This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagonal Flange Head Cap Screw (Part #4359786) manufactured by Cummins is a specialized fastener designed for use in heavy-duty truck components. This screw is significant due to its robust construction and precise engineering, which contribute to the overall reliability and performance of heavy-duty trucks.

Basic Concepts

A Hexagonal Flange Head Cap Screw is a type of fastener characterized by its hexagonal head, flange feature, and cap screw construction. The hexagonal head allows for efficient torque application using a wrench or socket, ensuring secure fastening. The flange provides additional surface area, which helps distribute the load and prevent the screw from pulling through the material. This design differentiates it from other screws and fasteners, offering enhanced stability and resistance to loosening 1.

Purpose and Role in Truck Operation

This Cummins part plays a role in securing various components within heavy-duty trucks, contributing to their structural integrity. It is commonly used in applications where high torque and resistance to vibration are required, such as in the attachment of engine components, chassis parts, and other critical assemblies. By providing a secure and stable connection, this screw helps maintain the truck’s performance and safety under demanding conditions 2.

Key Features

The key features of the Hexagonal Flange Head Cap Screw include its hexagonal head design, which allows for precise torque application, and its flange feature, which enhances load distribution and prevents pull-through. The cap screw construction ensures a strong and durable connection. These features collectively contribute to the screw’s effectiveness and reliability in heavy-duty applications 3.

Benefits

Using a Hexagonal Flange Head Cap Screw in truck maintenance and assembly offers several benefits. The design allows for improved torque application, ensuring that components are securely fastened. The flange feature provides resistance to loosening, which is crucial in applications subject to vibration and dynamic loads. Additionally, the durable construction of the screw ensures longevity and reliability under heavy-duty conditions 4.

Installation and Usage

Proper installation of the Hexagonal Flange Head Cap Screw is vital for ensuring a secure fit. It is recommended to follow torque specifications provided by the manufacturer to achieve the correct tension without overtightening. Using the appropriate wrench or socket for the hexagonal head will help apply torque evenly and efficiently. Best practices include cleaning the mating surfaces and inspecting the screw for any damage before installation.

Troubleshooting and Maintenance

Common issues associated with Hexagonal Flange Head Cap Screws include loosening due to vibration and corrosion. Regular inspection and maintenance can help identify these issues early. To prolong the lifespan of the screw, it is important to ensure proper installation, use corrosion-resistant coatings where applicable, and replace screws that show signs of wear or damage. Following these maintenance tips will help maintain the integrity and performance of the fastening system.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a history of innovation and quality in engine and component manufacturing. The company is committed to delivering reliable and high-performance products, ensuring that their components, including the Hexagonal Flange Head Cap Screw, meet the rigorous demands of heavy-duty applications.

Cummins Part 4359786 in Nissan Engines

The Cummins part 4359786, a Hexagonal Flange Head Cap Screw, is integral to the assembly and maintenance of various Nissan engines. This part is designed to provide a secure fastening solution, ensuring that components remain tightly connected under operational stresses.

In the context of the ISV (Intelligent Systems Vehicle) engines by Nissan, the Hexagonal Flange Head Cap Screw is utilized in several key areas. It is commonly employed in securing engine covers, brackets, and other structural components that require robust and reliable fastening. This screw’s design allows for easy installation and removal, which is crucial for maintenance and repair processes.

The use of this part in Nissan engines ensures that the engine’s integrity is maintained, preventing any potential loosening or failure of connected parts. Its application is widespread across different engine models, highlighting its versatility and importance in the engine’s overall assembly.

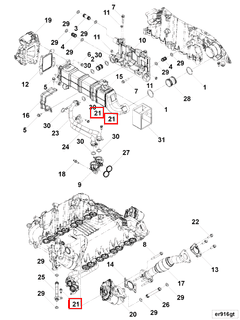

Hexagonal Flange Head Cap Screw in Engine Systems

The part 4359786 Hexagonal Flange Head Cap Screw is integral in securing various components within engine systems, ensuring stability and efficiency.

Air Intake Manifold

In the air intake manifold, this screw plays a significant role in fastening the manifold to the engine block. It ensures a tight seal, preventing air leaks that could affect engine performance. The flange head design provides additional surface area for a more secure fit, reducing the risk of vibration-induced loosening.

Plumbing

For plumbing applications, particularly in oil cooler water systems, the screw is used to secure fittings and connections. Its hexagonal flange head allows for easy tightening with a wrench, ensuring that connections remain sealed under pressure. This is vital for maintaining the integrity of the oil cooling system, which is essential for engine longevity.

Oil Cooler Water Recirculation

In oil cooler water recirculation systems, the screw is employed to fasten components such as hose clamps and bracket mounts. The robust design of the flange head cap screw ensures that these components withstand the dynamic forces and thermal expansions experienced during operation.

Exhaust System

Within the exhaust system, the screw is utilized to secure exhaust manifold bolts and flange connections. Its design helps in distributing the clamping force evenly, which is crucial for maintaining the integrity of the exhaust seals and preventing leaks that could lead to performance issues or increased emissions.

Turbocharger Arrangement

In turbocharger arrangements, the screw is often used to secure turbocharger housings and mounting brackets. The flange head provides additional torque application points, ensuring that the turbocharger remains firmly attached to the engine, even under high-stress conditions.

Turbocharger Kit

For comprehensive turbocharger kits, the screw is a common component for assembling various parts, including intercooler piping and wastegate actuators. Its reliable fastening capability ensures that all elements of the turbocharger system are securely held in place, contributing to optimal turbocharger performance and durability.

Conclusion

The Hexagonal Flange Head Cap Screw (Part #4359786) by Cummins is a critical component in the assembly and maintenance of heavy-duty truck and engine systems. Its robust design, precise engineering, and reliable performance make it an essential fastener for securing various components under demanding conditions. Proper installation, regular maintenance, and the use of this screw in critical applications ensure the longevity and efficiency of heavy-duty engines and trucks.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Bennett, Sean; Norman, Ian Andrew. Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning, 2011.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.