This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4359880 Captive Washer Cap Screw, manufactured by Cummins, is a specialized fastener designed for use in commercial truck operations. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this component to meet the demanding requirements of truck maintenance and repair. This Cummins part is significant in ensuring the reliability and efficiency of various truck systems, contributing to the overall performance and longevity of commercial vehicles.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that includes an integrated washer, which is held in place by a protrusion or step on the screw’s shank. This design ensures that the washer remains attached to the screw during installation, reducing the risk of loss and simplifying the fastening process. The components of a captive washer cap screw typically include the screw head, the shank, the integrated washer, and the threading that allows it to secure into place. Within mechanical systems, these screws play a role in joining components securely while providing a seal that helps prevent leaks and corrosion 1.

Purpose of the 4359880 Captive Washer Cap Screw

The 4359880 Captive Washer Cap Screw is designed to play a role in the operation of commercial trucks by securing various components and systems. Its applications range from fastening engine parts to securing chassis components. The screw’s design ensures a tight and reliable connection, which is vital for the safe and efficient operation of commercial trucks. Its importance lies in its ability to provide a secure fastening solution that can withstand the rigors of heavy-duty truck use 2.

Key Features

The 4359880 Captive Washer Cap Screw boasts several key features that enhance its performance and durability. Its design includes a robust head that provides a secure grip for installation tools, a shank that is resistant to bending and breaking, and an integrated washer that ensures a uniform load distribution and a tight seal. The material composition of the screw, typically a high-strength alloy, contributes to its resistance to corrosion and wear, making it suitable for the harsh environments encountered in commercial truck operations 3.

Benefits

Using the 4359880 Captive Washer Cap Screw offers several advantages. The integrated washer simplifies the installation process, reducing the time and effort required to secure components. The screw’s design contributes to improved reliability, as the captive washer ensures a consistent and secure connection. Additionally, the high-strength material and corrosion resistance of the screw enhance its durability, leading to reduced maintenance needs and longer service life.

Installation Process

Proper installation of the 4359880 Captive Washer Cap Screw involves several steps to ensure a secure and lasting connection. Begin by selecting the appropriate tool for the screw head to avoid damage. Align the screw with the designated hole, ensuring that the integrated washer is correctly positioned. Gradually tighten the screw using consistent torque to avoid over-tightening, which can lead to damage. It is important to follow the manufacturer’s torque specifications to achieve the optimal balance between security and component integrity.

Troubleshooting and Maintenance

Common issues with the 4359880 Captive Washer Cap Screw may include loosening over time or corrosion in harsh environments. To address these issues, regular inspections should be conducted to check for signs of wear or corrosion. If loosening is detected, the screw should be re-tightened to the manufacturer’s specified torque. In cases of corrosion, the affected screw may need to be replaced to maintain system integrity. Regular maintenance, including cleaning and lubrication where appropriate, can help ensure the longevity and optimal performance of the screw.

Compatibility and Applications

The 4359880 Captive Washer Cap Screw is commonly used in various applications within commercial trucks. It is compatible with a range of systems and components, including engine assemblies, chassis structures, and other critical areas where secure fastening is required. Its versatility and reliability make it a preferred choice for maintenance and repair professionals in the commercial truck industry.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer with a rich history in the automotive and heavy-duty truck industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ reputation is built on a foundation of producing reliable and high-performance components that meet the demanding requirements of commercial vehicle operations. The company’s dedication to research and development ensures that its products, including the 4359880 Captive Washer Cap Screw, continue to evolve to meet the needs of the industry.

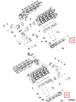

Cummins Part 4359880: Captive Washer Cap Screw in ISV Engines

The Cummins part 4359880, a Captive Washer Cap Screw, is a critical component in the ISV (Infiniti Service Vehicle) engines manufactured by Nissan. This part is integral to the assembly and functionality of the engine, ensuring secure fastening and stability of various engine parts.

In the ISV engines, the Captive Washer Cap Screw is used in several key areas. It is typically employed in securing engine covers, brackets, and other structural components. The cap screw’s design, featuring a captive washer, provides an added layer of reliability by preventing the washer from being lost during assembly or maintenance.

The use of this part in ISV engines highlights its importance in maintaining the integrity and performance of the engine. The cap screw’s robust construction and precise fitment are essential for withstanding the operational stresses and ensuring longevity of the engine components.

By integrating the Captive Washer Cap Screw into the ISV engines, Cummins ensures that the engines benefit from enhanced durability and ease of maintenance. This part’s role in securing various engine parts underscores its significance in the overall engine assembly and operational efficiency.

Role of Part 4359880 Captive Washer Cap Screw in Engine Systems

The Part 4359880 Captive Washer Cap Screw is instrumental in ensuring the secure assembly and reliable operation of various engine components.

Air Intake Manifold

In the air intake manifold, the Part 4359880 Captive Washer Cap Screw is used to fasten the manifold to the engine block or cylinder head. This secure attachment ensures that the manifold remains firmly in place, preventing any air leaks that could affect engine performance. The captive washer within the screw design enhances the sealing capability, maintaining the integrity of the air-fuel mixture entering the combustion chamber.

Long Block Kit

Within a long block kit, which typically includes the engine block, crankshaft, pistons, and other essential components, the Part 4359880 Captive Washer Cap Screw plays a significant role in assembling and securing various parts. It is commonly used to attach ancillary components such as sensors, brackets, and mounting plates. The captive washer ensures that these components remain tightly fastened, contributing to the overall stability and durability of the engine assembly.

Turbocharger Arrangement

In turbocharger arrangements, the Part 4359880 Captive Washer Cap Screw is employed to secure the turbocharger to the engine and exhaust system. This fastening is vital for maintaining the precise alignment and secure attachment of the turbocharger, which is essential for optimal performance and efficiency. The captive washer enhances the screw’s ability to withstand the high temperatures and pressures associated with turbocharged engines, ensuring a reliable and lasting connection.

Conclusion

The 4359880 Captive Washer Cap Screw is a critical component in the maintenance and operation of commercial trucks and engines. Its design, featuring an integrated washer, ensures secure and reliable fastening, contributing to the overall performance and longevity of the vehicle. The screw’s robust construction, resistance to corrosion, and ease of installation make it a preferred choice for professionals in the automotive industry. Regular maintenance and proper installation are essential to maximize the benefits of this part, ensuring the continued reliability and efficiency of commercial truck operations.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.