4372600

Connecting Rod Cap Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

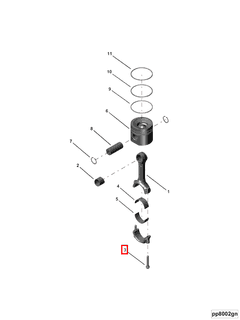

The Cummins 4372600 Connecting Rod Cap Screw is a specialized component designed for use in heavy-duty truck engines. Its purpose is to secure the connecting rod to the crankshaft, ensuring the efficient transfer of power from the piston to the crankshaft. This component plays a role in maintaining the structural integrity and operational efficiency of the engine.

Basic Concepts of Connecting Rod Cap Screws

A Connecting Rod Cap Screw is a fastener used to join the connecting rod cap to the connecting rod. This connection is vital for the proper functioning of the engine, as it allows the rod to pivot smoothly around the crankshaft. The screw must withstand high levels of stress and vibration, ensuring a secure and reliable connection throughout the engine’s operation 1.

Purpose of the 4372600 Connecting Rod Cap Screw

This part serves to firmly attach the connecting rod cap to the connecting rod, facilitating the transfer of force from the piston to the crankshaft. This secure attachment is important for the engine’s performance, as it ensures that the connecting rod operates within its designed parameters, contributing to the overall efficiency and reliability of the engine.

Key Features

The 4372600 is engineered with specific features to enhance its performance and durability. These include a precise material composition that offers high strength and resistance to wear, specialized threading that ensures a tight and secure fit, and design specifications that optimize its function within the engine environment.

Benefits

The use of this Cummins part provides several benefits. It contributes to improved engine reliability by ensuring a secure connection between the connecting rod and crankshaft. Additionally, it enhances the performance of the engine by maintaining the integrity of the connecting rod assembly, and it supports the longevity of the engine components through its durable construction.

Installation Process

Proper installation of the 4372600 involves several steps to ensure a secure and effective attachment. This includes cleaning the mating surfaces, applying the appropriate lubricant, positioning the screw correctly, and tightening it to the specified torque. Following these steps helps to prevent issues such as loosening or failure, ensuring the screw performs its intended function reliably.

Maintenance and Inspection

Routine maintenance and inspection of the 4372600 are recommended to ensure ongoing performance and to detect potential issues early. This may involve checking for signs of wear or damage, ensuring the screw is properly tightened, and addressing any issues promptly to maintain the integrity of the engine.

Troubleshooting Common Issues

Common problems associated with Connecting Rod Cap Screws include loosening or failure. Troubleshooting these issues may involve re-torquing the screw to the manufacturer’s specifications, inspecting for damage, and replacing the screw if necessary. Addressing these issues promptly can help to maintain the performance and reliability of the engine.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the heavy-duty truck and engine industry, known for its wide range of products and strong reputation for quality and reliability. The company has a long history of innovation and excellence, providing solutions that meet the demanding requirements of heavy-duty applications.

Connecting Rod Cap Screw in Cummins Engines

The Connecting Rod Cap Screw, part number 4372600, is a component in the assembly of Cummins engines, ensuring the secure attachment of the connecting rod to the crankshaft. This screw is designed to withstand high levels of stress and torque, which are common in engine operations.

Cummins QSK78 Engine

In the Cummins QSK78 engine, the Connecting Rod Cap Screw is integral to maintaining the structural integrity of the engine. This engine is known for its robust design and is often used in heavy-duty applications, such as marine and industrial settings. The screw’s role in this engine is to ensure that the connecting rod remains firmly attached to the crankshaft, preventing any potential failure that could lead to catastrophic engine damage.

Cummins CM500 Engine

Similarly, in the Cummins CM500 engine, the Connecting Rod Cap Screw is important for the proper functioning of the engine. The CM500 is a smaller, yet powerful engine, commonly used in various applications including agricultural and construction machinery. The screw’s design and material ensure that it can handle the specific stresses and operational conditions of this engine, maintaining the alignment and stability of the connecting rod.

Grouping of Engines

Both the QSK78 and CM500 engines belong to the Cummins family of engines, which are renowned for their reliability and performance. The use of the same Connecting Rod Cap Screw across these engines highlights Cummins’ commitment to standardization and quality. This standardization allows for easier maintenance and repair, as technicians can use the same tools and parts across different engine models, simplifying the process and reducing downtime.

Understanding the Role of Part 4372600 Connecting Rod Cap Screw in Engine Systems

The part 4372600 Connecting Rod Cap Screw is a component in the assembly and operation of various engine systems. Its primary function is to secure the connecting rod cap to the connecting rod, ensuring the integrity and stability of the engine’s moving parts.

Integration with Key Engine Components

-

Engine Piston and Connecting Rod: The connecting rod cap screw plays a role in maintaining the connection between the engine piston and the connecting rod. This secure attachment ensures that the piston’s linear motion is effectively translated into rotational motion of the crankshaft, a fundamental aspect of engine operation.

-

Cylinder and Cylinder Head: Proper fastening of the connecting rod cap is vital for the overall stability of the cylinder and cylinder head assembly. It helps in maintaining the precise alignment and movement of the piston within the cylinder, which is essential for efficient combustion and power generation.

-

Camshaft and Valve Train: Although indirectly related, the stability provided by the connecting rod cap screw influences the camshaft and valve train’s operation. A secure connecting rod assembly ensures smooth engine operation, which in turn supports the timing and efficiency of the valve events controlled by the camshaft.

-

Fuel Manifold and Injector Plumbing: The consistent and reliable operation of the engine, facilitated by the connecting rod cap screw, ensures that the fuel manifold and injector plumbing systems function optimally. This stability allows for precise fuel delivery and combustion, enhancing engine performance and efficiency.

-

Injector and Combustion Process: The secure attachment of the connecting rod cap contributes to the engine’s overall stability, which is crucial for the accurate timing and delivery of fuel by the injectors. This precision is essential for achieving optimal combustion efficiency and power output.

Conclusion

In summary, the part 4372600 Connecting Rod Cap Screw is a fundamental component that ensures the reliable and efficient operation of various engine systems. Its role in securing the connecting rod assembly directly impacts the performance and stability of the engine, influencing multiple interconnected components and processes.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.