during installation and operation.

Cummins: Manufacturer Overview

Cummins is a reputable manufacturer with a long-standing history in the commercial truck industry. Known for its commitment to quality and innovation, Cummins produces a wide range of components and systems designed to enhance the performance and reliability of commercial vehicles. The company’s dedication to excellence is reflected in its products, including the 4319185 Studded Hexagon Cap Screw, which is engineered to meet the rigorous demands of heavy-duty applications 3.

Integration of Studded Hexagon Cap Screw in Cummins Engines

The Studded Hexagon Cap Screw, part number 4319185, manufactured by Cummins, is a critical component in various engine models. This screw is integral to the assembly and maintenance of several Cummins engines, ensuring structural integrity and operational efficiency.

ISG12 G CMOH6.0 G111 and ISM CM570

In the ISG12 G CMOH6.0 G111 and ISM CM570 engines, the 4319185 screw is used in multiple applications, including securing various engine components and ensuring the alignment of parts during assembly. Its robust design provides the necessary strength to withstand the operational stresses these engines endure.

ISM11 CM876 SN, X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, and X13 CM2670 X122B

For the ISM11 CM876 SN, X11 CM2670 X126B, X12 CM2670 X121B, X12N CMMDG1 X143B, and X13 CM2670 X122B engines, the 4319185 screw is similarly essential. It is used in the fastening of critical engine parts, ensuring that components remain securely in place under high-stress conditions. This screw’s studded design provides an additional layer of security, preventing loosening due to vibrations and thermal expansion.

The use of the 4319185 screw across these engines highlights its versatility and importance in maintaining the structural integrity of the engine assemblies. Its application in these models underscores Cummins’ commitment to quality and reliability in their engine components.

Role of Part 4319185 Studded Hexagon Cap Screw in Engine Systems

Compressor Air Inlet Arrangement

In the compressor air inlet arrangement, the 4319185 Studded Hexagon Cap Screw is instrumental in securing components that direct and regulate the airflow into the compressor. This screw ensures that the inlet components remain firmly in place, maintaining the integrity of the air intake system. Proper fastening is essential to prevent any misalignment or loosening that could disrupt the airflow, leading to inefficiencies in the compressor’s performance.

Oil Fill Arrangement

Within the oil fill arrangement, the 4319185 Studded Hexagon Cap Screw plays a significant role in securing the oil fill cap and associated components. This ensures a tight seal, preventing oil leaks and maintaining the proper oil level within the engine. The screw’s robust design helps withstand the pressures and vibrations inherent in engine operation, ensuring that the oil fill system remains reliable and efficient.

Conclusion

The 4319185 Studded Hexagon Cap Screw is a vital component in the maintenance and operation of commercial trucks, particularly in Cummins engines. Its robust design, high strength, and resistance to corrosion make it an essential fastener for securing critical components and assemblies. Proper installation, regular maintenance, and timely replacement of this part ensure the continued reliability and efficiency of heavy-duty vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.