This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Studded Flange Cap Screw, identified by part number 4325873, is a component manufactured by Cummins, a well-established name in the automotive industry. This screw is significant in commercial trucks due to its role in ensuring secure fastenings across various truck components. Cummins is renowned for its commitment to quality and innovation in manufacturing truck components, making this part a reliable choice for maintaining the integrity and performance of truck systems 1.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener characterized by a threaded shank and a flanged head. Its primary function is to provide a secure connection between two or more components within mechanical systems. The studded flange design allows for additional surface contact, enhancing the screw’s ability to resist loosening under vibration and stress. This type of screw operates by threading into a pre-drilled hole, creating a tight and stable connection that is crucial for the operation of various truck components 2.

Purpose of the Studded Flange Cap Screw

In the context of a commercial truck, the Studded Flange Cap Screw plays a role in securing components that are subject to significant stress and vibration. It is commonly used in applications such as engine mounts, exhaust systems, and chassis components. By providing a secure and stable connection, this screw contributes to the overall reliability and safety of the truck. Its applications extend to various truck components and systems, ensuring that critical parts remain firmly in place under operating conditions 3.

Key Features

The Studded Flange Cap Screw is designed with specific elements that enhance its performance and durability. The studded flange provides additional contact area, which helps in distributing the load more evenly and reducing the risk of loosening. The threading is precision-cut to ensure a tight fit, and the material used is typically a high-strength alloy to withstand the rigors of truck operation. Additionally, special coatings or treatments may be applied to the screw to improve corrosion resistance and further enhance its longevity 4.

Benefits

Using the Studded Flange Cap Screw offers several advantages. Its design contributes to enhanced durability, making it suitable for applications where components are exposed to high levels of stress and vibration. The resistance to loosening ensures that connections remain secure over time, reducing the need for frequent maintenance. Furthermore, the ease of installation and removal simplifies repair and maintenance procedures, allowing for efficient servicing of truck components.

Installation Process

Installing the Studded Flange Cap Screw requires following specific procedures to ensure a secure and proper connection. Begin by ensuring the mating surfaces are clean and free of debris. Insert the screw into the pre-drilled hole and use a torque wrench to tighten it to the manufacturer’s specified torque settings. It is important to avoid over-tightening, which can damage the screw or the components being fastened. Additionally, periodic checks should be performed to ensure the screw remains tight, especially in applications subject to high vibration.

Troubleshooting Common Issues

Typical problems that may arise with the Studded Flange Cap Screw include loosening, corrosion, or damage. If loosening is detected, re-tighten the screw to the specified torque settings. In cases of corrosion, cleaning the affected area and applying a corrosion-resistant coating can help. Damage to the screw may require replacement with a new part to ensure the integrity of the connection. Regular inspections can help identify issues early, allowing for timely intervention.

Maintenance Tips

To ensure the longevity and reliability of the Studded Flange Cap Screw, regular maintenance practices are recommended. Inspect the screw and its connections at regular intervals, checking for signs of loosening, corrosion, or damage. Cleaning the screw and its mating surfaces can prevent the buildup of debris and corrosion. Applying a protective coating can further enhance resistance to environmental factors. Following these maintenance tips will help maintain the performance and durability of the screw.

Cummins: Manufacturer Overview

Cummins has a long-standing reputation in the automotive industry for producing high-quality truck components. Founded with a commitment to innovation and excellence, Cummins has consistently delivered reliable and durable parts that meet the demanding requirements of commercial trucks. Their focus on quality and customer satisfaction has established them as a trusted manufacturer in the industry, ensuring that components like the Studded Flange Cap Screw are designed and produced to the highest standards.

Application in Cummins Engines

Cummins B Series Engines: The Studded Flange Cap Screw is utilized in the Cummins B Series engines, which are known for their reliability and performance in various applications. This screw ensures that flanges are tightly secured, preventing leaks and maintaining the structural integrity of the engine.

Cummins C Series Engines: In the Cummins C Series engines, the Studded Flange Cap Screw plays a vital role in maintaining the connection between different engine components. Its robust design ensures that the flanges remain firmly attached, which is crucial for the engine’s overall performance and longevity.

Cummins K Series Engines: The K Series engines also benefit from the use of the Studded Flange Cap Screw. This part is integral in securing various flanges, ensuring that the engine operates smoothly and efficiently. The screw’s studded design provides additional grip and stability, which is essential in high-stress environments.

Cummins L Series Engines: For the L Series engines, the Studded Flange Cap Screw is a key component in maintaining the integrity of flange connections. Its use ensures that the engine’s components are securely fastened, contributing to the engine’s durability and performance.

Cummins M Series Engines: In the Cummins M Series engines, the Studded Flange Cap Screw is employed to secure flanges in critical areas. This ensures that the engine’s components remain tightly connected, which is essential for preventing leaks and maintaining optimal engine function.

Cummins N Series Engines: The N Series engines also utilize the Studded Flange Cap Screw to secure flanges. This part is crucial in maintaining the structural integrity of the engine, ensuring that all components are properly fastened and aligned.

Cummins Q Series Engines: For the Q Series engines, the Studded Flange Cap Screw is a vital component in securing flanges. Its use ensures that the engine’s connections are robust and reliable, contributing to the engine’s overall performance and longevity.

Cummins X Series Engines: In the Cummins X Series engines, the Studded Flange Cap Screw is essential for securing flanges. This part ensures that the engine’s components are tightly fastened, which is crucial for preventing leaks and maintaining the engine’s structural integrity.

Cummins ISV Engines: The Studded Flange Cap Screw is also used in Cummins ISV engines, which are known for their versatility and performance in various applications. This screw ensures that flanges are securely fastened, contributing to the engine’s reliability and efficiency.

By ensuring that flanges are tightly secured, the Studded Flange Cap Screw is a critical component in maintaining the performance and longevity of Cummins engines across various series.

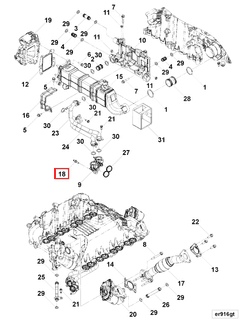

Role of Part 4325873 Studded Flange Cap Screw in Engine Systems

Recirculation Systems

In recirculation systems, the 4325873 Studded Flange Cap Screw is instrumental in maintaining the integrity of connections within the system. This part is often used to secure components such as filters, valves, and manifolds, ensuring that the recirculated fluids or gases are contained within the system without leakage. Its robust design allows it to withstand the pressure and temperature variations typical in recirculation applications, providing a reliable seal that is essential for the efficient operation of the system.

Exhaust Systems

Within exhaust systems, the 4325873 Studded Flange Cap Screw plays a significant role in connecting various components such as catalytic converters, mufflers, and tailpipes. It is designed to endure the high temperatures and corrosive environments present in exhaust systems. By securely fastening these components, it ensures that the exhaust gases are directed away from the engine compartment efficiently. This not only contributes to the overall performance of the vehicle but also aids in reducing emissions by maintaining the structural integrity of the exhaust path.

Conclusion

The Studded Flange Cap Screw (Part #4325873) by Cummins is a critical component in various truck and engine systems, ensuring secure and reliable connections across a range of applications. Its robust design, high-strength materials, and resistance to loosening make it an essential part for maintaining the integrity and performance of commercial trucks and engines. Regular maintenance and proper installation procedures are key to maximizing the longevity and effectiveness of this part.

References

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Reif, K. (Ed.). (2014). Diesel Engine Management Systems and Components. Springer Vieweg.

↩ -

Mananathan, R. (2022). Automobile Wheel Alignment and Wheel Balancing. SAE International.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.