4325473

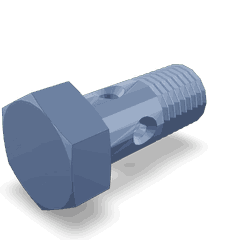

Banjo Connector Screw

Cummins®

IN STOCK

2 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4325473 Banjo Connector Screw, manufactured by Cummins, is a specialized component used in heavy-duty truck systems. This part plays a role in connecting various fluid systems, ensuring the secure transfer of fluids such as hydraulic, fuel, and lubrication. Understanding the function and importance of banjo connector screws is vital for maintaining the efficiency and reliability of these systems.

Basic Concepts of Banjo Connector Screws

A banjo connector screw is a type of fitting used to connect hoses or pipes in fluid systems. It typically consists of a bolt, a banjo fitting (a small, flat, oval-shaped piece), and washers or seals. The banjo fitting is clamped between two surfaces, creating a seal that allows fluid to pass through while preventing leaks. These connectors are widely used in automotive and industrial applications due to their reliability and ease of installation 1.

Purpose and Role in Truck Operation

This Cummins part is integral to the operation of heavy-duty trucks. It is used in hydraulic systems to connect hoses that transfer hydraulic fluid, in fuel systems to link fuel lines, and in lubrication systems to ensure proper oil flow. The screw’s design allows for secure connections that withstand high pressure and vibration, which are common in truck operations 2.

Key Features

The 4325473 features several design elements that enhance its performance and durability. It is made from high-quality materials resistant to corrosion and wear. The screw has a specific thread type that ensures a tight fit, and it incorporates sealing mechanisms such as washers or O-rings to prevent leaks. Its design specifications are tailored to meet the demanding requirements of heavy-duty applications.

Benefits

Using the 4325473 offers several advantages. It provides improved sealing compared to other types of connector screws, ensuring a leak-free connection. The design allows for easy installation, reducing downtime during maintenance. Its resistance to corrosion extends the component’s lifespan, and its robust construction ensures longevity even under harsh operating conditions.

Installation and Usage Guidelines

Proper installation of the 4325473 is crucial for its effective function. Begin by ensuring the mating surfaces are clean and free of debris. Apply the appropriate sealant to the threads if required. Insert the banjo fitting into the connection point and secure it with the screw, using the recommended torque specifications to avoid over-tightening, which could damage the fitting or cause leaks. Regular inspection and maintenance will help ensure a secure and leak-free connection.

Troubleshooting and Maintenance

Common issues with banjo connector screws include leaks, corrosion, and wear. To address leaks, check the seals and washers for damage and replace them if necessary. Corrosion can be mitigated by using screws made from corrosion-resistant materials and applying protective coatings. Regular inspection for signs of wear, such as cracks or deformation, is recommended. Replace the screw if any damage is detected to maintain system reliability.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is known for its commitment to quality and innovation. The company offers a wide range of products for the heavy-duty truck sector, including engines, powertrain components, and aftermarket parts, all designed to meet the rigorous demands of commercial transportation 3.

Cummins Banjo Connector Screw 4325473 in Engine Applications

The Cummins Banjo Connector Screw part number 4325473 is a critical component in various engine systems, ensuring secure and leak-proof connections for hydraulic or fuel lines. This part is designed to fit seamlessly into the engine architecture, providing a reliable method for attaching hoses to the engine’s fuel or hydraulic systems.

ISV (Nissan)

In the ISV (Nissan) engine, the 4325473 is utilized to secure the fuel lines, ensuring that the fuel delivery system remains intact and efficient. This component is essential for maintaining the engine’s performance and reliability, as it prevents fuel leaks that could lead to engine damage or safety hazards.

X12 CM2350 X119B

For the X12 CM2350 X119B engine, the 4325473 is employed in both fuel and hydraulic systems. Its robust design ensures that the connections are tight and secure, which is crucial for the engine’s operational integrity. This part’s precision engineering guarantees that the engine can handle the pressures and stresses of its operational environment without compromising on safety or efficiency.

The use of the Cummins 4325473 in these engines highlights its versatility and importance in maintaining the functionality and safety of the engine systems. Its application across different engine models underscores its reliability and effectiveness in ensuring that the engine operates smoothly and efficiently.

Role of Part 4325473 Banjo Connector Screw in Engine Systems

The Part 4325473 is an essential component in various engine systems, facilitating secure and efficient fluid transfer. Its applications span across multiple critical systems, ensuring optimal performance and reliability.

Fuel System Integration

In the fuel system, the Banjo Connector Screw is utilized to connect the fuel drain tube to the long block kit. This connection is vital for the proper drainage of fuel, ensuring that any excess or contaminated fuel is efficiently removed from the system. The secure fitting provided by the Banjo Connector Screw prevents leaks, maintaining the integrity of the fuel system and ensuring consistent fuel delivery to the engine.

Turbocharger Oil Supply

The Banjo Connector Screw plays a significant role in the turbocharger oil supply system. It is employed to connect the turbocharger oil supply tube to the turbocharger. This connection ensures that the turbocharger receives a steady supply of oil, which is essential for lubrication and cooling. The Banjo Connector Screw’s robust design withstands the high pressures and temperatures within the oil supply system, contributing to the turbocharger’s longevity and performance.

General Plumbing Applications

Beyond specific systems, the Banjo Connector Screw is widely used in general plumbing applications within the engine. It provides a reliable connection for various fluid lines, including coolant and hydraulic systems. The screw’s design allows for easy installation and removal, making it a preferred choice for maintenance and repair tasks. Its ability to create a leak-proof seal is particularly beneficial in systems where fluid integrity is paramount.

Turbocharger Oil Return

In addition to the oil supply, the Banjo Connector Screw is also integral to the turbocharger oil return system. It connects the turbocharger oil return line, ensuring that used oil is efficiently returned to the sump or reservoir. This connection is crucial for maintaining the oil level and pressure within the turbocharger, contributing to its overall efficiency and reliability.

The Banjo Connector Screw’s versatility and reliability make it a cornerstone component in various engine systems, enhancing performance and ensuring the smooth operation of fluid transfer mechanisms.

Conclusion

The 4325473 Banjo Connector Screw is a vital component in heavy-duty truck systems, ensuring secure and efficient fluid transfer across various engine systems. Its robust design, resistance to corrosion, and ease of installation make it an indispensable part for maintaining the reliability and performance of heavy-duty trucks. Proper installation, regular maintenance, and timely replacement of this part are essential for ensuring the longevity and efficiency of the fluid systems in which it is used.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Meherwan P. Boyce, Gas Turbine Engineering Handbook, Second Edition (Gulf Professional Publishing, 2002).

↩ -

Gijs Mom, The Evolution of Automotive Engineering: A Handbook (SAE International, 2023).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.