This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

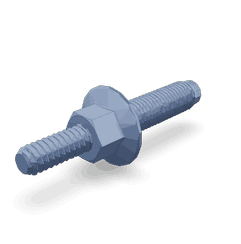

The 4360066 Studded Flange Cap Screw is a specialized fastener produced by Cummins, a well-established manufacturer known for its high-quality automotive components. This screw is designed for use in commercial trucks, where it plays a significant role in ensuring the structural integrity and reliable operation of various truck components.

Basic Concepts

A Studded Flange Cap Screw is a type of fastener that includes a threaded stud and a flanged head. The stud is designed to be inserted through pre-drilled holes in components, while the flanged head provides a broad surface area for distribution of clamping force. This design allows for secure fastening and resistance to loosening under vibration, which is common in heavy-duty truck applications. The screw functions by creating a strong, durable connection between parts, ensuring they remain securely fastened during operation 1.

Purpose and Role in Truck Operation

This Cummins part is integral to the operation of commercial trucks. It is used to secure and maintain the structural integrity of various components, such as engine mounts, transmission housings, and chassis parts. By providing a robust fastening solution, this screw helps to ensure that critical components remain firmly in place, even under the demanding conditions encountered in heavy-duty truck applications 2.

Key Features

The 4360066 Studded Flange Cap Screw boasts several key features that enhance its performance and durability. Its design includes a studded section that threads into a corresponding nut or tapped hole, providing a strong and secure connection. The flanged head distributes clamping force over a larger area, reducing the risk of damage to connected parts. Additionally, the screw is typically made from high-strength materials, such as alloy steel, which offers excellent resistance to corrosion and wear. These features contribute to the screw’s reliability and longevity in demanding truck applications 3.

Benefits

Using the 4360066 Studded Flange Cap Screw offers several benefits. Its robust design and high-strength material composition contribute to improved reliability and safety in truck operations. The screw’s resistance to loosening under vibration helps to maintain secure connections, reducing the risk of component failure. Additionally, the durability of the screw can lead to potential cost savings over time, as it may require less frequent replacement compared to other fasteners.

Installation Process

Proper installation of the 4360066 Studded Flange Cap Screw is crucial for ensuring its effectiveness. The installation process involves several steps:

- Ensure the mating surfaces are clean and free of debris.

- Insert the stud through the pre-drilled holes in the components to be fastened.

- Thread the screw into the corresponding nut or tapped hole.

- Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings.

- Verify that the flanged head is seated properly and that the components are securely fastened.

Troubleshooting Common Issues

Common issues with the 4360066 Studded Flange Cap Screw may include loosening over time, corrosion, or damage to the screw or connected parts. To address these issues:

- Regularly inspect the screw and connected components for signs of wear or corrosion.

- Re-tighten the screw if it becomes loose, ensuring it is torqued to the manufacturer’s specifications.

- Replace the screw if it shows signs of significant corrosion or damage to prevent component failure.

Maintenance Tips

To ensure the longevity and optimal performance of the 4360066 Studded Flange Cap Screw, follow these maintenance tips:

- Perform regular inspections to check for signs of wear, corrosion, or loosening.

- Clean the screw and connected components as needed to remove dirt and debris.

- Re-torque the screw periodically to maintain a secure connection.

- Replace the screw if it shows significant signs of wear or damage.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive industry. Founded in 1919, the company has a history of innovation and commitment to producing high-quality components. Cummins is known for its engines, powertrains, and related technologies, which are used in a wide range of applications, including commercial trucks, construction equipment, and power generation. The company’s dedication to quality and reliability is evident in its products, such as the 4360066 Studded Flange Cap Screw.

Studded Flange Cap Screw 4360066 in Cummins Engines

The Studded Flange Cap Screw 4360066 is a critical component in several Cummins engines, ensuring secure fastening and stability of various parts. This part is designed to withstand high stress and pressure, making it essential for maintaining the integrity of engine components.

ISV (Nissan) Engines

In the ISV (Nissan) engines, the Studded Flange Cap Screw 4360066 plays a vital role in securing flanges and other critical components. Its studded design provides additional grip and resistance to loosening, which is crucial for the high-performance demands of these engines. The screw’s robust construction ensures that it can handle the rigors of continuous operation, maintaining the alignment and stability of connected parts.

The use of this screw in ISV engines highlights Cummins’ commitment to quality and durability, ensuring that the engine operates efficiently and reliably under various conditions. The precision engineering of the Studded Flange Cap Screw 4360066 contributes to the overall performance and longevity of the engine, making it a key component in the assembly of these powerful machines.

Role of Part 4360066 Studded Flange Cap Screw in Engine Systems

The part 4360066 studded flange cap screw is integral to the assembly and securement of various engine components, ensuring their stability and proper function.

Crankcase Breather Arrangement

In the crankcase breather arrangement, the 4360066 screw is used to fasten the breather housing to the engine block. This securement is essential for maintaining the integrity of the breather system, which is responsible for venting crankcase vapors and preventing pressure build-up that could lead to oil leaks or engine damage.

Engine Oil Cooler

For the engine oil cooler, the 4360066 screw plays a role in attaching the cooler to the engine block or mounting bracket. Proper attachment ensures that the oil cooler remains in place, allowing for efficient heat exchange and maintaining optimal oil temperature, which is vital for engine longevity and performance.

Front Sprocket Cover

In the front sprocket cover assembly, the 4360066 screw is employed to secure the cover to the engine casing. This ensures that the sprocket and chain are adequately protected from debris and contaminants, contributing to the smooth operation and durability of the engine’s drive system.

Fuel Filter Mounting

When it comes to fuel filter mounting, the 4360066 screw is utilized to attach the fuel filter housing to the engine or frame. This securement is important for maintaining the filter’s position and ensuring a stable fuel supply to the engine, which is essential for consistent performance and fuel efficiency.

Long Block Kit

In a long block kit, which includes the engine block, crankshaft, pistons, and other essential components, the 4360066 screw is often used in various applications to ensure all parts are correctly assembled and fastened. This includes securing ancillary components such as sensors, brackets, or additional covers, contributing to the overall structural integrity and functionality of the engine.

Conclusion

The 4360066 Studded Flange Cap Screw is a critical component in the operation and maintenance of commercial trucks and Cummins engines. Its robust design, high-strength material, and secure fastening capabilities ensure the structural integrity and reliable operation of various engine components. Proper installation, regular maintenance, and timely replacement are essential for maximizing the performance and longevity of this part.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Reif, K. (Ed.). (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.