This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Hexagon Flange Head Cap Screw, identified by part number 4900252, is a component manufactured by Cummins, a well-regarded name in the commercial truck industry. This screw is integral to the assembly and maintenance of various truck components, ensuring secure fastening and reliable performance under demanding conditions.

Basic Concepts

A Hexagon Flange Head Cap Screw is a type of fastener characterized by its hexagonal head and a flange beneath the head. The hexagonal head allows for efficient torque application using standard tools, while the flange provides additional surface area to distribute load and prevent the screw from sinking into softer materials. In the context of truck mechanics, this design facilitates secure and stable connections, essential for the integrity and safety of truck components 1.

Purpose and Role in Truck Operation

This Cummins part plays a significant role in the operation of commercial trucks. It is used in various applications, including securing engine components, attaching body panels, and fastening chassis parts. Its design ensures that critical connections remain intact under the stress and vibration experienced during truck operation, contributing to the overall reliability and safety of the vehicle 2.

Key Features

The 4900252 boasts several key features that enhance its functionality. Its hexagonal head design allows for straightforward and precise torque application, reducing the risk of damage to the screw or surrounding components. The flange beneath the head provides additional bearing surface, which helps in distributing the load and preventing the screw from pulling through the material. Additionally, the screw is typically made from high-strength materials, ensuring durability and resistance to corrosion, which is vital for long-term performance in harsh operating environments 3.

Benefits

This part offers several benefits that make it a preferred choice for truck mechanics. Its robust construction and high-strength material contribute to enhanced durability, allowing it to withstand the rigors of commercial truck use. The design of the screw also provides improved fastening capabilities, ensuring secure connections that resist loosening over time. Furthermore, the flange feature helps in maintaining a consistent and even load distribution, which is essential for the longevity and performance of truck components 4.

Installation and Usage

Proper installation of the 4900252 is vital to ensure its effectiveness and longevity. It is recommended to use the appropriate torque specifications provided by the manufacturer to avoid over-tightening or under-tightening, both of which can lead to issues such as stripping or loosening. Best practices include cleaning the installation surface to remove any debris or contaminants that could affect the screw’s performance and using a torque wrench for accurate torque application.

Troubleshooting and Maintenance

Common issues with the 4900252 may include loosening due to vibration or corrosion. Regular inspection and maintenance can help identify and address these issues promptly. If corrosion is detected, it is advisable to replace the screw to prevent further degradation. Additionally, ensuring that all screws are tightened to the manufacturer’s specified torque can help maintain secure connections and prevent loosening.

Cummins Overview

Cummins is a renowned manufacturer with a long-standing reputation in the commercial truck industry. The company is known for its commitment to quality, innovation, and customer satisfaction. Cummins’ extensive history and expertise in engine and component manufacturing underscore its position as a trusted provider of reliable and high-performance parts, including the 4900252.

Cummins Hexagon Flange Head Cap Screw 4900252 in Engine Applications

The Cummins Hexagon Flange Head Cap Screw, part number 4900252, is a critical component in the assembly and maintenance of various engine models. This part is designed to provide a secure fastening solution, ensuring that engine components remain tightly secured under operational stresses.

A1400 and A1700 Engines

In the A1400 and A1700 engines, the 4900252 screw is often used in applications where a robust connection is necessary. These engines, known for their reliability and efficiency, benefit from the precision and strength offered by this screw. The flange head design allows for a larger surface area, distributing the load more evenly and reducing the risk of stripping or loosening over time.

A2000 and A2300 Engines

For the A2000 and A2300 engines, the 4900252 screw plays a similar role but is typically employed in more demanding environments. These engines, with their higher power outputs, require components that can withstand greater mechanical stresses. The hexagon flange head cap screw provides the necessary durability and strength, ensuring that critical engine parts remain securely fastened.

Common Applications

Across these engines, the 4900252 screw is commonly used in the following applications:

- Cylinder Head Bolting: Ensuring the cylinder heads are tightly sealed to prevent leaks and maintain compression.

- Engine Block Assembly: Securing various engine blocks and components to maintain structural integrity.

- Turbocharger Mounting: Attaching turbochargers to the engine, where precise alignment and secure fastening are crucial for performance and longevity.

The use of the 4900252 screw in these engines underscores its importance in maintaining the reliability and performance of Cummins engines. Its design and material properties make it an ideal choice for high-stress applications, ensuring that the engine components remain securely fastened under various operational conditions.

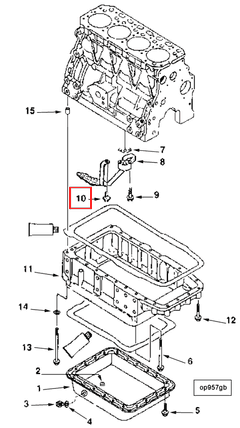

Role of Part 4900252 Hexagon Flange Head Cap Screw in Engine Systems

The 4900252 is instrumental in securing various components within engine systems, ensuring their proper function and alignment. This screw is commonly used in the fastening of the engine cover, providing a secure seal that protects internal components from contaminants and ensures optimal engine performance.

In the camshaft arrangement, the Hexagon Flange Head Cap Screw plays a significant role by securing the camshaft in place, which is essential for the precise timing of valve operations. This, in turn, affects the engine’s overall efficiency and power output.

When it comes to the front gear cover, this screw is used to maintain the integrity of the gear arrangement, which is vital for the transmission of power from the engine to other components. The secure fastening provided by the screw ensures that the gears operate smoothly and efficiently.

In the fuel pump mounting system, the Hexagon Flange Head Cap Screw is employed to fix the fuel pump securely to the engine. This is important for maintaining the fuel pump’s position and ensuring a consistent fuel supply to the engine, which is essential for combustion and engine operation.

The screw is also utilized in the oil pan and oil filter arrangements. By securely fastening these components, it ensures that the oil circulation system within the engine remains intact, which is vital for lubrication and cooling of engine parts.

Additionally, in the engine balancer and front engine balancer systems, the Hexagon Flange Head Cap Screw helps in maintaining the balance of rotating components. This balance is essential for reducing vibrations and ensuring smooth engine operation.

Lastly, in the lifting and filter components, this screw provides the necessary tension and security, ensuring that these parts function correctly and contribute to the engine’s overall performance.

Conclusion

The 4900252 Hexagon Flange Head Cap Screw is a vital component in the maintenance and operation of commercial trucks and engines. Its robust design, high-strength materials, and precise fastening capabilities ensure that critical connections remain secure under demanding conditions. Proper installation, regular maintenance, and adherence to manufacturer specifications are essential to maximize the performance and longevity of this part.

-

Rendle, S., & Randall, M. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Smil, V. (2010). The History and Impact of Diesel Engines and Gas Turbines. The MIT Press.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.