This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

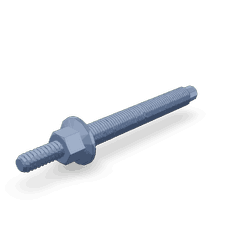

The Studded Flange Cap Screw, part number 4325278, manufactured by Cummins, is a specialized fastener designed for heavy-duty truck applications. Cummins, a renowned name in the automotive industry, produces this component to meet the demanding requirements of truck mechanics and operators. This screw is integral to ensuring the secure attachment of flanges and other critical components within a truck’s mechanical system.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a cap screw. The stud is designed to pass through holes in flanges or other components, while the cap screw threads onto the stud to secure the assembly. This design allows for a robust connection that can withstand significant stress and vibration, common in heavy-duty truck operations 1.

Purpose and Role

This Cummins part plays a significant role in the operation of a truck by securing flanges and other components. It ensures that these parts remain firmly attached under various operating conditions, including high torque and dynamic loads. Its application is vital in maintaining the integrity of the truck’s mechanical systems, contributing to overall performance and safety 2.

Key Features

The Studded Flange Cap Screw features a design that includes a threaded stud and a cap screw, both typically made from high-strength materials such as alloy steel. This material composition enhances its durability and resistance to wear. Additionally, the screw may have unique attributes such as a flanged head, which provides a larger bearing surface and improves the distribution of clamping force 3.

Benefits

Using this part in truck maintenance and operation offers several advantages. Its robust design and material composition contribute to durability and reliability, ensuring long-term performance. The ease of installation is another benefit, as the screw can be quickly and securely fastened, reducing downtime during maintenance procedures.

Installation Process

Proper installation of the Studded Flange Cap Screw involves several steps. First, ensure that the holes in the flanges or components are clean and free of debris. Next, insert the stud through the holes and align it with the cap screw. Thread the cap screw onto the stud, tightening it to the manufacturer’s specified torque settings to ensure a secure fit without over-tightening, which could damage the components.

Troubleshooting and Maintenance

Common issues with the Studded Flange Cap Screw may include loosening over time due to vibration or wear. Regular inspection and tightening can prevent this. If corrosion is observed, cleaning the affected areas and applying a suitable lubricant or anti-seize compound can help maintain performance. Proper maintenance practices, such as periodic checks and re-torquing, are essential for ensuring longevity and optimal performance.

Safety Considerations

When working with the Studded Flange Cap Screw, it is important to observe several safety guidelines. Use the appropriate tools to avoid damage to the screw or surrounding components. Wear personal protective equipment, such as gloves and safety glasses, to protect against injury. Additionally, ensure that the truck is securely supported and the engine is off during installation or maintenance procedures to prevent accidental movement or injury.

Cummins Overview

Cummins is a well-established manufacturer in the automotive industry, known for its commitment to quality and innovation. The company has a reputation for producing reliable and high-performance components, including the Studded Flange Cap Screw. Cummins’ dedication to excellence is evident in their rigorous testing and quality control processes, ensuring that their products meet the highest standards for durability and performance in heavy-duty applications.

Studded Flange Cap Screw in Cummins Engines

Part number 4325278 is a critical component in the assembly of various Cummins engines, including those used in the ISV (Industrial and Small Vehicle) lineup by Nissan. This part is essential for securing flanges and ensuring a tight seal, which is crucial for the proper functioning of the engine.

Application in Cummins Engines

This part is utilized in several Cummins engine models, providing a reliable method for fastening components together. Here are some of the key applications:

-

Cummins QSK Series: This series of engines is known for its robust design and high performance. The studded flange cap screw is used to secure various flanges, ensuring that connections remain tight and secure under high-stress conditions.

-

Cummins L Series: These engines are designed for a variety of applications, from industrial to marine. The studded flange cap screw is integral in maintaining the integrity of flange connections, which is vital for the overall performance and longevity of the engine.

-

Cummins K Series: Known for their versatility and durability, the K series engines often incorporate the studded flange cap screw in their design. This ensures that all flange connections are properly secured, preventing leaks and maintaining operational efficiency.

Importance in Engine Assembly

This part plays a pivotal role in the assembly of Cummins engines. Its design allows for a secure and tight fit, which is essential for preventing leaks and ensuring that all components are properly aligned. This is particularly important in high-pressure environments where any failure in the flange connections can lead to significant issues.

Compatibility with ISV Engines

In the context of ISV engines by Nissan, the studded flange cap screw is a key component in maintaining the reliability and efficiency of the engine. Its use in these engines highlights its importance in ensuring that all flange connections are secure, which is crucial for the overall performance of the engine.

This part is a testament to the precision and quality that Cummins brings to its engine components. Its application across various engine series underscores its versatility and critical role in engine assembly.

Role of Part 4325278 Studded Flange Cap Screw in Engine Systems

In the intricate assembly of engine systems, this part plays a significant role in ensuring the secure fastening of various components. This component is instrumental in maintaining the structural integrity and operational efficiency of the engine.

Camshaft Assembly

Within the camshaft assembly, the 4325278 studded flange cap screw is utilized to fasten the camshaft to the engine block or cylinder head. This secure attachment is essential for the precise operation of the valve train, ensuring that the valves open and close at the correct times in synchronization with the pistons’ movements.

Connecting Rod and Piston

In the connecting rod and piston assembly, the 4325278 studded flange cap screw is employed to secure the connecting rod to the crankshaft. This connection is vital for transmitting the linear motion of the pistons into rotational motion of the crankshaft, a fundamental aspect of the engine’s power generation.

Fuel Injector Mounting

For fuel injectors, the 4325278 studded flange cap screw is used to mount the injectors securely to the cylinder head. This ensures that the injectors are held in the correct position and orientation, allowing for accurate fuel delivery into the combustion chamber, which is critical for engine performance and efficiency.

Long Block Kit Integration

In a long block kit, which includes the engine block, crankshaft, pistons, and other essential components, the 4325278 studded flange cap screw is used extensively to assemble and secure various parts. Its role in this context is to provide a reliable fastening solution that can withstand the high stresses and vibrations inherent in engine operation.

Performance Parts Enhancement

When upgrading to performance parts, the 4325278 studded flange cap screw is often utilized to secure high-performance components such as aftermarket camshafts, connecting rods, and fuel injectors. Its robust design ensures that these performance-oriented parts remain securely in place, even under the increased stresses of enhanced engine operation.

Overall, the 4325278 studded flange cap screw is a versatile and reliable fastening component that plays a key role in the assembly and secure operation of various engine systems.

Conclusion

The 4325278 Studded Flange Cap Screw is a critical component in the assembly and maintenance of heavy-duty truck engines. Its robust design, high-strength material composition, and ease of installation make it an essential part for ensuring the secure attachment of flanges and other critical components. Regular maintenance and proper installation practices are vital for maximizing the performance and longevity of this part in demanding engine environments.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.