This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

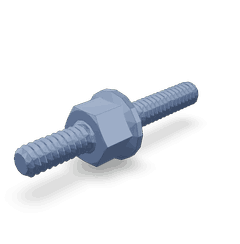

The Studded Flange Cap Screw Part #4325276 is a specialized fastener produced by Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry. This component is designed for use in commercial trucks, where it plays a significant role in securing various mechanical assemblies. Cummins is well-known for its commitment to quality and innovation, ensuring that their components meet the rigorous demands of commercial vehicle applications.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that combines the features of a stud and a flanged bolt. It is commonly used in mechanical assemblies to provide a secure connection between components. The stud portion of the screw allows for repeated assembly and disassembly, while the flange provides additional stability and prevents the screw from pulling through the material. This type of fastener is particularly useful in applications where vibration and dynamic loads are present, as it offers enhanced holding power and resistance to loosening 1.

Purpose and Role in Truck Operation

The Studded Flange Cap Screw Part #4325276 is specifically designed for use in commercial trucks. It is utilized in various applications where secure fastening is required, such as in engine components, transmission systems, and chassis assemblies. By providing a robust connection, this screw contributes to the overall stability and reliability of the truck’s mechanical systems. Its design ensures that critical components remain firmly in place, even under the harsh conditions encountered in commercial truck operations.

Key Features

The Studded Flange Cap Screw Part #4325276 boasts several key features that enhance its functionality:

- Material Composition: Constructed from high-strength steel, this screw offers excellent durability and resistance to wear and corrosion.

- Design Elements: The flanged design provides additional surface area for load distribution, reducing the risk of pull-through and enhancing stability.

- Thread Type: Features a coarse thread for quick and secure fastening, ensuring efficient installation and removal.

- Coating: May include a protective coating to further resist corrosion and extend service life.

Benefits

Using the Studded Flange Cap Screw Part #4325276 offers several advantages:

- Improved Durability: The high-strength steel material and protective coating contribute to a longer service life, even in demanding environments.

- Reliability: The flanged design and coarse thread ensure a secure connection that resists loosening over time.

- Ease of Installation: The screw’s design allows for quick and straightforward installation, reducing downtime during maintenance procedures.

- Comparison with Alternatives: Compared to traditional bolts and nuts, the studded flange cap screw provides a more stable and vibration-resistant connection, making it a preferred choice in commercial truck applications.

Installation Process

Proper installation of the Studded Flange Cap Screw Part #4325276 involves the following steps:

- Preparation: Ensure the mating surfaces are clean and free of debris.

- Alignment: Position the screw through the designated holes in the components to be joined.

- Torque Application: Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings. This ensures the connection is secure without over-tightening, which could damage the components.

- Verification: Check the connection for stability and proper alignment. Ensure there is no excessive play or movement.

Troubleshooting and Maintenance

Common issues with the Studded Flange Cap Screw Part #4325276 may include loosening due to vibration or corrosion. To address these issues:

- Inspection: Regularly inspect the screw for signs of wear, corrosion, or damage.

- Tightening: If loosening is detected, re-torque the screw to the specified settings.

- Replacement: If significant corrosion or damage is present, replace the screw with a new one to maintain the integrity of the connection.

- Lubrication: Apply a thread locker or anti-seize compound to the threads during installation to prevent corrosion and facilitate future removal.

Safety Considerations

When working with the Studded Flange Cap Screw Part #4325276, observe the following safety guidelines:

- Personal Protective Equipment (PPE): Wear appropriate PPE, including gloves and safety glasses, to protect against injury.

- Tool Use: Use the correct tools, such as a torque wrench, to ensure proper installation and avoid over-tightening.

- Work Environment: Ensure the work area is clean and free of hazards to prevent accidents during installation.

Cummins Overview

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, with a rich history of innovation and quality. Founded in 1919, Cummins has built a reputation for producing reliable and high-performance components. Their commitment to research and development ensures that their products meet the evolving needs of the industry, providing customers with durable and efficient solutions for their commercial vehicle applications.

Studded Flange Cap Screw (Part 4325276) in Cummins Engines

The Studded Flange Cap Screw, identified by part number 4325276, is a crucial component in various Cummins engines. This part is designed to secure flanges and other components, ensuring a tight and reliable connection. Its application spans across different engine models, providing a consistent and dependable fastening solution.

ISV (Nissan)

In the ISV (Nissan) engines, the Studded Flange Cap Screw is integral to maintaining the structural integrity of the engine. It is used to fasten various flanges, ensuring that they remain securely in place under operational stresses. This is particularly important in the ISV engines, where reliability and performance are paramount.

The use of this screw in the ISV engines highlights its versatility and effectiveness in demanding environments. Its design allows for easy installation and removal, which is crucial during maintenance and repair operations. The studded feature of the screw provides additional grip and stability, reducing the risk of loosening over time.

The Studded Flange Cap Screw is a testament to Cummins’ commitment to quality and durability. Its application in the ISV engines underscores its importance in achieving optimal engine performance and longevity.

Role of Part 4325276 Studded Flange Cap Screw in Engine Systems

The Part 4325276 Studded Flange Cap Screw is an essential fastening component utilized in various engine systems to ensure secure and reliable connections. Its application spans multiple critical areas within the engine, contributing to the overall integrity and functionality of the system.

In the Crankcase Breather Arrangement, the studded flange cap screw plays a significant role in securing the breather components. This ensures that the crankcase ventilation system operates efficiently, allowing for the release of pressure and contaminants from the crankcase while preventing the escape of oil vapors into the atmosphere. Proper fastening is vital to maintain the system’s effectiveness and prevent oil leaks.

Within the Thermostat Housing Arrangement, the studded flange cap screw is used to fasten the thermostat housing to the engine block or intake manifold. This connection is important for maintaining the integrity of the cooling system, ensuring that the thermostat can regulate the engine’s temperature effectively. A secure fit prevents coolant leaks and ensures consistent engine performance.

In the context of a Long Block Kit, the studded flange cap screw is often employed to attach various components to the engine block. This includes securing gaskets, sensors, and other accessories that are part of the long block assembly. The reliable fastening provided by this screw ensures that all components remain in place during engine operation, contributing to the durability and performance of the engine.

For the Mounting of the Thermostat Housing, the studded flange cap screw is critical in ensuring that the housing is firmly attached to the engine. This secure mounting is essential for the proper function of the thermostat, which controls the flow of coolant through the engine, thereby regulating its temperature. A well-mounted thermostat housing prevents coolant loss and ensures efficient engine cooling.

Overall, the Part 4325276 Studded Flange Cap Screw is a versatile and reliable component that enhances the functionality and durability of various engine systems. Its role in securing critical components ensures that the engine operates smoothly and efficiently.

Conclusion

The Studded Flange Cap Screw Part #4325276 by Cummins is a vital component in the automotive and heavy-duty truck industry. Its robust design, high-strength material, and reliable performance make it an indispensable part in securing various mechanical assemblies in commercial trucks. Whether used in engine components, transmission systems, or chassis assemblies, this screw ensures that critical components remain firmly in place, contributing to the overall stability and reliability of the vehicle. Cummins’ commitment to quality and innovation is evident in the design and functionality of this part, making it a preferred choice for demanding commercial vehicle applications.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.