This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The High Temperature Screw (Part #4382926) by Cummins is a specialized component designed for use in heavy-duty truck operations. This screw is engineered to withstand extreme temperatures and demanding conditions, ensuring reliable performance in critical applications. Its role in maintaining the integrity and efficiency of heavy-duty truck systems underscores its significance in the industry 1.

Purpose and Function

This Cummins part plays a role in securing and maintaining the alignment of components within heavy-duty truck engines and exhaust systems. It is specifically designed to operate under high thermal stress, ensuring that connections remain secure even in the presence of intense heat. This screw supports various systems, including exhaust manifolds, turbochargers, and other high-temperature applications, contributing to the overall performance and reliability of the truck 2.

Key Features

The High Temperature Screw is constructed from a durable alloy that offers superior resistance to heat and corrosion. Its design includes a threaded shaft that provides a strong and secure fit, minimizing the risk of loosening over time. The screw’s material composition and precise engineering allow it to maintain structural integrity in environments where other fasteners might fail. Additionally, the screw features a coated surface that enhances its resistance to thermal degradation and oxidation 3.

Benefits

The advantages of using the High Temperature Screw include improved durability and reliability in extreme conditions. Its robust construction ensures long-lasting performance, reducing the frequency of replacements and maintenance interventions. Fleet operators can experience potential cost savings due to the screw’s extended service life and reduced downtime. Moreover, the screw’s ability to withstand high temperatures contributes to the overall efficiency and safety of the truck’s operation.

Installation and Usage

Proper installation of the High Temperature Screw is vital to ensure optimal performance and longevity. It is recommended to follow manufacturer guidelines for torque specifications to achieve the correct tension without overtightening, which could lead to damage. Using the appropriate tools and techniques during installation will help maintain the screw’s integrity and functionality. It is also important to ensure that mating surfaces are clean and free from contaminants to promote a secure fit.

Maintenance and Troubleshooting

Regular maintenance of the High Temperature Screw involves inspecting it for signs of wear, corrosion, or loosening. Any detected issues should be addressed promptly to prevent further damage or failure. Common troubleshooting procedures include re-torquing the screw to the specified settings and replacing it if there are indications of significant wear or damage. Keeping detailed maintenance records can aid in identifying patterns or recurring issues, allowing for proactive management.

Manufacturer Overview

Cummins is a renowned manufacturer with a long-standing reputation in the automotive and heavy-duty truck industry. The company is committed to producing high-quality components that meet the rigorous demands of modern transportation. Cummins’ expertise in engineering and manufacturing ensures that their products, including the High Temperature Screw, deliver reliable performance and durability. Their dedication to innovation and customer satisfaction has established them as a trusted name in the industry.

Compatibility with Cummins Engines

The High Temperature Screw part number 4382926, manufactured by Cummins, is designed to fit seamlessly within a range of Cummins engines, ensuring optimal performance and durability under extreme conditions. This screw is engineered to withstand high temperatures, making it an essential component for maintaining the integrity and functionality of the engine systems it is used in.

QSK95 and CM2350 Engines

The QSK95 and CM2350 engines, both part of Cummins’ robust lineup, benefit significantly from the use of the 4382926 High Temperature Screw. These engines are known for their reliability and efficiency in various applications, from marine to industrial use. The screw’s design ensures that it can endure the rigorous demands of these engines, providing a secure and stable connection in high-stress environments.

K113 Engine

The K113 engine, another member of Cummins’ esteemed engine family, also integrates the 4382926 High Temperature Screw into its construction. This engine is particularly valued for its power and efficiency, making it a preferred choice for heavy-duty applications. The screw’s ability to maintain its structural integrity at elevated temperatures is crucial for the K113 engine’s performance, ensuring that it operates smoothly and reliably under demanding conditions.

Role in Various Components

The High Temperature Screw is instrumental in securing various components within heavy-duty truck systems. Its high-temperature capability ensures it maintains integrity under the extreme conditions generated during operations.

Aftertreatment Bracket

The screw is essential for mounting the aftertreatment device to the vehicle’s chassis. Its high-temperature resistance ensures it maintains integrity under the extreme conditions generated during the aftertreatment processes, such as those involving Diesel Particulate Filters (DPF) or Selective Catalytic Reduction (SCR) systems.

Aftertreatment Device

In the context of the aftertreatment device, the screw plays a significant role in maintaining the structural stability of the device. Whether it is a DPF, SCR, or any other aftertreatment component, these devices operate under high temperatures and pressures. The screw’s high-temperature resistance ensures that the device remains securely fastened, preventing any potential detachment or misalignment that could compromise the efficiency of the aftertreatment process.

Device

The screw is often used in various sub-components that require high-temperature fasteners. This includes sensors, actuators, and other critical components within the aftertreatment system. The screw’s reliability under thermal stress ensures that these devices function correctly, contributing to the overall performance and durability of the aftertreatment system.

Aftertreatment System

In the comprehensive aftertreatment system, the screw is a fundamental component in ensuring the system’s structural and functional integrity. It is used in multiple points within the system, from mounting brackets to securing individual components. Its high-temperature resistance is vital for maintaining the system’s effectiveness in reducing emissions and complying with environmental regulations.

Service Kit

Within a service kit designed for aftertreatment systems, the screw is often included to replace worn or damaged fasteners. The screw’s high-temperature properties make it an ideal candidate for ensuring that the service kit can restore the aftertreatment system to its optimal condition. This is particularly important during maintenance procedures where the system is exposed to high temperatures during operation or testing.

Conclusion

The High Temperature Screw (Part #4382926) by Cummins is a critical component in the maintenance and operation of heavy-duty truck engines and aftertreatment systems. Its robust design, high-temperature resistance, and compatibility with various Cummins engines make it an indispensable part for ensuring the reliability and efficiency of these systems. Proper installation, maintenance, and understanding of its role in different components are essential for maximizing its benefits and ensuring the longevity of the systems it supports.

SPECIFICATIONS

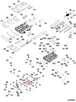

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.