This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

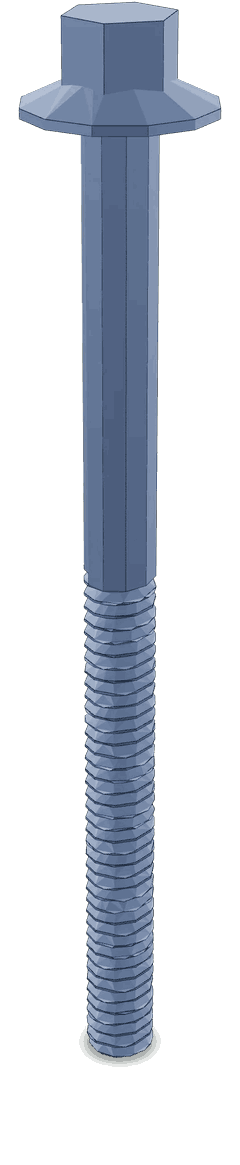

The Fracture Resistant Screw (Part #4325052) by Cummins is a specialized component designed to enhance the durability and reliability of commercial trucks. This screw is integral to maintaining the structural integrity of various truck components, ensuring they withstand the rigors of heavy-duty operations.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are engineered to resist breaking under stress, which is particularly important in mechanical applications where components are subject to significant loads and vibrations. These screws are typically made from high-strength materials and are designed with specific geometries to distribute stress more evenly, reducing the likelihood of failure 1.

Purpose of the 4325052 Fracture Resistant Screw

The 4325052 Fracture Resistant Screw plays a role in securing critical components within a truck’s structure. It is commonly used in applications where traditional screws might fail due to the high stress and dynamic loads experienced during operation. This screw ensures that components remain firmly attached, contributing to the overall safety and performance of the vehicle.

Key Features

The 4325052 Fracture Resistant Screw is constructed from a high-strength alloy, which provides superior resistance to fracture. Its design includes a threaded shaft that allows for secure fastening, and a head designed to distribute force evenly. Additionally, the screw features a corrosion-resistant coating, enhancing its durability in various environmental conditions 2.

Benefits

Using the 4325052 Fracture Resistant Screw offers several advantages. It provides improved reliability by reducing the risk of screw failure under stress. This enhances the safety of the truck by ensuring that critical components remain securely attached. Furthermore, the screw’s durable construction contributes to the longevity of truck components, reducing the need for frequent replacements 3.

Installation Process

Installing the 4325052 Fracture Resistant Screw requires careful attention to ensure proper fitting. Begin by cleaning the installation site to remove any debris or corrosion. Use a torque wrench to install the screw, applying the manufacturer’s recommended torque specifications to avoid over-tightening, which could damage the screw or the component it is securing. Ensure that the screw is aligned correctly with the fastening point to distribute stress evenly.

Troubleshooting and Maintenance

Common issues with the 4325052 Fracture Resistant Screw may include loosening over time due to vibrations or corrosion. Regular inspections should be conducted to check for signs of wear or damage. If corrosion is detected, cleaning the screw and applying a protective coating can help prolong its service life. In cases where the screw shows signs of loosening, re-torqueing to the manufacturer’s specifications is recommended.

Comparative Analysis

When compared to standard screws, the 4325052 Fracture Resistant Screw offers enhanced durability and resistance to fracture. In scenarios where components are subject to high stress and dynamic loads, fracture resistant screws are preferred for their ability to maintain structural integrity and reduce the risk of failure.

Real-World Applications

The 4325052 Fracture Resistant Screw is utilized in various commercial truck models and components. It is commonly found in applications such as securing engine mounts, transmission components, and chassis parts. Its versatility and effectiveness make it a valuable component in ensuring the reliability and safety of commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and aftermarket parts. With a history of innovation and a commitment to quality, Cummins serves customers in over 190 countries and territories, providing reliable and efficient power solutions for various industries.

Fracture Resistant Screw 4325052 in Cummins Engines

The Fracture Resistant Screw 4325052, manufactured by Cummins, is a critical component in several engine models. This screw is designed to withstand high stress and prevent fractures under operational conditions, ensuring the longevity and reliability of the engine.

ISV (Nissan) Engines

In the ISV (Nissan) engines, the Fracture Resistant Screw 4325052 plays a vital role in maintaining structural integrity. This screw is strategically placed in areas where it is subjected to significant mechanical stress. Its design ensures that it can endure the rigors of continuous operation without compromising the engine’s performance or safety.

The integration of this screw in ISV engines highlights Cummins’ commitment to quality and durability. By using a fracture-resistant material, Cummins ensures that the screw can handle the demanding conditions of engine operation, thereby reducing the risk of failure and extending the engine’s operational life.

This screw is essential in maintaining the alignment and stability of various engine components, ensuring that the engine operates smoothly and efficiently. Its application in ISV engines underscores the importance of using high-quality, reliable parts in engine design and manufacturing.

Role of Part 4325052 Fracture Resistant Screw in Engine Systems

The 4325052 Fracture Resistant Screw is an essential component in ensuring the structural integrity and reliable operation of various engine systems. Its application spans across multiple components, contributing to the overall performance and durability of the engine.

Camshaft Assembly

In the camshaft assembly, the 4325052 screw is utilized to secure the camshaft to the engine block or cylinder head. This ensures that the camshaft remains in precise alignment with the valve train components, which is vital for the accurate timing of valve operations. The fracture-resistant properties of the screw are particularly important here, as camshafts are subject to significant rotational forces and vibrations.

Hardware Kit Integration

When included in a hardware kit, the 4325052 screw plays a role in fastening various engine components together. Whether it’s securing brackets, mounts, or other ancillary parts, the screw’s resistance to fractures ensures long-term reliability, reducing the need for frequent replacements or adjustments.

Cylinder Head and Block

In the cylinder head and block, these screws are often used to secure critical components such as sensors, fuel injectors, and other attachments. The robust nature of the 4325052 screw ensures that these components remain firmly in place, even under the extreme conditions of high temperatures and pressures within the engine compartment.

Fuel Injector Mounting

For fuel injectors, the 4325052 screw is instrumental in maintaining a secure fit within the cylinder head. This is important for ensuring that fuel delivery is consistent and precise, directly impacting the engine’s performance and fuel efficiency. The fracture resistance of the screw helps in withstanding the repetitive stress from engine vibrations.

Long Block Kit Applications

In a long block kit, which typically includes the engine block, crankshaft, pistons, and often the camshaft, the 4325052 screw is used in various mounting and securing applications. Its durability ensures that the long block remains intact and functions smoothly over its operational life.

Upper Engine Gasket Kit

When dealing with an upper engine gasket kit, these screws are often employed to secure the cylinder head to the engine block. This is a high-stress area where maintaining a tight seal is essential to prevent coolant or oil leaks. The fracture-resistant characteristic of the 4325052 screw is beneficial in this application, ensuring that the seal remains intact under varying engine conditions.

Performance Enhancements

In performance-oriented engine builds, the 4325052 screw is favored for its ability to withstand higher stress levels without failing. Whether it’s for aftermarket camshafts, high-flow cylinder heads, or upgraded fuel injectors, the reliability of this screw contributes to the enhanced performance and longevity of the engine.

Conclusion

The 4325052 Fracture Resistant Screw by Cummins is a critical component in enhancing the durability and reliability of commercial trucks and engines. Its high-strength alloy construction, corrosion-resistant coating, and fracture-resistant design make it suitable for various high-stress applications. Proper installation, regular maintenance, and understanding its role in engine systems are essential for maximizing its benefits and ensuring the longevity of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.