This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4900220 Captive Washer Cap Screw is a specialized fastener designed for use in heavy-duty truck applications. Its purpose is to provide secure and reliable fastening in environments where traditional screws might fail due to vibration, high stress, or exposure to the elements. The significance of this component lies in its ability to enhance the durability and performance of heavy-duty trucks, ensuring that critical components remain securely fastened under demanding conditions 1.

Basic Concepts of Captive Washer Cap Screws

A Captive Washer Cap Screw is a type of fastener that incorporates a washer directly into the screw design. This integration ensures that the washer remains in place during installation, reducing the risk of loss and ensuring consistent torque application. In the automotive industry, these screws are commonly used in applications where vibration resistance and secure fastening are paramount. The captive washer design helps to distribute pressure more evenly across the fastened surfaces, enhancing the overall stability and longevity of the connection 2.

Purpose and Role in Truck Operation

The Cummins 4900220 Captive Washer Cap Screw plays a specific role in the operation and maintenance of heavy-duty trucks. It is designed to fasten components that are subject to significant stress and vibration, such as engine mounts, exhaust systems, and chassis parts. By providing a secure and vibration-resistant connection, this screw contributes to the overall reliability and performance of the truck. Its use helps to prevent loosening of critical components, which can lead to mechanical failures and increased maintenance costs 3.

Key Features

The Cummins 4900220 Captive Washer Cap Screw boasts several key features that distinguish it from other fasteners. Its design includes an integrated washer that ensures consistent torque application and reduces the risk of washer loss during installation. The screw is typically made from high-strength materials, such as alloy steel, to withstand the rigors of heavy-duty truck applications. Additionally, the screw may feature a corrosion-resistant coating to enhance its durability in harsh environments.

Benefits

The Cummins 4900220 Captive Washer Cap Screw offers several benefits that make it an ideal choice for heavy-duty truck applications. Its integrated washer design simplifies the installation process, reducing the likelihood of errors and ensuring a secure connection. The high-strength material and corrosion-resistant coating enhance the screw’s reliability and longevity, even in demanding conditions. Furthermore, the vibration-resistant properties of the screw help to maintain the integrity of critical connections, contributing to the overall performance and safety of the truck.

Installation Process

Proper installation of the Cummins 4900220 Captive Washer Cap Screw is crucial to ensure its effectiveness. The installation process typically involves the following steps:

- Preparation: Ensure that the mating surfaces are clean and free of debris.

- Alignment: Align the screw with the designated hole in the component.

- Insertion: Insert the screw into the hole, ensuring that the captive washer is properly positioned.

- Tightening: Use a torque wrench to tighten the screw to the manufacturer’s specified torque settings. This ensures that the connection is secure without over-tightening, which could damage the components.

- Inspection: Inspect the installation to confirm that the screw is properly seated and the connection is secure.

Common Applications

The Cummins 4900220 Captive Washer Cap Screw is commonly used in various applications within heavy-duty trucks. Typical uses include fastening engine mounts, securing exhaust system components, and attaching chassis parts. Its versatility and reliability make it a preferred choice for applications where vibration resistance and secure fastening are critical.

Troubleshooting and Maintenance

To ensure the longevity and optimal performance of the Cummins 4900220 Captive Washer Cap Screw, regular maintenance and troubleshooting are important. Common issues may include loosening due to vibration or corrosion. To address these issues:

- Regular Inspection: Periodically inspect the screws for signs of loosening or corrosion.

- Re-tightening: If loosening is detected, re-tighten the screw to the specified torque settings.

- Corrosion Prevention: Apply a corrosion-resistant coating or lubricant to the screw and surrounding areas to prevent corrosion.

- Replacement: If significant corrosion or damage is observed, replace the screw to maintain the integrity of the connection.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industries. The company’s commitment to excellence is reflected in its extensive range of components, including the Cummins 4900220 Captive Washer Cap Screw, which is designed to meet the rigorous demands of heavy-duty applications.

Captive Washer Cap Screw (Part 4900220) in Cummins Engines

The Captive Washer Cap Screw, identified as part number 4900220, is a critical component in various Cummins engines. This part is designed to secure and stabilize different engine parts, ensuring the engine operates smoothly and efficiently. Here’s how it fits into the Cummins engine lineup:

A1400 and A1700 Engines

In the A1400 and A1700 engines, the Captive Washer Cap Screw is used to secure various engine components, including the cylinder head and other critical assemblies. Its design ensures that these parts remain tightly fastened, preventing any movement that could lead to engine failure or reduced performance.

A2000 and A2300 Engines

For the A2000 and A2300 engines, the Captive Washer Cap Screw plays a similar role. It is employed in securing the engine’s structural components, ensuring that all parts are held firmly in place. This is particularly important in these engines, where the increased power output and torque demand more robust fastening solutions.

Common Usage Across Engines

Across all these engines, the Captive Washer Cap Screw is utilized in areas where high reliability and durability are essential. Its design includes a captive washer that stays in place, preventing loss during assembly or maintenance, which is crucial for maintaining engine integrity.

The use of this part in Cummins engines highlights the manufacturer’s commitment to quality and reliability, ensuring that each engine component is securely fastened and performs optimally under various operating conditions.

Role of Part 4900220 Captive Washer Cap Screw in Engine Systems

The part 4900220 Captive Washer Cap Screw is integral to the assembly and secure functioning of various engine components.

In the block of an engine, this screw plays a significant role in fastening components that are essential for the structural integrity and operational efficiency of the engine. It ensures that parts remain securely in place, minimizing the risk of vibrations or movement that could lead to wear or failure.

When considering the cylinder, the 4900220 Captive Washer Cap Screw is often used to secure components that are critical for the cylinder’s performance. This includes attaching parts that facilitate the sealing and compression processes within the cylinder, ensuring optimal combustion and power output.

In the cylinder block, this screw is employed to fasten various attachments and accessories. Its role is to provide a stable and reliable connection, which is vital for the overall durability and performance of the cylinder block.

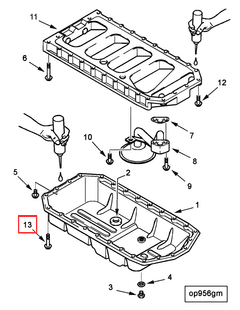

The oil pan of an engine also benefits from the use of the 4900220 Captive Washer Cap Screw. It is commonly used to secure the oil pan to the engine block, ensuring a tight seal that prevents oil leaks. This is essential for maintaining the lubrication system’s integrity, which is fundamental for the engine’s longevity and efficiency.

Lastly, in the broader context of the pan (which can refer to various pans within the engine system, including the oil pan), this screw ensures that the pan remains securely attached. This is important for containing fluids and preventing spills, which could lead to engine damage or environmental hazards.

Overall, the 4900220 Captive Washer Cap Screw is a versatile and reliable component that enhances the secure assembly and operational stability of various engine systems.

Conclusion

The Cummins 4900220 Captive Washer Cap Screw is a vital component in heavy-duty truck and engine applications. Its design, featuring an integrated washer, ensures consistent torque application and reduces the risk of washer loss during installation. Made from high-strength materials and often coated for corrosion resistance, this screw provides reliable and durable fastening solutions. Proper installation and regular maintenance are essential to ensure its effectiveness and longevity. The use of this part in Cummins engines underscores the manufacturer’s commitment to quality and reliability, contributing to the overall performance and safety of heavy-duty vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.