4372963

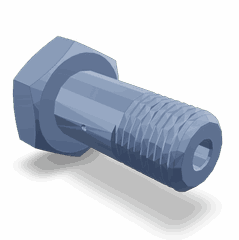

Banjo Connector Screw

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4372963 Banjo Connector Screw, manufactured by Cummins, is a critical component in commercial truck applications. Cummins, a renowned name in the industry, produces a range of parts designed to enhance the performance and reliability of commercial vehicles. This part is integral to the fluid systems within these trucks, ensuring efficient operation and durability.

Basic Concepts and Functionality

A Banjo Connector Screw is a fitting used in fluid systems to connect hoses or pipes to various components. It typically consists of a bolt with a banjo fitting attached, allowing for the secure connection of fluid lines. In a truck’s hydraulic or fuel system, this part facilitates the transfer of fluids under pressure, ensuring that the system operates smoothly and efficiently 1.

Purpose and Role in Truck Operation

The 4372963 Banjo Connector Screw connects hoses or pipes to critical components within the hydraulic or fuel system. This connection is vital for maintaining the integrity of the fluid pathways, ensuring that fluids are delivered where needed without leaks or disruptions. The screw’s design allows for a secure and reliable connection, which is essential for the consistent performance of the truck’s systems 2.

Key Features

This part is characterized by several key features that enhance its performance and durability. These include its material composition, typically made from high-strength steel to withstand the pressures and conditions within a truck’s fluid systems. The thread type is designed to provide a secure fit, while the sealing mechanisms ensure that there are no leaks. Additionally, the design specifications of the screw are tailored to meet the demands of commercial truck applications, ensuring long-term reliability 3.

Benefits

Using the 4372963 Banjo Connector Screw offers several benefits. One of the primary advantages is improved sealing, which prevents fluid leaks and ensures that the system operates efficiently. The screw is also designed for ease of installation, reducing the time and effort required during maintenance or repairs. Additionally, its resistance to corrosion enhances its longevity, even in harsh operating environments. The long-term reliability of the screw contributes to the overall performance and durability of the truck’s fluid systems 4.

Installation Process

Proper installation of the 4372963 Banjo Connector Screw involves several steps to ensure a secure fit. Begin by gathering the necessary tools, which may include a torque wrench and appropriate sockets. Clean the connection point to remove any debris or contaminants. Apply the recommended sealant to the threads of the screw to enhance the seal. Insert the screw into the banjo fitting and tighten it to the specified torque, ensuring that it is secure without over-tightening, which could damage the fitting or the threads.

Troubleshooting Common Issues

Common issues with Banjo Connector Screws may include leaks or improper sealing. To address these problems, first, ensure that the screw is tightened to the correct torque specification. Inspect the sealing surfaces for any damage or debris that may be preventing a proper seal. If leaks persist, the screw or the banjo fitting may need to be replaced. Regular inspection and maintenance can help identify and resolve these issues before they lead to more significant problems.

Maintenance Tips

To prolong the life of the 4372963 Banjo Connector Screw, regular maintenance is recommended. Inspect the screw and its connections at regular intervals to check for signs of wear, corrosion, or leaks. Clean the screw and its fittings as part of routine maintenance to remove any buildup that could affect performance. If any damage is detected, consider replacing the screw to prevent potential failures. Following these maintenance practices will help ensure the continued reliability of the truck’s fluid systems.

Compatibility and Applications

The 4372963 Banjo Connector Screw is designed for use within Cummins engines and other commercial truck systems. Its versatility allows it to be applied in various fluid systems, including hydraulic and fuel systems, across a range of commercial vehicles. This widespread compatibility underscores the screw’s importance in maintaining the efficiency and reliability of these systems.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its high-quality engines and components. Founded in 1919, Cummins has a long history of innovation and excellence, producing a wide range of products that power commercial vehicles, industrial equipment, and power generation systems. The company’s reputation for quality and reliability is reflected in its parts, including the 4372963 Banjo Connector Screw, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Engine Compatibility with Part 4372963

The Banjo Connector Screw, part number 4372963, manufactured by Cummins, is a crucial component in the fuel and hydraulic systems of various Cummins engines. This part is designed to ensure a secure and leak-free connection between hoses and fittings, which is essential for maintaining system integrity and performance.

K38 and K50 Engines

The K38 and K50 engines, known for their robust design and reliability, utilize the Banjo Connector Screw in their fuel and hydraulic systems. This part ensures that the connections between the hoses and the engine’s components are tight and secure, preventing any potential leaks that could compromise engine performance.

KTA38GC CM558

The KTA38GC CM558 engine, a variant of the KTA series, also incorporates the Banjo Connector Screw in its design. This engine is often used in heavy-duty applications, and the secure connections provided by this part are critical for maintaining the engine’s efficiency and longevity.

QSK45 CM500 and QSK60 CM500

Both the QSK45 CM500 and QSK60 CM500 engines benefit from the use of the Banjo Connector Screw. These engines are part of the QSK series, known for their high power output and reliability in various industrial applications. The secure connections provided by this part are essential for ensuring that these engines operate at peak performance.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines, which are part of the QSK60 series, also utilize the Banjo Connector Screw. These engines are designed for heavy-duty applications and require reliable connections to maintain their performance and durability. The secure fit provided by this part is crucial for these engines’ operation.

QSK60G

The QSK60G engine, another variant in the QSK60 series, also incorporates the Banjo Connector Screw. This engine is designed for high-performance applications and relies on the secure connections provided by this part to ensure optimal operation and longevity.

Role of Part 4372963 Banjo Connector Screw in Engine Systems

The 4372963 Banjo Connector Screw is instrumental in ensuring the efficient operation of various engine systems by providing secure and reliable connections. Its application spans across multiple components, enhancing the overall performance and reliability of the engine.

Turbocharger Systems

In turbocharger setups, the Banjo Connector Screw is used to connect the oil feed and return lines to the turbocharger. This connection is vital for maintaining the proper lubrication of the turbocharger bearings, which is essential for its efficient operation and longevity. The secure fitting provided by the Banjo Connector Screw ensures that oil flow is consistent and unimpeded, preventing any potential leaks that could lead to turbocharger failure.

Engine Kit Configurations

Within engine kits, the Banjo Connector Screw plays a significant role in connecting various oil passages. It ensures that oil is distributed evenly throughout the engine, lubricating critical components such as the crankshaft, camshaft, and valve train. This consistent oil distribution is essential for reducing friction and wear, thereby enhancing the engine’s durability and performance.

Pump Systems

In pump systems, particularly those involving raw water and auxiliary pumps, the Banjo Connector Screw is used to connect hoses and fittings. This ensures that the pump can operate efficiently by maintaining a secure and leak-free connection. Whether it’s a raw water pump used for cooling or an auxiliary pump for additional functions, the Banjo Connector Screw helps in sustaining the pump’s performance by ensuring that fluid flow is uninterrupted.

Auxiliary Cooling Systems

For auxiliary cooling systems, the Banjo Connector Screw is employed to connect coolant lines. This is particularly important in systems where additional cooling is required, such as in high-performance engines or those operating in extreme conditions. The secure connection provided by the Banjo Connector Screw ensures that coolant circulates effectively, maintaining optimal engine temperature and preventing overheating.

Water Pump Kits

In water pump kits, the Banjo Connector Screw is used to connect impeller housings and coolant passages. This ensures that the water pump can effectively circulate coolant throughout the engine, maintaining consistent temperature regulation. The reliable connection offered by the Banjo Connector Screw is essential for the water pump’s efficiency, contributing to the engine’s overall cooling performance.

Conclusion

Overall, the 4372963 Banjo Connector Screw is a fundamental component in various engine systems, providing the necessary secure connections that ensure the efficient operation and longevity of the engine. Its role in maintaining system integrity, enhancing performance, and ensuring reliability makes it an indispensable part in the maintenance and operation of commercial trucks and industrial engines.

-

Dempsey, Paul. Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill, 2018.

↩ -

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Viskup, Richard. Diesel and Gasoline Engines. IntechOpen, 2020.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.