This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

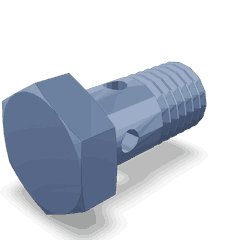

The 4897526 Banjo Connector Screw, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part is integral to the vehicle’s systems, particularly in fluid transfer applications. It facilitates the secure connection of hoses and pipes, ensuring the efficient and reliable transfer of fluids within the truck’s system.

Function and Operation

The Banjo Connector Screw operates by creating a sealed connection between fluid lines, such as those used in hydraulic or brake systems. It employs a unique design that allows for the passage of fluid while maintaining a tight seal. The screw’s role is vital in managing fluid dynamics, ensuring that the system operates under the correct pressure and flow conditions. This is achieved through precise engineering that accommodates the expansion and contraction of fluids under varying temperatures and pressures 1.

Key Features

This Cummins part is constructed from high-quality materials, typically steel or stainless steel, which provide durability and resistance to corrosion. It features a specific thread type that ensures a secure fit within the system’s components. Unique design elements, such as the banjo fitting itself, enhance the screw’s performance by allowing for easy connection and disconnection of fluid lines while maintaining a leak-proof seal 2.

Role in Truck Operation

In the operation of a truck, the 4897526 plays a significant role in fluid transfer systems. It is involved in critical applications such as brake systems, where it ensures the reliable transfer of brake fluid, and in hydraulic systems, where it maintains system pressure and flow. The screw’s ability to create and maintain a secure connection is fundamental to the safe and efficient operation of these systems 3.

Benefits of Using Banjo Connector Screws

Banjo Connector Screws offer several advantages, including effective leak prevention due to their sealed design, which minimizes the risk of fluid loss. They are also designed for ease of installation, allowing for quick and straightforward connection of fluid lines. Maintenance benefits include the screw’s durability and resistance to wear, contributing to the overall efficiency and reliability of the truck.

Installation and Maintenance

Proper installation of the 4897526 involves ensuring a clean and undamaged connection surface, using the correct torque specifications to secure the screw, and verifying the seal integrity after installation. Maintenance tips include periodic checks for signs of wear or corrosion, ensuring connections remain tight, and replacing the screw as necessary to maintain system integrity.

Troubleshooting Common Issues

Common issues with Banjo Connector Screws may include leaks or corrosion. Troubleshooting these problems involves inspecting the connection for signs of damage or wear, ensuring the screw is properly torqued, and checking for any obstructions in the fluid lines. Solutions may range from tightening the connection to replacing the screw if it is found to be damaged or worn.

Safety Considerations

Improper installation or maintenance of the 4897526 can lead to safety implications, including fluid leaks or system failure. It is important to follow manufacturer guidelines for installation and maintenance to ensure the component functions correctly and safely. Regular inspections and adherence to replacement intervals are crucial for preventing accidents related to fluid system failures.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established itself as a trusted name in the automotive industry. The company’s commitment to excellence is reflected in its wide range of products, including the 4897526, which is designed to meet the demanding requirements of commercial truck applications.

Application in Cummins Engines

ISB CM850 Engines

In the ISB CM850 engines, the Banjo Connector Screw is utilized in several key areas where secure connections are paramount. This includes, but is not limited to, fuel lines, oil lines, and coolant lines. The screw’s design allows for a tight seal, preventing any leakage that could compromise engine performance or lead to potential safety hazards. The precision engineering of the 4897526 ensures that it fits seamlessly with the engine’s design, providing a reliable connection that can withstand the rigors of engine operation.

ISBE CM800 Engines

Similarly, in the ISBE CM800 engines, the Banjo Connector Screw is employed in critical fluid line connections. Given the robust nature of the ISBE CM800 engines, the 4897526 is designed to meet the stringent demands of these engines. Its application in the ISBE CM800 series ensures that all fluid lines are securely fastened, contributing to the overall efficiency and longevity of the engine. The screw’s ability to create a tight seal is essential in preventing leaks, which can be particularly important in high-pressure environments.

Role of 4897526 in Engine Systems

The 4897526 is an essential component in various engine systems, facilitating the secure connection of different tubes and passages. Its applications span across several key areas within the engine, ensuring efficient operation and maintenance.

Breather System Integration

In the breather system, the 4897526 is utilized to connect the breather tube to the crankcase. This connection allows for the release of pressure built up within the crankcase, which is vital for maintaining optimal engine performance. The secure fitting provided by the screw ensures that no leaks occur, which could lead to contamination of the crankcase environment.

Fuel Drain Tube Connection

For the fuel drain tube, the 4897526 plays a significant role in connecting the tube to the fuel system. This ensures that any excess fuel can be safely drained away from the engine, preventing potential fuel buildup that could affect engine efficiency and safety.

Lubricating Oil Drain Tube Assembly

In the lubricating oil system, the screw is employed to connect the lubricating oil drain tube to the engine. This connection is imperative for the periodic draining of used oil, which is necessary for maintaining the lubrication system’s effectiveness. The secure connection prevents oil leaks, ensuring that the engine remains well-lubricated and operates smoothly.

Upper Engine Gasket Set Application

When dealing with the upper engine gasket set, the 4897526 is used to connect various passages that require a sealed connection. This includes connections to the vent tube, where it ensures that any gases or fluids are properly directed away from the engine components, contributing to the overall integrity of the engine’s sealing system.

Vent Tube Attachment

Finally, in the vent tube system, the screw is crucial for connecting the vent tube to other engine components. This connection allows for the venting of gases from the engine, which is essential for maintaining pressure balance and preventing the buildup of harmful gases within the engine compartment.

Conclusion

Overall, the 4897526 Banjo Connector Screw is a versatile component that enhances the functionality and reliability of various engine systems by providing secure and leak-proof connections. Its role in maintaining the integrity of fluid lines and connections is critical for the efficient and safe operation of commercial trucks and Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.