This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Hexagonal Flange Head Cap Screw, part number 4360070, is a component manufactured by Cummins, a well-established name in the automotive industry. This screw is significant in heavy-duty truck applications due to its robust design and reliable performance. Cummins is renowned for producing high-quality components that enhance the durability and efficiency of heavy-duty trucks.

Basic Concepts

Hexagonal Flange Head Cap Screws are designed with a hexagonal head and a flange that provides a larger bearing surface. This design allows for easier tightening and loosening using a wrench or socket, reducing the risk of cam-out. These screws are typically made from high-strength materials such as alloy steel, which offers excellent tensile strength and resistance to wear and corrosion. In the automotive industry, they are commonly used to secure critical components that require high load-bearing capacity and resistance to vibration 1.

Functionality and Operation

In the context of heavy-duty trucks, the Hexagonal Flange Head Cap Screw operates by securely fastening components that are subject to high stress and loads. Its design ensures that it can withstand significant forces without loosening, which is vital for maintaining the structural integrity of the truck. The flange head provides additional surface area for load distribution, enhancing the screw’s ability to hold components firmly in place.

Purpose of Part #4360070

The Cummins Hexagonal Flange Head Cap Screw part #4360070 plays a specific role in truck assemblies by ensuring that critical components remain securely fastened. This screw is often used in applications where high tensile strength and resistance to vibration are required, such as in engine mounts, transmission housings, and chassis components. Its use contributes to the overall structural integrity and performance of the truck.

Key Features

The key features of the Hexagonal Flange Head Cap Screw include its hexagonal flange head design, which allows for efficient tightening and loosening. The material properties of the screw, typically high-strength alloy steel, provide excellent tensile strength and durability. Additionally, the flange head offers a larger bearing surface, which enhances load distribution and reduces the risk of component failure under stress.

Benefits

Using the Cummins Hexagonal Flange Head Cap Screw offers several benefits. The improved load distribution provided by the flange head ensures that the screw can handle higher loads without deformation. The enhanced fastening security reduces the risk of components loosening over time, even under vibration. Furthermore, the material properties of the screw contribute to its resistance to corrosion and wear, ensuring long-term reliability.

Installation Guidelines

Proper installation of the Hexagonal Flange Head Cap Screw is crucial for optimal performance. The screw should be installed using the appropriate torque specifications to ensure it is tightened to the correct level without over-tightening, which could lead to stripping or damage. Best practices include using a torque wrench to achieve the specified torque and ensuring that the components being fastened are clean and free of debris to prevent galling or seizing.

Troubleshooting and Maintenance

Common issues with Hexagonal Flange Head Cap Screws include corrosion, stripping, and loosening. Corrosion can be addressed by applying a corrosion-resistant coating or using screws made from stainless steel. Stripping can often be prevented by using the correct torque specifications during installation. If a screw becomes loose, it should be re-tightened to the specified torque, and if it continues to loosen, it may need to be replaced. Regular inspection and maintenance can help identify and address these issues before they lead to component failure.

Cummins Overview

Cummins is a reputable manufacturer in the automotive industry, known for its commitment to producing high-quality components for heavy-duty trucks. With a history of innovation and excellence, Cummins has established itself as a leader in providing reliable and durable parts that enhance the performance and longevity of heavy-duty vehicles. Their components are designed to meet the rigorous demands of heavy-duty applications, ensuring that trucks operate efficiently and reliably.

Cummins Hexagonal Flange Head Cap Screw 4360070 in Engine Applications

The Cummins Hexagonal Flange Head Cap Screw, part number 4360070, is a critical component in various engine systems. This screw is designed to provide secure fastening in high-stress environments, ensuring the integrity and performance of the engine components it connects.

ISV (Nissan) Engines

In the ISV (Nissan) engines, the 4360070 screw is utilized in several key areas. Its robust design and hexagonal flange head provide a larger surface area for torque application, which is essential for maintaining the tight seals and secure connections required in engine assemblies. This screw is often used in applications where it needs to withstand significant mechanical stress and thermal variations, ensuring the longevity and reliability of the engine.

The precise fit and function of the 4360070 screw in ISV engines highlight its importance in maintaining the structural integrity and operational efficiency of the engine. Its use in these engines underscores the importance of high-quality fasteners in achieving optimal engine performance.

Role of Part 4360070 Hexagonal Flange Head Cap Screw in Engine Systems

The part 4360070 hexagonal flange head cap screw is integral in securing various components within engine systems, ensuring stability and proper function.

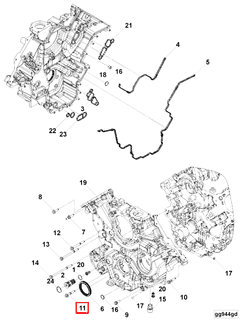

Front Sprocket Cover

In the assembly of the front sprocket cover, the 4360070 screw plays a significant role. It is used to fasten the cover to the engine block, providing a secure attachment that prevents the cover from becoming dislodged during operation. This is essential for maintaining the integrity of the engine’s timing system, as the front sprocket cover houses components like the timing chain or belt. Proper fastening ensures that these elements remain in correct alignment, contributing to the engine’s overall performance and longevity.

Long Block Kit

Within a long block kit, which typically includes the engine block, crankshaft, pistons, and other essential components, the 4360070 screw is employed to secure various accessories and ancillary parts. For instance, it may be used to attach sensors, brackets, or other components that are part of the long block assembly. The screw’s design, featuring a hexagonal flange head, allows for easy installation and removal using standard tools, facilitating maintenance and repair procedures. Its robust construction ensures that these attachments remain firm under the stresses of engine operation, contributing to the reliability of the long block kit.

Conclusion

The Cummins Hexagonal Flange Head Cap Screw, part number 4360070, is a vital component in heavy-duty truck and engine applications. Its robust design, high-strength material, and secure fastening capabilities ensure the structural integrity and performance of critical components. Proper installation and maintenance of this screw are essential for optimal performance and longevity of the vehicle.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.