This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 4349923, is a specialized fastener produced by Cummins, a renowned manufacturer in the commercial truck industry. This screw is integral to the assembly and maintenance of various truck components, ensuring both the structural integrity and operational efficiency of commercial vehicles.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of bolt characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient tightening and loosening using a wrench or socket, while the flange provides additional surface area for distribution of clamping force, reducing the risk of the screw pulling through the material. In mechanical systems, these screws are used to secure components that require a high degree of stability and resistance to vibration 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation of commercial trucks by securing critical components. It is designed to withstand the rigors of heavy-duty applications, ensuring that parts remain firmly attached under various operating conditions. This screw is particularly useful in applications where vibration and dynamic loads are common, as its design helps maintain a secure connection over time 2.

Key Features

The 4349923 features a hexagonal head that facilitates easy and precise tightening. The flange beneath the head enhances the screw’s ability to distribute clamping force evenly, which is crucial for maintaining a secure connection. Additionally, the screw is made from high-quality materials that offer excellent resistance to corrosion and wear, ensuring durability in demanding environments 3.

Benefits

The benefits of using this part include enhanced fastening security, resistance to loosening due to vibration, and durability in heavy-duty applications. Its design allows for efficient installation and removal, reducing maintenance time and costs. The screw’s resistance to corrosion ensures long-term reliability, even in harsh operating conditions 4.

Installation Considerations

Proper installation of the 4349923 is crucial for optimal performance and longevity. It is important to follow torque specifications provided by the manufacturer to ensure the screw is tightened to the correct level, avoiding over-tightening or under-tightening. Using the appropriate tools and techniques during installation will help achieve a secure and lasting connection 5.

Troubleshooting and Maintenance

Common issues with the 4349923 may include loosening due to vibration or corrosion. Regular inspections can help identify these issues early. Maintenance procedures may involve re-tightening the screw to the specified torque or replacing it if corrosion or damage is detected. Keeping the screw and surrounding areas clean and free of debris can also help prevent issues 6.

Safety Considerations

When working with the 4349923, it is important to follow safety precautions to ensure personal safety and the integrity of the truck’s components. This includes using the correct tools for installation and removal, wearing appropriate personal protective equipment, and following proper handling, storage, and disposal practices to prevent accidents and ensure the screw’s effectiveness 7.

Cummins Overview

Cummins is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance truck components, Cummins has established a strong reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers ensures that its products, like the 4349923, are designed to deliver superior performance and durability 8.

Application in Cummins Engines

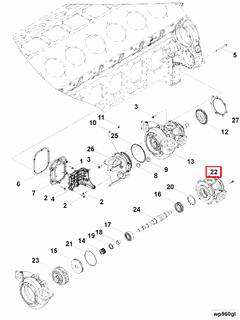

QSK95 CM2350 K111 and QSK95 CM2350 K113

The Hexagon Flange Head Cap Screw, part number 4349923, is integral to the assembly and maintenance of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines. These engines are known for their robust performance and are utilized in a variety of heavy-duty applications, including marine, power generation, and industrial sectors. The screw’s design allows it to securely fasten components, ensuring that parts remain tightly secured during operation, which is crucial for maintaining engine integrity and performance.

The flange head design of the screw provides a large bearing surface, which is essential for distributing the load evenly and preventing damage to the fastened parts. This feature is particularly important in the high-vibration and high-stress environments typical of these engines. The hexagon shape of the head allows for efficient use of standard wrenches and sockets, facilitating quick and easy assembly and maintenance.

Importance in Engine Assembly

In the assembly of the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines, the Hexagon Flange Head Cap Screw is used in numerous applications, including securing engine covers, mounting brackets, and other critical components. Its use ensures that all parts are held firmly in place, which is vital for the engine’s overall performance and longevity.

The material and finish of part 4349923 are chosen to withstand the harsh conditions within the engine, including high temperatures, exposure to lubricants, and mechanical stress. This ensures that the screw maintains its structural integrity and fastening capability over the engine’s operational life.

Maintenance and Replacement

During routine maintenance and repairs, the Hexagon Flange Head Cap Screw is a common part that may need to be replaced. Its standardized design makes it easy to source and install, minimizing downtime and ensuring that the engine can return to operation quickly. Technicians and engineers rely on this part for its consistent performance and ease of use, making it a staple in the maintenance toolkit for these engines.

The use of part 4349923 in the QSK95 CM2350 K111 and QSK95 CM2350 K113 engines underscores Cummins’ commitment to quality and reliability in their engine components. This part’s design and functionality are critical to the overall performance and durability of these engines, making it an essential element in the engine’s assembly and maintenance.

Role of Part 4349923 Hexagon Flange Head Cap Screw in Engine Systems

In the context of engine systems, the part 4349923 is instrumental in ensuring the secure assembly and reliable operation of various components.

Water Pump Integration

When it comes to the water pump, the 4349923 screw is often utilized to fasten the pump housing to the engine block or the water pump kit framework. This secure attachment is essential for maintaining the structural integrity of the water pump, which is responsible for circulating coolant throughout the engine to prevent overheating.

Water Pump Kit Assembly

In a water pump kit, which typically includes the water pump, gaskets, and sometimes a thermostat, the 4349923 screw plays a significant role in assembling these components. It ensures that all parts are held firmly in place, allowing for efficient coolant flow and optimal engine temperature regulation.

General Pump Applications

Beyond specific applications like the water pump, the 4349923 screw is versatile enough to be used in various pump assemblies within the engine system. Whether it’s securing pump covers, attaching pump brackets, or fastening pump components, this screw ensures that all parts remain aligned and function as intended.

The use of the 4349923 Hexagon Flange Head Cap Screw in these applications underscores its importance in maintaining the efficiency and reliability of engine systems.

Conclusion

The 4349923 Hexagon Flange Head Cap Screw is a critical component in the assembly and maintenance of Cummins engines, particularly the QSK95 CM2350 K111 and QSK95 CM2350 K113 models. Its design, featuring a hexagonal head and a flange, ensures secure fastening and resistance to vibration, making it indispensable in heavy-duty applications. The screw’s high-quality materials and corrosion resistance contribute to its durability and reliability in demanding engine environments. Proper installation, regular maintenance, and adherence to safety practices are essential to maximize the performance and longevity of this part. Cummins’ commitment to quality is evident in the design and functionality of the 4349923, which plays a vital role in the overall performance and durability of their engines.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5504620.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5504620.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5504620.

↩ -

Cummins. (n.d.). Operation and Maintenance Manual. Bulletin Number 5504620.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.