4385117

High Temperature Screw

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The High Temperature Screw 4385117 is a specialized component manufactured by Cummins, a leader in the automotive and heavy-duty truck industry. This screw is designed to withstand extreme temperatures and demanding conditions, contributing to the efficiency and durability of trucks.

Purpose and Function

This Cummins part plays a role in securing critical components within the truck’s engine system. It is designed for applications where high temperatures and mechanical stress are common, ensuring the integrity of the engine’s components. Its applications range from fastening engine parts to securing components in the exhaust system.

Key Features

The 4385117 is crafted from high-grade materials that offer superior strength and durability. Its composition includes alloys that resist corrosion and maintain structural integrity under high temperatures. The screw features a precision-machined thread that ensures a tight and secure fit, minimizing the risk of loosening over time. Additionally, it may include special coatings or treatments that enhance its resistance to heat and wear 1.

Benefits

One of the primary advantages of the High Temperature Screw 4385117 is its ability to withstand extreme temperatures without degrading. This characteristic ensures that the screw remains functional in high-stress environments, reducing the need for frequent replacements. Its durable construction also contributes to improved efficiency in truck operations, as it helps maintain the optimal performance of engine components. Furthermore, the screw’s reliable performance enhances the overall safety and reliability of the vehicle 2.

Installation Process

Installing the High Temperature Screw 4385117 requires careful attention to detail to ensure proper integration into the truck’s system. Begin by identifying the correct location for the screw and cleaning the area to remove any debris or old fasteners. Use the appropriate torque wrench to install the screw, ensuring it is tightened to the manufacturer’s specified torque rating. This step is crucial to avoid over-tightening, which can damage the screw or the components it secures. Follow the manufacturer’s guidelines for any additional steps or precautions.

Maintenance Tips

To ensure the longevity and optimal performance of the High Temperature Screw 4385117, regular maintenance is recommended. Inspect the screw periodically for signs of wear, corrosion, or loosening. Clean the screw and surrounding area to remove any buildup that could affect its performance. If the screw shows signs of damage or excessive wear, it should be replaced promptly to prevent potential failures. Adhering to these maintenance practices will help maintain the screw’s integrity and contribute to the overall reliability of the truck.

Troubleshooting Common Issues

Occasionally, issues may arise with the High Temperature Screw 4385117. Common problems include loosening, corrosion, or damage from extreme temperatures. To address these issues, first, inspect the screw and the components it secures for any visible signs of damage. If corrosion is present, clean the affected area thoroughly and apply a protective coating if necessary. For screws that have loosened, re-tighten them to the specified torque rating. If the screw is damaged, replacement is recommended to ensure the continued safe operation of the truck.

Cummins Overview

Cummins is a well-established manufacturer with a strong reputation in the automotive and heavy-duty truck industry. Founded in 1919, Cummins has a long history of innovation and excellence in producing high-quality components. The company is known for its commitment to reliability, performance, and customer satisfaction. Cummins’ extensive product line includes engines, powertrains, and various automotive components, all designed to meet the demanding requirements of commercial and industrial applications.

Compatibility with Cummins Engines

The High Temperature Screw 4385117 is designed to fit seamlessly within various Cummins engine models, ensuring durability and reliability under high-stress environments.

QSK95 and CM2350 Engines

The QSK95 and CM2350 engines are part of Cummins’ heavy-duty diesel engine lineup, known for their robust performance in demanding applications. The High Temperature Screw 4385117 is specifically designed to integrate with these engines, providing a secure fastening solution that can endure the intense heat and pressure typical in these high-performance settings.

K113 Engine

The K113 engine, another member of Cummins’ extensive engine family, also benefits from the High Temperature Screw 4385117. This screw is engineered to maintain its structural integrity and functionality in the K113’s operational environment, ensuring that critical components remain tightly secured even under extreme conditions.

Grouping of Engines

The QSK95, CM2350, and K113 engines share common design principles and operational requirements, making the High Temperature Screw 4385117 a versatile and essential component across these models. Its compatibility with these engines underscores Cummins’ commitment to providing high-quality, reliable parts that meet the rigorous demands of their engine lineup.

Role in Engine Systems

The High Temperature Screw 4385117 is integral to the secure assembly and disassembly of various engine components, particularly in high-stress environments. Its application spans across multiple systems, ensuring robust connections that withstand extreme conditions.

Aftertreatment Device

In the aftertreatment device, the High Temperature Screw 4385117 is employed to connect critical components such as the Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) systems. These connections must endure high temperatures and pressures, making the screw essential for maintaining the integrity of the aftertreatment system. They facilitate easy serviceability, allowing for quick and reliable component replacement during maintenance procedures.

Aftertreatment Service Kit

When it comes to the aftertreatment service kit, the High Temperature Screw 4385117 plays a significant role in ensuring that all components within the kit are securely fastened. This includes connections to sensors, actuators, and various piping elements. The screw’s ability to maintain a tight seal under high temperatures ensures that the aftertreatment system operates efficiently, reducing the risk of leaks and enhancing overall performance.

General Device Applications

Across various devices within the engine system, the High Temperature Screw 4385117 is used to connect components that experience thermal cycling and mechanical stress. This includes connections to turbochargers, exhaust manifolds, and intercoolers. The screw’s design allows for repeated assembly and disassembly without compromising the connection’s integrity, which is vital for routine maintenance and repairs.

Summary of Component Integration

The integration of the High Temperature Screw 4385117 into these engine systems underscores its importance in ensuring reliable and durable connections. Its application in aftertreatment devices, service kits, and general device components highlights its versatility and essential role in maintaining the performance and longevity of engine systems.

Conclusion

The High Temperature Screw 4385117 by Cummins is a critical component designed to withstand extreme conditions and ensure the reliability and durability of truck engine systems. Its robust construction, precise engineering, and compatibility with various Cummins engines make it an indispensable part of commercial and industrial applications.

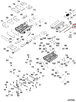

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.