4325147

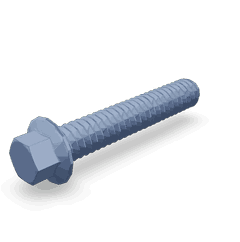

Fracture Resistant Screw

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Fracture Resistant Screw 4325147 is a specialized component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This screw is designed for use in commercial trucks, where it plays a role in ensuring the reliability and durability of various mechanical systems.

Basic Concepts of Fracture Resistant Screws

Fracture resistant screws are engineered to withstand significant mechanical stress without breaking. They are typically used in applications where standard screws might fail under high stress or in harsh environments. These screws are made from materials and designed with features that enhance their resistance to fractures, making them suitable for demanding mechanical applications 1.

Purpose of the 4325147 Fracture Resistant Screw

The 4325147 Fracture Resistant Screw is utilized in commercial trucks to secure components that are subject to high stress and vibration. It is commonly employed in engine assemblies, transmission systems, and other critical areas where the failure of a screw could lead to significant mechanical issues. Its role is to provide a secure and lasting connection, ensuring the integrity of the truck’s mechanical systems.

Key Features

The 4325147 Fracture Resistant Screw boasts several key features that enhance its performance and durability. It is constructed from a high-strength alloy, which provides superior resistance to mechanical stress. The screw’s design includes a threaded body that ensures a tight and secure fit, and it may also feature a special coating to protect against corrosion and wear. These attributes contribute to its reliability in demanding applications 2.

Benefits

Using the 4325147 Fracture Resistant Screw offers several advantages. Its high-strength material composition and design elements contribute to increased durability and resistance to mechanical stress. This screw is particularly beneficial in harsh operating conditions, where standard screws might fail. Its longevity and reliability help reduce the need for frequent replacements, contributing to lower maintenance costs and increased uptime for commercial trucks.

Installation Considerations

Proper installation of the 4325147 Fracture Resistant Screw is vital to ensure optimal performance and longevity. It is recommended to use the correct torque specifications during installation to avoid over-tightening, which can lead to screw failure, or under-tightening, which can result in a loose connection. Additionally, ensuring that the mating surfaces are clean and free from debris will help achieve a secure fit.

Troubleshooting Common Issues

Typical problems with the 4325147 Fracture Resistant Screw may include loosening over time due to vibration or corrosion. If a screw appears loose, it should be re-tightened to the manufacturer’s specified torque. Corrosion can be addressed by cleaning the affected area and applying a protective coating. In cases where a screw has fractured, it should be replaced immediately to prevent further mechanical issues.

Maintenance Tips

Regular maintenance of the 4325147 Fracture Resistant Screw can prolong its service life and ensure continued reliable performance. This includes periodic checks for tightness and signs of corrosion or wear. Cleaning the screw and its surrounding area, and applying a protective coating if necessary, can help prevent issues related to corrosion. Additionally, monitoring the screw’s condition during routine maintenance checks will allow for early detection of any potential problems.

Comparative Analysis

When compared to standard screws, the 4325147 Fracture Resistant Screw offers enhanced performance and durability due to its material composition and design features. While standard screws may be sufficient for less demanding applications, the 4325147 is specifically engineered to withstand the high stress and harsh conditions encountered in commercial truck operations. This makes it a more suitable choice for critical applications where reliability is paramount 3.

Cummins: A Brief Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a rich history and a strong reputation for reliability and innovation, Cummins continues to be a trusted name among professionals in the field. Their dedication to excellence is evident in the design and performance of components like the 4325147 Fracture Resistant Screw.

Fracture Resistant Screw 4325147 in Cummins Engines

The Fracture Resistant Screw 4325147, manufactured by Cummins, is a critical component in several engine systems. This part is designed to enhance the durability and reliability of the engine by preventing fractures that could otherwise lead to catastrophic failures.

Application in ISV Engines

In the ISV (Nissan) engines, the Fracture Resistant Screw 4325147 is utilized in various critical assemblies. Its primary role is to secure components under high stress and vibration conditions, ensuring that the engine maintains its structural integrity over prolonged periods of operation.

Integration with Cummins Engines

When integrated into Cummins engines, the 4325147 screw is often found in areas where high torque and frequent thermal cycling occur. Its design allows it to withstand these harsh conditions without succumbing to fatigue or fracture, thereby contributing to the overall longevity and performance of the engine.

Grouping of Engines

The Fracture Resistant Screw 4325147 is particularly beneficial in groupings of engines that are subject to heavy-duty applications. These include:

- Industrial Engines: Where the screw is used in heavy machinery and construction equipment.

- Marine Engines: For applications in boats and ships, where the screw must endure the corrosive effects of saltwater.

- Power Generation Engines: Used in generators that operate continuously, requiring components that can resist wear and tear.

Each of these applications benefits from the enhanced durability provided by the 4325147 screw, ensuring that the engine can perform reliably in demanding environments.

Role of Part 4325147 Fracture Resistant Screw in Engine Components

In the intricate assembly of engine systems, the part 4325147 Fracture Resistant Screw plays a significant role in ensuring the structural integrity and reliable operation of various components.

Block and Cylinder Block

The block, often referred to as the cylinder block, is the backbone of an engine, housing the cylinders and providing a sturdy foundation for other components. The 4325147 screw is utilized in the assembly of the cylinder block to secure critical components such as the cylinder liners and main bearing caps. Its fracture-resistant properties ensure that these connections remain intact under the high stresses and vibrations encountered during engine operation.

Cylinder

Within the cylinder block, individual cylinders are where the combustion process occurs. The 4325147 screw is employed to fasten cylinder liners or sleeves, which are precision-machined to ensure a tight seal with the piston rings. This secure attachment is vital for maintaining compression and preventing leaks, directly influencing engine performance and efficiency.

Long Block Kit

A long block kit includes the cylinder block, crankshaft, pistons, and other essential components, excluding ancillary systems like the fuel injection and ignition components. The 4325147 screw is integral in assembling this kit, particularly in securing the main bearing caps to the block. This ensures that the crankshaft is properly supported and aligned, which is fundamental for smooth operation and longevity of the engine.

Short Block Kit

Similar to the long block kit, the short block kit comprises the cylinder block, crankshaft, pistons, and connecting rods, but without the cylinder head and valve train. The 4325147 screw is used to fasten various components within the short block, such as the main bearing caps and cylinder liners. Its robust design helps withstand the dynamic forces generated during engine operation, contributing to the overall durability and reliability of the short block assembly.

Conclusion

In summary, the 4325147 Fracture Resistant Screw is a key component in the assembly and operation of engine systems, providing essential support and stability to critical engine parts. Its high-strength material composition, design features, and resistance to mechanical stress make it a reliable choice for demanding applications in commercial trucks and heavy-duty engines.

-

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

An Introduction to Modern Vehicle Design, Julian Happian-Smith, Butterworth-Heinemann, 2002

↩ -

Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Dominique Bonneau, Aurelian Fatu and Dominique Souchet, Wiley-ISTE, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.