This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4382888 High Temperature Screw is a specialized component manufactured by Cummins, a well-established name in the automotive industry. This screw is designed for use in commercial trucks, where it plays a significant role in ensuring the reliable operation of various systems within the vehicle.

Purpose and Function

This Cummins part serves a vital role in the operation of commercial trucks. It is utilized in applications where high temperatures and demanding conditions are prevalent. This screw helps secure components in place, ensuring they function correctly under stress. Its role contributes to the overall performance and efficiency of the truck by maintaining the integrity of critical assemblies.

Key Features

The 4382888 is distinguished by several key features. Its design incorporates materials that can withstand extreme temperatures, making it suitable for high-stress environments. The screw is crafted from durable materials, ensuring longevity and reliability. Additionally, it features a unique thread pattern that provides a secure fit, reducing the likelihood of loosening over time.

Benefits

Utilizing this part offers several advantages. Its high-temperature resistance ensures it remains functional in environments where other screws might fail. The screw’s durable construction contributes to improved vehicle reliability, reducing the need for frequent replacements. Furthermore, its secure fit enhances the performance of the assemblies it is part of, leading to more efficient vehicle operation.

Installation and Usage

Proper installation of this part is crucial for its effective function. It should be installed according to the manufacturer’s guidelines to ensure it is securely fastened and can withstand operational stresses. Users should follow specific instructions provided by Cummins to achieve the best results. Precautions during installation include ensuring the screw is tightened to the recommended torque specifications to prevent over-tightening, which could damage the screw or the components it secures.

Troubleshooting and Maintenance

Common issues with this Cummins part may include loosening or damage due to extreme conditions. Regular inspections can help identify these issues early. Maintenance tips include checking for signs of wear or corrosion and ensuring the screw remains tightened to the specified torque. If the screw shows signs of damage, it should be replaced to maintain the integrity of the assembly it is part of.

Safety Considerations

When working with this part, it is important to follow safety procedures. This includes wearing appropriate personal protective equipment (PPE) and ensuring the vehicle is safely supported during installation or maintenance work. Awareness of potential hazards, such as high temperatures or sharp edges, is crucial to prevent injuries.

Environmental Impact

Cummins is committed to minimizing the environmental impact of its products. The manufacturing process of the 4382888 incorporates measures to reduce waste and energy consumption. Additionally, the screw’s durable design contributes to reducing the need for frequent replacements, which can lower the overall environmental footprint.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry. Its product offerings span a wide range of applications, from commercial vehicles to industrial equipment, demonstrating a commitment to excellence and customer satisfaction.1

High Temperature Screw Compatibility with Cummins Engines

The High Temperature Screw part number 4382888, manufactured by Cummins, is designed to be compatible with a range of Cummins engines. This screw is engineered to withstand extreme temperatures, making it an essential component in maintaining the integrity and performance of the engines it is used with.

15N CM2380 M104B

The 15N CM2380 M104B engine benefits from the use of the High Temperature Screw 4382888. This screw is integral in securing various components under high-temperature conditions, ensuring that the engine operates efficiently and reliably.

QSK95 CM2350 K113

Similarly, the QSK95 CM2350 K113 engine also utilizes the High Temperature Screw 4382888. This screw plays a crucial role in maintaining the structural integrity of the engine by securing parts that are exposed to intense heat, thereby preventing failure and extending the engine’s lifespan.

Grouped Engines

Both the 15N CM2380 M104B and QSK95 CM2350 K113 engines share a common requirement for high-temperature components due to their operational environments. The High Temperature Screw 4382888 is specifically designed to meet these demands, ensuring that both engines can perform optimally under challenging conditions.

Role of Part 4382888 High Temperature Screw in Engine Systems

The part 4382888 High Temperature Screw is an essential component in the assembly and maintenance of various engine systems, particularly in the context of aftertreatment devices. This screw is designed to withstand extreme temperatures, making it suitable for use in environments where other fasteners might fail.

In the context of aftertreatment devices, the 4382888 screw is utilized to secure components that are exposed to high temperatures during operation. These devices are integral to reducing emissions and ensuring that the engine meets environmental regulations. The screw’s high-temperature resistance ensures that the aftertreatment device remains intact and functions effectively throughout its operational life.

When it comes to device service kits, the 4382888 screw often plays a role in the reassembly process after maintenance or repair. Its durability and temperature resistance make it a reliable choice for ensuring that all components are securely fastened, which is vital for the device’s performance and longevity.

In the assembly of aftertreatment systems, the 4382888 screw is used to connect various parts that are subject to thermal stress. This includes securing catalytic converters, diesel particulate filters (DPFs), and selective catalytic reduction (SCR) systems. The screw’s ability to maintain structural integrity under high temperatures is key to the overall effectiveness of these systems.

The water transfer tube is another component where the 4382888 screw finds application. In systems where water or other fluids are used to manage temperature or aid in the aftertreatment process, the screw ensures that the tube connections remain secure, even under the stress of thermal expansion and contraction.

Overall, the 4382888 High Temperature Screw is a fundamental element in the construction and maintenance of engine systems, particularly those involving aftertreatment technologies. Its role in securing components under high-temperature conditions is indispensable for the efficient and reliable operation of modern engines.

Conclusion

The 4382888 High Temperature Screw is a critical component in the automotive industry, particularly for commercial trucks and Cummins engines. Its design, featuring high-temperature resistance and durable construction, ensures reliable performance in demanding environments. Proper installation, regular maintenance, and adherence to safety procedures are essential for maximizing its benefits and ensuring the longevity of the systems it supports.

-

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩

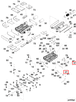

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.